Unlock Precision & Efficiency

Your CNC Machining Partner for Newcomers and companies looking for obligation-free competitive cost analysis.

Latest News

New to CNC machining

Some of the Specialist Areas of Machining we focus on

We provide exceptional on-demand production services on a global scale.

Our most valuable asset is our rapidly expanding customer base, developed largely through word-of-mouth recommendations worldwide.

This diverse customers ranges from independent inventors and designers to major players in industries such as Industrial, Commercial, Marine, Automotive, and Robotics sectors.

CNC Marine Parts

We machine all types of marine parts including Deck hardware CNC machined for sailing boats typically includes winches, cleats, fairleads, blocks and pulleys, clutches and jammers, deck organizers, travellers and tracks, hinges and latches, bollards and chocks, and custom fittings.

CNC Motorcycle Parts

We machine all types of motorcycle parts including, suspension components (such as fork clamps and shock absorber mounts), chassis parts (like frame sliders and swingarm spools), and custom parts (such as foot pegs, levers, and handlebars). These parts are crucial for the safety, and customization of motorcycles.

CNC Motor Vehicle Parts

We machine all types of motor vehicle parts including, commonly include engine components, gearbox parts, suspension components (such as control arms and struts), and custom aesthetic elements like grilles or trim. These parts are essential for the vehicle's performance, safety, and efficiency. They may be parts for classic or vintage models.

CNC Robotics Parts

We machine all types of Robotics parts including, gears and gear racks, bearing housings, shafts and axles, motor mounts, end effectors (such as grippers and clamps), custom brackets and frames, servo arms and linkages, and heat sinks. These components are integral to the precision, functionality, and structural integrity of robotic systems.

CNC Scooter Parts

We machine all types of Robotics parts including, frame components, motor mounts, battery enclosures, wheel hubs, brake components, steering mechanisms, suspension parts, throttle and brake levers, and kickstands. Additionally, custom decorative elements or structural reinforcements are also commonly produced using CNC machining for enhanced aesthetics and durability.

CNC Electric Motor Parts

We machine all types of Robotics parts including, CNC machined parts for electric motors typically include the motor housing, end caps, rotor, stator, shafts, bearing mounts, cooling fins, and brush holders. These components are essential for the motor's structure, efficiency, thermal management, and overall performance.

Our Values

We know you have many choices for your CNC project. The type of customers we work with are customers who are both price conscious and are able to work together to achieve the best outcome for the project.

Our strength is the ability to communicate with our customers and assist them to reach their goal for any size project.

From small projects to enterprise size orders we treat each inquiry with the urgency required to meet your expectations.

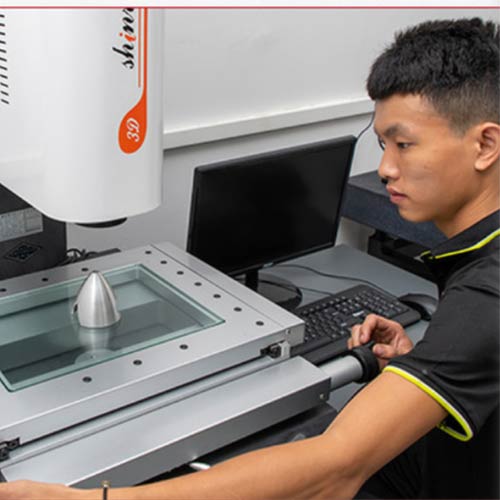

Information about Our Factory

Some photos of our factory and experienced Staff at work

Value on All Projects

New customers can get in touch with our engineering team for a complementary cost analysis and quote on their projects. We will review your specifications, provide advice on design for manufacturability, and give accurate costing based on your production volumes. With a focus on responsiveness and transparency, we aim to be a machining partner you can trust to translate your product visions into reality. Get in touch today to get started on your next machining project!

Some of Our Services

Click on a service and it will open the information about the service

CNC Machining

Precision Machining Pro specializes in the highest experience in precision machining. While numerous CNC machining shops offer a range of CNC machined parts for varying projects, we specialize in CNC precision machining.

Custom CNC

Custom CNC projects usually need to fit with existing parts, they may require very precise CNC machine programming and accuracy. With a higher level of skill needed by the CNC machine operator to machine the parts.

Custom CNC Parts

Ensuring the right fit and esase of use parts from small consumer products to complex robotic parts and equipment, custom-machined components enable products and innovations that shape the modern world.

Custom CNC Services

CNC services, in this section we can give you advice from our expert staff with decades CNC machining experience.

These engineers and sales staff specialize in long term projects or projects above 100 pcs.