Online machining service requires communication efficiency and security for customers.

Precision Machining Pro strives to:

Ensure efficiency and security of our online and offline operation procedures

With ISO 9001 accreditation we learned that this type of system must be expanded beyond the basic requirement.

While ISO 9001 builds the confidence of the customers in a company and reinforces the ability of customers, the company must be able to communicate and measure the assessed quality.

As a precision machining manufacturer, Precision Machining Pro highly values the highest consistency and stability of our quality products. We keep detailed records to be able to measure the quality for purchasing, producing, manufacturing, and shipping. We maintain strict control of data storage and customers’ information and security.

In doing so, Precision Machining Pro puts the efforts into:

Our management of electronic systems

Precision Machining Pro reduced our paperwork and computerized our management. This not only reduced our paper usage, for conservation reasons but it increased our ability to deal with data search.

Reinforcing our information security

We have installed efficient redundancy in our systems for data protection. We ensure we can prevent damage from power failure, or data leaks. We have an Uninterruptible Power System (UPS).

The staff in Precision Machining Pro also have approved authorization levels to be able to access permission to data. This is based on their job levels.

We take steps to synchronize the essential data for backup to the Cloud drive.

Cloud synchronizing our data

To secure our confidential information, we use a globally recognized Cloud service. This means backups of the data in the cloud system, can be restored or accessed quickly on portable devices by people authorized the access the information.

Instant communication

We are at the leading edge of Internet and Mobile communication, to ensure clear communication we still mainly rely on email services to contact our customers and suppliers.

We are implementing secure online systems to be able to digitally communicate drawings and information.

The use of social media systems of communication will gradually take over the rapid deployment of after-sales service requirements in real-time.

We are also using an online quoting system to cut the time required for quick evaluation of products or projects, especially for smaller orders. With the ability to send the complete drawings. We believe the transfer of online drawing will also eliminate the need to digitize the information, therefore, eliminating the possibility of miscommunication.

Key Takeaways:

- Online support systems have transformed the CNC machining industry.

- These systems utilize advanced software and IoT technology for real-time monitoring and analysis.

- MachineMetrics is a leading provider of online support systems, offering improved efficiency, reduced waste, and real-time visibility.

- Utilizing online support systems enables manufacturers to optimize operations and make data-driven decisions.

- Choosing the right online support system is crucial for maximizing productivity and profitability.

At Precision Machining Pro, we understand the importance of streamlined operations and optimized productivity in the CNC machining industry. That’s why we advocate for the utilization of efficient online support systems for CNC machining. These systems have revolutionized the way manufacturers approach technical needs by providing rapid and reliable solutions.

Online support systems leverage advanced software and IoT technology to monitor and analyze real-time production data. This data-driven approach enables manufacturers to make faster, smarter decisions based on actionable insights. One of the leading providers of online support systems is MachineMetrics, which offers a user-friendly platform that seamlessly integrates with any machine type and provides key benefits for manufacturers.

The Benefits of Machine Monitoring Systems

Machine monitoring systems, like the one offered by MachineMetrics, provide invaluable support to manufacturers in the CNC machining industry. These digital systems offer a range of benefits that enhance efficiency and productivity, reduce waste, and optimize overall equipment performance.

Improved Manufacturing Efficiency

By utilizing machine monitoring systems, manufacturers gain real-time insights into their production processes. This allows them to identify bottlenecks, streamline workflows, and optimize machine utilization. With access to accurate and up-to-date data, companies can minimize downtime, increase throughput, and achieve higher levels of efficiency.

Reduced Production Waste for Increased Profits

Nobody likes waste, especially when it affects the bottom line. Machine monitoring systems enable manufacturers to identify and address production inefficiencies, helping to minimize scrap and reduce material waste. By monitoring key metrics in real-time, such as tool wear and energy consumption, companies can proactively take corrective actions to optimize production and boost profitability.

Real-Time Shop Floor Visibility

With digital support systems for CNC machining, manufacturers gain real-time visibility into their shop floor operations. Machine monitoring systems provide a comprehensive overview of machine status, production progress, and operational performance. This real-time visibility empowers companies to make informed decisions, implement timely adjustments, and maintain efficient production schedules.

Shop-Floor Alerts and Notifications

Machine monitoring systems offer shop-floor alerts and notifications to keep manufacturers informed about important events and milestones in the production process. These alerts can include machine performance issues, quality deviations, maintenance requirements, and more. With timely notifications, operators and managers can take immediate action to address issues and minimize disruptions.

Improved Operator Engagement and Overall Company Communication

Machine monitoring systems facilitate enhanced operator engagement and communication within the manufacturing environment. With real-time visibility and access to performance data, operators can actively contribute to process improvement initiatives and collaborate with colleagues to identify and solve production challenges. This improved communication fosters a culture of continuous improvement and empowers operators to maximize their impact on the manufacturing process.

Automated Data Collection and Analytics

By automating data collection and analysis, machine monitoring systems eliminate the need for manual data entry and paper-based records. This not only saves time and reduces errors but also enables companies to generate accurate and reliable reports on key performance indicators. With advanced analytics capabilities, manufacturers can uncover actionable insights, identify trends, and make data-driven decisions to optimize their operations.

Custom Reporting

Machine monitoring systems often provide customizable reporting options to meet specific business needs. Manufacturers can define the metrics they want to track, set thresholds for alerts and notifications, and generate tailored reports for different stakeholders. This flexibility in reporting empowers manufacturers to focus on the data points that matter most and gain deeper insights into their production processes.

Increased Overall Equipment Efficiency

Machine monitoring systems contribute significantly to overall equipment efficiency (OEE), a key metric in the manufacturing industry. By providing real-time insights into production performance, these systems help manufacturers measure and improve the availability, performance, and quality of their equipment. By leveraging the power of data-driven insights, manufacturers can optimize their machines’ utilization and make proactive decisions for continuous improvement.

| Benefits of Machine Monitoring Systems |

|---|

| Improved manufacturing efficiency |

| Reduced production waste for increased profits |

| Real-time shop floor visibility |

| Shop-floor alerts and notifications |

| Improved operator engagement and overall company communication |

| Automated data collection and analytics |

| Custom reporting |

| Increased overall equipment efficiency |

How Machine Monitoring Systems Work

Machine monitoring systems play a crucial role in the optimization of CNC machining operations. These systems collect data from each machine control and machine operator on the production floor, providing manufacturers with valuable insights for improving efficiency and productivity. Let’s take a closer look at how these systems work and their key functionalities.

Firstly, data collected from CNC machines and operators is securely stored in the cloud. This ensures accessibility from anywhere, allowing manufacturers to monitor their operations in real-time. To access this data, a mobile-friendly application is used, providing convenience and flexibility for monitoring and analysis.

One of the primary features of machine monitoring systems is the use of real-time dashboards. These intuitive dashboards present visualizations of important production metrics, enabling manufacturers to quickly assess the performance of ongoing jobs. By monitoring these metrics, manufacturers can identify if jobs are performing at or below expectations, and take immediate action to address any issues that may arise.

Beyond job performance, machine monitoring systems also monitor machine conditions, production status, quality tracking, and downtime reasons. This comprehensive monitoring ensures that manufacturers have a complete view of their operations and can identify potential bottlenecks or inefficiencies.

Additionally, advanced reporting features allow for in-depth analysis of various parameters such as Overall Equipment Efficiency (OEE), job performance, downtime, and quality. By analyzing these metrics, manufacturers can identify areas for improvement, implement targeted process improvements, and measure the impact of these changes on overall efficiency.

Benefits of Machine Monitoring Systems:

- Improved efficiency through real-time monitoring and analysis

- Identification of production bottlenecks and areas for improvement

- Enhanced visibility into machine conditions and status

- Streamlined quality tracking and analysis

- Reduced downtime through proactive maintenance and troubleshooting

By leveraging machine monitoring systems, manufacturers can optimize their CNC machining operations, reduce production costs, and ultimately achieve higher levels of productivity. These systems provide the necessary support for efficient troubleshooting, maintenance, and continuous improvement.

Comparison of Features and Benefits of Top Machine Monitoring Systems

| Machine Monitoring Systems | Features | Benefits |

|---|---|---|

| MachineMetrics | – Real-time dashboards – Advanced reporting and analytics – Remote monitoring capabilities | – Improved production efficiency – Enhanced decision-making – Reduced downtime |

| Predictronics | – AI-powered predictive analytics – Anomaly detection – Health monitoring | – Predictive maintenance – Early detection of machine malfunctions – Increased equipment lifespan |

| Scytec DataXchange | – Real-time machine monitoring – OEE tracking and analysis – Shop floor visualization | – Improved productivity – Enhanced operator visibility – Data-driven decision-making |

As shown in the table above, machine monitoring systems offer unique features and benefits that cater to different manufacturing needs and requirements. Manufacturers need to assess these options and choose the system that aligns with their specific goals and objectives.

The Rise of Online CNC Services

The manufacturing industry has been transformed by the rise of online CNC services. These services leverage computer numerical control (CNC) technology to automate machining processes and deliver precise and accurate parts. What sets online CNC services apart is their accessibility and range of features, making CNC machining services more readily available to businesses of all sizes and industries.

These online platforms provide a host of benefits for manufacturers, including instant quotation systems, comprehensive material selection, and advanced machining capabilities. With just a few clicks, manufacturers can receive accurate cost estimates and select from a wide range of materials for their CNC projects. This streamlined process saves time and enables faster decision-making, facilitating efficient production planning.

Online CNC services have also democratized manufacturing by breaking down barriers to entry. Previously, only larger businesses could afford CNC machining services due to high costs and limited availability. However, with the advent of online platforms, smaller businesses and startups now have access to affordable CNC services. This leveling of the playing field has sparked innovation and competition, driving industry growth.

The Advantages of Online CNC Services

Online CNC services offer a wide range of advantages for manufacturers:

- Cost-effectiveness: Online platforms provide cost transparency, allowing manufacturers to compare prices from multiple service providers and choose the most cost-effective option for their projects.

- Flexibility: The ability to access CNC services online provides flexibility in terms of location and time. Manufacturers can submit their designs and specifications remotely, eliminating the need for physical visits to machining facilities.

- Quality assurance: Reputable online CNC services ensure high-quality machining results. They maintain stringent quality control measures, use state-of-the-art equipment, and employ skilled machinists to deliver precise and accurate parts.

- Technical support: Online CNC services often provide technical support, troubleshooting guidance, and expert advice. This ensures that manufacturers can overcome any challenges in the CNC machining process with the help of experienced professionals.

With these advantages, manufacturers can leverage online CNC services to enhance their production capabilities, reduce costs, and achieve greater efficiency.

How to Choose the Best Online CNC Service

When it comes to selecting the optimal online CNC service for your manufacturing needs, it’s crucial to consider various factors that will contribute to the success of your operations. At Precision Machining Pro, we understand the importance of finding a service that aligns with your specific requirements and goals. Here are some key considerations to help you in the decision-making process:

- User Interface: Evaluate the user interface of different online CNC services to ensure it is intuitive and user-friendly. A well-designed interface will streamline your experience and make it easier to navigate through the platform.

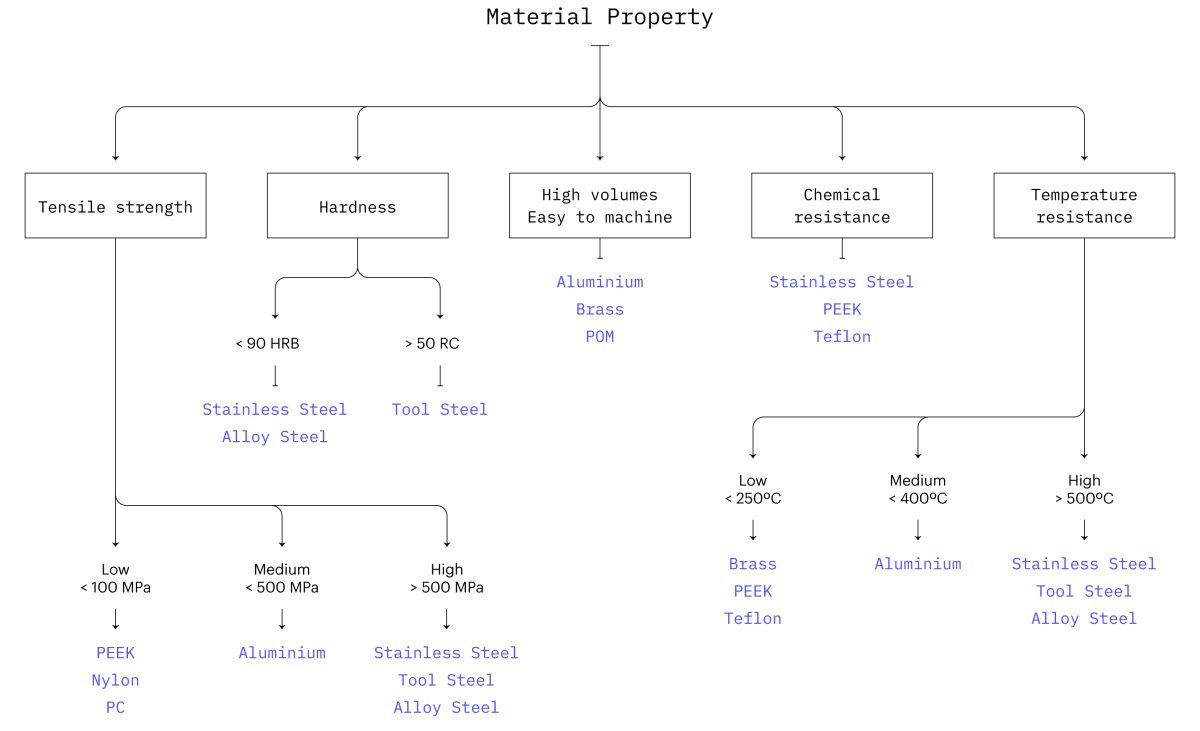

- Material Selection: Look for a service that offers a wide range of materials to choose from. This will enable you to select the most suitable materials for your manufacturing projects.

- Quotation System: Assess the quotation system provided by each service. Look for platforms that offer instant quotations, allowing you to quickly estimate the cost of your projects.

- Machining Capabilities: Consider the machining capabilities offered by different services. Look for comprehensive machining options that can meet your specific requirements, such as precision, speed, and complexity.

- Quality Assurance Protocols: Ensure that the online CNC service has robust quality assurance protocols in place. This will help ensure that your parts meet the required quality standards.

- Pricing: Compare the pricing structures of different services to find one that fits within your budget while still offering the desired level of quality.

Additionally, it’s important to take into account any specific requirements or preferences you may have. Consider whether you need specialized support, software tools, or assistance with troubleshooting and maintenance. By carefully evaluating and comparing the features and benefits of different online CNC services, you can make an informed decision and find a service that best suits your needs.

Choosing the Right Assistance and Software Solutions

At Precision Machining Pro, we pride ourselves on providing exceptional CNC machining assistance and software solutions to manufacturers in the industry. Our team of experts is committed to offering comprehensive support and guidance throughout the manufacturing process. With our advanced software solutions, you can optimize your operations, improve efficiency, and streamline your workflow for enhanced productivity.

Final Thoughts

Online support systems for CNC machining have revolutionized the industry by providing efficient and reliable solutions for technical needs. These systems offer numerous benefits, including improved efficiency, reduced waste, real-time visibility, and automated data collection. By leveraging the power of machine monitoring systems and online CNC services, manufacturers can optimize their operations, make data-driven decisions, and stay ahead of the competition in an increasingly competitive landscape.

Choosing the right online CNC service is crucial for manufacturers. It is important to carefully evaluate the options and find a service that meets specific requirements and goals. With the right support system in place, manufacturers can maximize productivity, improve quality, and drive profitability in the CNC machining industry.

At Precision Machining Pro, we are dedicated to helping manufacturers navigate the world of online support systems and find the best solutions for their CNC machining needs. Our team of experts is committed to providing unparalleled support and guidance throughout the decision-making process. With our assistance, manufacturers can confidently choose an online CNC service that aligns with their goals and unlocks their true potential.

FAQ

What are the benefits of online support systems for CNC machining?

Online support systems for CNC machining offer improved efficiency, reduced waste, real-time visibility, and automated data collection.

How do machine monitoring systems work?

Machine monitoring systems utilize advanced software and IoT technology to collect real-time data from CNC machines and provide insights for improved decision-making.

What are online CNC services?

Online CNC services are platforms that offer automated machining processes, comprehensive material selection, and instant quotation systems for businesses of all sizes and industries.

Which are the top online CNC services?

Some of the top online CNC services include ProleanTech, Xometry, 3D Hubs, Protolabs, and Fictiv, each offering unique features and strengths.

How should I choose the best online CNC service?

When choosing an online CNC service, consider factors such as user interface, material selection, quotation system, machining capabilities, quality assurance protocols, and pricing, based on your specific requirements and preferences.