Our beginner’s introduction to CNC machining services!

If you’re new to the world of manufacturing and interested in learning about CNC machining, you’ve come to the right place. In this guide, we’ll provide an introduction to CNC machining services, explain the CNC machining process, discuss the materials and applications involved, explore different CNC machining techniques, and highlight the advantages of using CNC machining services.

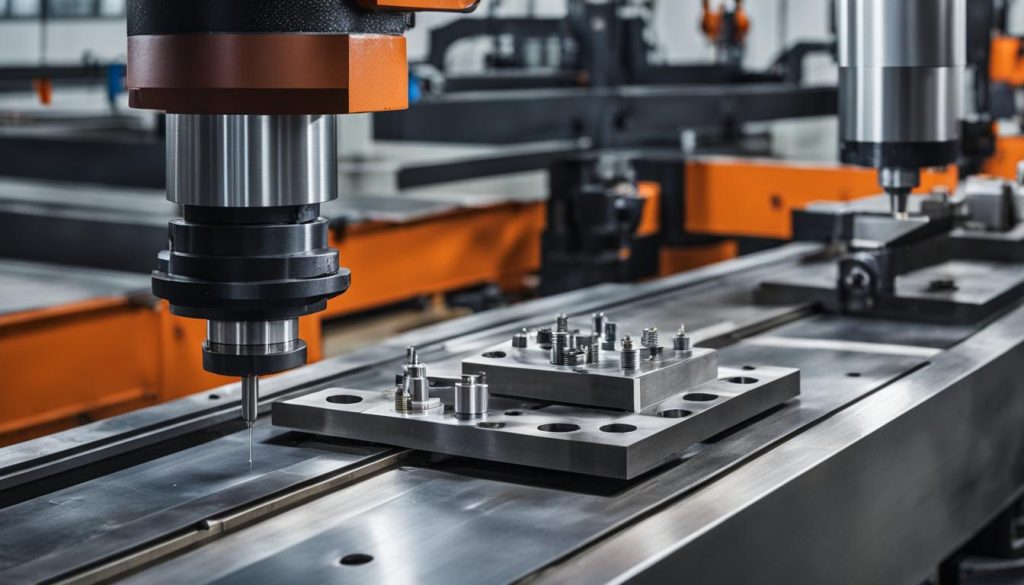

CNC machining, short for computer numerical control machining, is a manufacturing process that utilizes computer-controlled machines to produce precise and complex metal parts. By following a set of instructions programmed into the machine, CNC machining offers high precision, increased productivity, and the ability to create intricate designs.

During the CNC machining process, various techniques such as milling, turning, laser cutting, plasma cutting, and 3D printing can be employed to shape and form the desired parts. These techniques are commonly used in industries like automotive, aerospace, and medical devices to manufacture components with tight tolerances and intricate designs.

Using CNC machining services has several benefits, including the ability to achieve high precision, reduced scrap, and increased productivity. CNC machines are capable of working with a wide range of materials, including metals like aluminum and stainless steel, as well as plastics and wood. The applications of CNC machining are vast, ranging from manufacturing automotive parts and aerospace components to creating medical device components and intricate furniture designs.

As a beginner, understanding the basics of CNC machining services can help you make informed decisions when choosing a CNC machining service provider. Factors like quality and precision, turnaround time, and cost-effectiveness should be considered. Researching customer reviews and testimonials can also help you find a reputable CNC machining service provider that meets your specific needs.

Key Takeaways

- CNC machining is a computer-controlled manufacturing process that produces precise and complex metal parts.

- Techniques such as milling, turning, laser cutting, plasma cutting, and 3D printing are used in CNC machining services.

- CNC machining offers benefits such as high precision, reduced scrap, and increased productivity.

- Various materials like metals, plastics, and wood can be utilized in CNC machining.

- CNC machining services have applications in industries such as automotive, aerospace, and medical devices.

The History of CNC Machining

CNC machining has a rich history that dates back to the 18th century when the first milling machines were developed. However, it wasn’t until the 20th century that computer numerical control was introduced. The first CNC milling machine was invented in 1952, but it was still relatively primitive compared to modern CNC machines. Over the years, advancements in technology have revolutionized CNC machining, enabling machines to perform more complex operations with higher precision. Today, CNC machines are an integral part of the manufacturing industry, driving efficiency and productivity.

To understand the history of CNC machining, we must recognize the significance of its invention and the advancements that have shaped its development.

“The invention of the first CNC milling machine in 1952 marked a significant milestone in the history of machining.”

The first CNC milling machine, developed by John T. Parsons and Frank L. Stulen, was a breakthrough in precision engineering. This early machine used punched cards to control the movements of the cutting tools, allowing for greater accuracy and repeatability in machining operations.

Over the decades, CNC machining has undergone continual advancements and refinements. Computer technology has played a crucial role in enhancing the capabilities of CNC machines, enabling them to perform complex tasks with unrivaled precision.

Key Milestones in the Advancement of CNC Machining:

- In the 1950s and 1960s, CNC machines were primarily used in aerospace and defense industries for manufacturing complex components.

- In the 1970s and 1980s, microprocessors and computer-aided design (CAD) software revolutionized CNC machining, making it more accessible and flexible for a wide range of applications.

- In the 1990s, the integration of computer-aided manufacturing (CAM) software further improved the efficiency and accuracy of CNC machining.

- Today, CNC machines incorporate advanced technologies such as robotics, automation, and artificial intelligence, enabling them to operate autonomously and optimize production processes.

The evolution of CNC machining has opened up new horizons for manufacturing industries, allowing for the production of intricate and precise components that were once deemed unachievable. From automotive and aerospace to medical devices and consumer electronics, CNC machining plays a crucial role in meeting the demands of modern-day manufacturing.

How CNC Machining Works

CNC machining is a precise and efficient process that utilizes computer-controlled machines to remove material from a workpiece. Understanding how CNC machining works is essential to comprehend its capabilities and advantages.

The CNC machining process involves three primary components:

- Table: The table holds the workpiece securely in place during machining.

- CNC Machining Head: Equipped with various cutting tools, the CNC machining head performs the machining operations on the workpiece.

- Control Unit: The control unit, typically a computer, governs the movements of the milling cutter and controls the entire CNC machining process.

During CNC machining, the milling cutter moves across the workpiece according to a CNC milling program. This program is created using computer-aided manufacturing (CAM) software, which converts 3D models into CNC milling programs. CAM software automates the programming process, ensuring accuracy and saving time.

By combining computer-controlled milling with CAM software, CNC machining offers precise and reliable manufacturing solutions for a wide range of industries.

Advantages of CNC Machining Services

When it comes to manufacturing precision parts, CNC machining services offer a range of advantages that make them stand out from traditional machining methods. These benefits include:

Precision and Accuracy

The keyword in CNC machining is precision. With computer control and advanced technology, CNC machines can achieve high levels of accuracy, allowing for the creation of parts with tight tolerances. This precision ensures consistency and quality in every component produced, meeting the most demanding requirements of various industries.

Reduced Scrap

In traditional machining, human error is an inevitable risk that can result in wasted materials. CNC machining minimizes this risk by automating the process, reducing errors, and optimizing material utilization. This not only saves costs but also decreases waste, making CNC machining more sustainable and environmentally friendly.

Increased Productivity

With a computer-controlled process, CNC machines can operate at higher speeds compared to manual machining. This increased productivity allows for faster production cycles and shorter lead times, meeting tight deadlines without compromising on quality. CNC machining services provide efficient and timely solutions for businesses that require rapid production turnaround.

By leveraging the advantages of CNC machining services, manufacturers can benefit from improved precision, reduced scrap, and increased productivity. These advantages contribute to cost savings, shorter production cycles, and higher customer satisfaction.

| Advantages | Details |

|---|---|

| Precision and Accuracy | High levels of precision and accuracy, meeting tight tolerances and ensuring consistent quality. |

| Reduced Scrap | Minimization of human error, optimization of material utilization, and reduced waste. |

| Increased Productivity | Higher operating speeds, faster production cycles, and shorter lead times. |

Materials and Applications in CNC Machining

CNC machining is a versatile process that can be applied to a wide range of materials, including metals, plastics, and woods. Each material offers unique properties and characteristics that make it suitable for specific applications.

1. Metal Machining

Metal machining is one of the most common applications of CNC machining. It involves working with materials such as aluminum, stainless steel, and titanium. These metals are widely used in various industries due to their strength, durability, and excellent thermal and electrical conductivity. CNC machining allows for precise shaping and cutting of metal parts, making it ideal for automotive parts, aerospace components, and many other applications.

2. Plastic Machining

CNC machining is also well-suited for working with plastics, including materials like acrylic, polycarbonate, and nylon. Plastic machining offers advantages such as lightweight, corrosion resistance, and flexibility. CNC machines can create intricate designs and precise shapes, making it a preferred choice in industries such as electronics, consumer goods, and medical devices.

3. Wood Machining

CNC machining is not limited to metals and plastics; it can also be used to shape and carve wood. Wood machining is commonly employed in the creation of furniture, cabinetry, and architectural elements. CNC machines enable the production of complex designs and intricate details in wood, providing precision and efficiency in the manufacturing process.

4. CNC Machining Applications

CNC machining has a wide range of applications across various industries. Some examples include:

- Automotive Parts: CNC machining is widely used in the automotive industry to manufacture components such as engine parts, transmission components, and interior accessories.

- Marine Parts: CNC machining plays a crucial role in producing marine components, including boat structures, engine parts, and landing gear components.

- Robotic Device Components: CNC machining ensures the precision and accuracy required in the manufacture of robotic device components, such as Arms, instruments, and individual parts.

These are just a few examples of the diverse applications of CNC machining services. The versatility and precision of CNC machines make them indispensable in various manufacturing processes, enabling the production of high-quality, intricate components for a wide range of industries.

CNC Machining Techniques

CNC machining encompasses a range of techniques that are tailored to specific applications. Each technique offers unique advantages and is selected based on the requirements of the project.

Milling:

Milling is one of the most common CNC machining techniques. It involves using rotating cutting tools to remove material from a workpiece. This process allows for precise shaping and profiling of complex parts with high accuracy.

Turning:

The turning technique involves rotating the workpiece while a cutting tool shapes it. This process is ideal for creating cylindrical or conical shapes, such as shafts, pins, or rings. Turning is commonly used in CNC machining for applications that require rotational symmetry.

Laser Cutting:

Laser cutting utilizes a high-powered laser to cut through materials with precision. This technique is ideal for working with various materials, including metal, plastic, and wood. Laser cutting offers clean and accurate cuts with minimal material waste.

Plasma Cutting:

Plasma cutting involves the use of a plasma arc to cut conductive materials, such as steel, aluminum, and copper. This technique is known for its speed and ability to cut through thick materials. Plasma cutting is commonly used in industries that require fast and efficient metal cutting.

3D Printing (Additive Manufacturing):

3D printing, also known as additive manufacturing, is a revolutionary technique that builds objects layer by layer using various materials. It allows for the creation of complex geometries and intricate designs that are difficult or impossible to achieve with traditional machining methods.

CNC Machining Services: Precision Machining Pro

Precision Machining Pro is a leading CNC machining service provider that specializes in high-precision machining solutions. They have a reputation for delivering top-quality results in the manufacturing industry. With their advanced manufacturing capabilities, Precision Machining Pro can produce complex components with tight tolerances, ensuring the highest level of accuracy.

At Precision Machining Pro, they pride themselves on their state-of-the-art CNC machines, which are equipped with advanced technology to meet the most demanding requirements. Their team of expert technicians is highly skilled in operating these machines, ensuring precise and efficient machining processes.

With a focus on delivering advanced manufacturing solutions, Precision Machining Pro caters to various industries, including automotive, aerospace, and medical devices. They understand the unique needs of each industry and provide tailored CNC machining services to meet their clients’ requirements.

Whether it’s prototyping or large-scale production, Precision Machining Pro offers reliable and efficient CNC machining services. They have the capabilities and expertise to handle projects of any size and complexity, providing their clients with high-quality components that meet their specifications.

Partnering with Precision Machining Pro for your CNC machining needs ensures that you receive the precision and accuracy required for your project’s success. Their commitment to excellence and their advanced manufacturing solutions make them the go-to CNC machining service provider in the industry.

Choosing a CNC Machining Service

When it comes to choosing a CNC machining service, there are several factors you should consider to ensure you make the right decision. The quality and precision of the machining should be at the top of your list. Look for a service provider that has a proven track record of delivering high-quality parts with tight tolerances and complex design requirements. This will ensure that your finished product meets the highest standards of quality and reliability.

Another important factor to consider is the turnaround time offered by the CNC machining service. Timely delivery is crucial to meeting your production timelines and maintaining a smooth workflow. Make sure to choose a service provider that is known for its efficiency and ability to deliver projects on time.

Cost-effectiveness is also a key consideration. While it’s important to find a CNC machining service that fits within your budget, it’s equally important to balance cost with quality. Look for a provider that offers competitive pricing while still delivering exceptional results. Remember, it’s not just about the upfront cost, but also the overall value provided by the service.

Lastly, researching customer reviews and testimonials can provide valuable insights into the reputation and reliability of the CNC machining service. A strong reputation for quality, excellent customer service, and timely delivery is a good indication that you can trust the service provider to meet your needs.

By carefully considering these factors, you can choose a CNC machining service that offers the quality, precision, turnaround time, and cost-effectiveness you require for your project.

Get more information now

Final Thoughts

In conclusion, CNC machining services provide a range of benefits that make them an essential part of the modern manufacturing industry. With their high precision and efficient production capabilities, CNC machines offer unparalleled accuracy and consistency in the creation of complex metal parts.

The advancements in CNC technology have revolutionized the way we manufacture components, allowing for tighter tolerances, intricate designs, and faster turnaround times. CNC machining services are versatile, as they can efficiently work with various materials such as metals, plastics, and wood.

When it comes to CNC machining services, Precision Machining Pro is a trusted provider that offers advanced manufacturing solutions. Their state-of-the-art CNC machines, expert technicians, and advanced software ensure the highest level of quality and accuracy in every project. Whether you need prototyping or large-scale production, Precision Machining Pro can meet your unique needs with precision and efficiency.

In today’s competitive market, CNC machining services play a crucial role in the success of businesses across industries. By leveraging the benefits of CNC machining services, manufacturers can achieve exceptional precision, efficiency, and versatility in their production processes, ultimately gaining a competitive edge in the market.

FAQ

What are CNC machining services?

CNC machining services utilize computer numerical control to efficiently and accurately produce a wide range of metal parts.

What are the benefits of CNC machining services?

CNC machining services offer high precision, complex design capabilities, and increased productivity.

How does CNC machining work?

CNC machining works by using computer-controlled machines to precisely remove material from a workpiece.

What materials can be used in CNC machining?

CNC machining can be performed on a wide range of materials, including metals, plastics, and woods.

What are some common applications of CNC machining?

CNC machining is commonly used in industries such as automotive, aerospace, and medical devices to manufacture components with tight tolerances and intricate designs.

What are the different techniques used in CNC machining?

CNC machining encompasses techniques such as milling, turning, laser cutting, plasma cutting, and 3D printing.

What is Precision Machining Pro?

Precision Machining Pro is a leading CNC machining service provider that specializes in high precision machining solutions.

What factors should be considered when choosing a CNC machining service?

The quality and precision of the machining, turnaround time, and cost-effectiveness are important factors to consider when choosing a CNC machining service.

What are the main takeaways of CNC machining services?

CNC machining services offer high precision, efficient production, and the ability to work with various materials, making them a valuable solution in today’s manufacturing industry.

More Sources Links

- https://www.americanrotary.com/blog/cnc-machining-for-beginners/

- https://www.cnccookbook.com/learn-cnc-basics-tutorial/

- https://metrom.com/the-abc-of-cnc-machining-a-beginners-guide-to-getting-started/