The manufacturing of marine parts requires precision and accuracy to ensure optimal performance under harsh marine conditions. Precision turning, utilizing CNC machining techniques, plays a crucial role in delivering high-quality marine components that meet the demanding requirements of the marine industry.

Through precision turning, marine parts manufacturers can create precise and accurate components using materials like stainless steel and brass. This article will explore the benefits of precision turning in marine parts manufacturing and its impact on the marine industry.

Key Takeaways:

- Precision turning is essential for manufacturing high-quality marine parts.

- CNC machining techniques, such as CNC turning, ensure precise dimensions and tight tolerances.

- Precision turning enables the creation of complex designs and use of various materials.

- Marine parts manufactured with precision turning offer durability and reliability.

- Precision turning plays a vital role in the production of propellers, motor components, and molds for prototypes.

The Importance of Precision Turning in Marine Parts Manufacturing

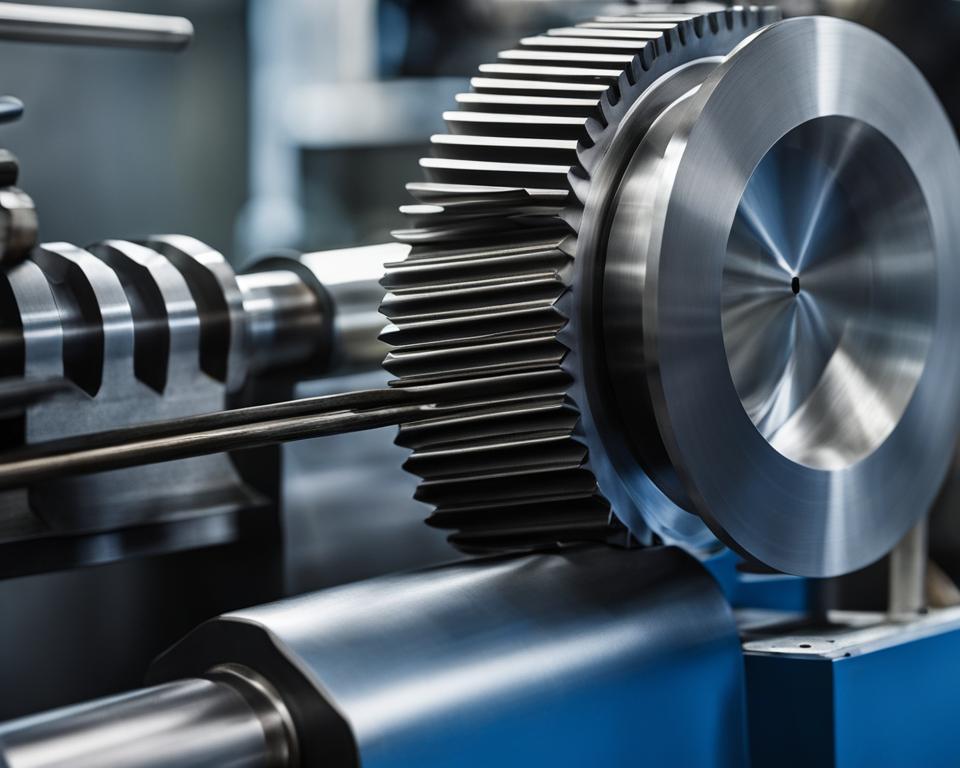

Precision turning is a critical process in marine parts manufacturing that ensures the production of high-quality components for the marine industry. Utilizing CNC machining techniques, such as CNC turning, precision turning allows for the creation of marine parts with precise dimensions and tight tolerances. This level of precision is essential for the proper functioning of marine components in challenging marine environments. Whether it’s propellers, motor components, or molds for prototypes, precision turning plays a crucial role in maintaining the operational efficiency and safety of marine vessels.

With precision turning, marine parts manufacturers can achieve the necessary accuracy and reliability required for marine components. The use of CNC machining techniques enables the creation of complex designs and intricate features that are vital for marine applications. By utilizing materials like stainless steel and brass, precision turning ensures the production of marine parts that offer strength, durability, and resistance to the harsh marine environment. The precision engineering involved in precision turning guarantees the highest level of quality and reliability in marine parts manufacturing.

By leveraging precision turning in marine parts manufacturing, manufacturers can meet the stringent requirements of the marine industry. The precision and accuracy achieved through precision turning allow for seamless integration and assembly of marine components, ensuring optimal functionality. Furthermore, precision turning enables marine parts manufacturers to optimize material usage, reducing waste and minimizing costs. The ability to produce marine parts with faster production times and shorter lead times also allows manufacturers to respond quickly to customer demands and stay competitive in the market.

Advantages of Precision Turning in Marine Parts Manufacturing

Precision turning offers several advantages in marine parts manufacturing. First and foremost, it ensures the production of parts with accurate dimensions, allowing for seamless integration and assembly. Precision turning also enables the creation of complex designs and intricate features that are essential for marine components. Additionally, precision turning allows for the use of various materials, such as stainless steel and brass, that provide strength, durability, and resistance to marine environments. The precision engineering involved in precision turning guarantees the highest level of quality and reliability in marine parts manufacturing.

One of the key benefits of precision turning is its ability to achieve tight tolerances. With CNC machining techniques, precision turning can produce marine parts with precise dimensions and tight tolerances, ensuring the proper functioning of components in challenging marine environments. This level of precision is crucial in industries such as shipbuilding, offshore drilling, and marine transportation, where safety and performance are paramount.

Precision turning also offers flexibility in manufacturing. It allows for the production of different types of marine parts, such as propellers, motor components, and molds for prototypes. The versatility of precision turning ensures that manufacturers can meet the diverse needs of the marine industry. It enables them to create custom-designed components that fit specific requirements and can withstand the harsh conditions encountered at sea.

The benefits of precision turning in marine parts manufacturing can be summarized as follows:

- Accurate dimensions for seamless integration and assembly

- Creation of complex designs and intricate features

- Use of materials with strength, durability, and resistance to marine environments

- Achievement of tight tolerances for optimal functionality

- Flexibility in manufacturing to meet diverse industry needs

Overall, precision turning plays a crucial role in marine parts manufacturing by providing the necessary precision, reliability, and quality for the production of components that can withstand the demanding marine environment. Its advantages in terms of accurate dimensions, complex designs, material versatility, and tight tolerances make it an indispensable process for the marine industry.

CNC Machining in Marine Parts Manufacturing

CNC machining is a fundamental process in marine parts manufacturing, offering precise and efficient production capabilities. Utilizing computer software and connected manufacturing systems, CNC machines are able to create complex functional parts with high accuracy and precision. In the marine industry, CNC turning is particularly crucial for the production of cylindrical components, such as propellers and motor parts, with tight tolerances and smooth finishes.

One of the key advantages of CNC machining in marine parts manufacturing is its ability to ensure consistent quality and dimensional accuracy. With the use of advanced cutting tools and software, CNC machines can produce marine parts with precise dimensions, allowing for seamless integration and assembly. This level of precision is vital for the proper functioning of marine components in demanding marine environments.

CNC machining also offers enhanced productivity and efficiency in marine parts manufacturing. The automation and advanced capabilities of CNC machines enable faster production times and shorter lead times, allowing marine parts manufacturers to meet customer demands and market trends more effectively. Additionally, CNC machining allows for optimization of material usage, reducing waste and minimizing costs for manufacturers.

“CNC machining is revolutionizing the marine parts manufacturing industry, providing manufacturers with the tools to create high-quality components with speed and precision.”

The Advantages of CNC Machining in Marine Parts Manufacturing:

- Precise and accurate production of marine components

- Consistent quality and dimensional accuracy

- Ability to create complex functional parts

- Shorter lead times and faster production times

- Optimization of material usage and cost reduction

| Advantages | CNC Machining | Traditional Machining |

|---|---|---|

| Precision and Accuracy | ✓ | ✗ |

| Complexity | ✓ | ✗ |

| Production Time | Shorter | Longer |

| Material Usage | Optimized | Less optimized |

| Cost Efficiency | ✓ | ✗ |

As CNC machining continues to advance, it holds great potential for the future of marine parts manufacturing. The integration of new technologies, such as 5-axis machining and additive manufacturing, further expands the capabilities of CNC machining and opens up new possibilities in the production of marine components. By embracing CNC machining in marine parts manufacturing, manufacturers can unlock greater efficiency, precision, and quality in their operations, ultimately enhancing the performance and reliability of marine vessels.

Applications of Precision Turning in the Marine Industry

Precision turning plays a crucial role in the marine industry, with a wide range of applications in the manufacturing of various marine components. From propellers to motor parts, precision turning ensures the production of high-quality components that meet the stringent requirements of the marine industry. Let’s explore some of the key applications of precision turning in the marine industry.

Table: Applications of Precision Turning in the Marine Industry

| Application | Description |

|---|---|

| Propellers | Precision turning is used to manufacture propellers with accurate dimensions and tight tolerances. This ensures optimal performance and efficiency of marine vessels. |

| Motor Parts | From engine components to transmission gears, precision turning is employed to create intricate motor parts that are essential for the functioning of marine vessels. |

| Insulating Cases | Precision turning is utilized in the production of insulating cases that protect sensitive electrical components from the corrosive marine environment. |

| Molds for Prototypes | Precision turning is used to create molds for prototypes in the marine industry. These molds allow for the testing and validation of new designs before mass production. |

These are just a few examples of how precision turning is applied in the marine industry. Whether it’s for commercial ships, defense vessels, or offshore rigs, precision turning plays a vital role in ensuring the production of high-quality marine components that meet the industry’s demands for durability, reliability, and optimal functionality.

The Role of Digital Manufacturing in Marine Parts Manufacturing

Digital manufacturing is revolutionizing the marine parts manufacturing industry. It offers faster and low-volume sourcing options for products and parts in the marine industry. With advancements in technologies such as 3D printing, CNC machining, and injection molding, digital manufacturing enables the production of high-quality marine parts with shorter lead times and greater flexibility.

One of the key advantages of digital manufacturing in marine parts manufacturing is the ability to rapidly prototype designs. By utilizing 3D printing and CNC machining, manufacturers can quickly create physical prototypes of marine components, allowing for design optimization and faster product development.

| Advantages of Digital Manufacturing in Marine Parts Manufacturing |

|---|

| 1. Faster prototyping and product development |

| 2. Customization and flexibility in design |

| 3. Reduced lead times for production |

| 4. Improved part performance and functionality |

| 5. Cost-effective production for low-volume orders |

This technology allows for the creation of complex geometries and the customization of components, providing marine parts manufacturers with a competitive edge in meeting the diverse demands of the marine industry. Whether it’s producing intricate propellers or designing molds for prototypes, digital manufacturing offers increased efficiency and agility in marine parts manufacturing.

In summary, digital manufacturing is transforming the marine parts manufacturing landscape with its ability to enhance production processes, reduce lead times, and deliver high-quality marine components. As the marine industry continues to advance, manufacturers must embrace digital manufacturing technologies to stay competitive and meet the evolving needs of the market.

Choosing the Right Manufacturing Partner for Marine Parts Manufacturing

When it comes to marine parts manufacturing, selecting the right manufacturing partner is crucial to ensure the delivery of high-quality components that meet industry standards and requirements. A reliable manufacturing partner possesses the necessary expertise and certification in precision machining, including precision turning, to handle the complex demands of the marine industry.

One important consideration when choosing a manufacturing partner is their capability in CNC turning, CNC milling, and other precision machining processes. These processes are essential in producing marine parts with precise dimensions and tight tolerances, ensuring optimal functionality. Reviewing case studies and customer testimonials can provide valuable insights into the manufacturing partner’s track record and capabilities.

Collaborating with a reputable and experienced manufacturing partner offers multiple advantages. It guarantees access to advanced machining technologies, skilled operators, and efficient production processes. A reliable partner will work closely with you to understand your specific requirements and provide tailored solutions that meet your needs.

Table: Key Factors to Consider When Choosing a Manufacturing Partner

| Factors | Considerations |

|---|---|

| Expertise and Certification | Ensure the manufacturing partner has expertise and relevant certifications in precision machining for the marine industry. |

| Capabilities | Assess the partner’s capabilities in CNC turning, CNC milling, and other precision machining processes required for marine parts manufacturing. |

| Track Record | Review case studies and customer testimonials to gauge the manufacturing partner’s past performance and ability to deliver high-quality marine parts. |

| Collaboration and Communication | Ensure effective collaboration and communication with the manufacturing partner to align expectations and meet project requirements. |

| Quality Assurance | Verify the manufacturing partner’s quality assurance processes and certifications to ensure consistent quality and reliability in the production of marine parts. |

By choosing the right manufacturing partner for your marine parts manufacturing needs, you can establish a long-term partnership that drives excellence, innovation, and success in your operations.

The Future of Precision Turning in Marine Parts Manufacturing

Precision turning in marine parts manufacturing is continuously evolving, driven by advancements in technology and the increasing demand for high-quality marine components. The future looks promising as precision turning embraces new technologies and techniques, revolutionizing the industry and offering exciting possibilities for marine parts manufacturers.

One of the key future technologies that will shape precision turning in marine parts manufacturing is additive manufacturing, commonly known as 3D printing. This technology allows for the production of complex geometries and customized components with faster lead times and reduced costs. By utilizing 3D printing, marine parts manufacturers can efficiently create prototypes, optimize designs, and produce lightweight yet durable parts for marine applications.

Another area of future development in precision turning is the integration of automation and robotics. These technologies enable increased productivity, accuracy, and efficiency in the manufacturing process. Automated precision turning machines can perform intricate tasks with minimal human intervention, ensuring consistent quality, reducing errors, and improving overall output. The use of robotics in precision turning allows for faster production rates, reduced cycle times, and enhanced precision, ensuring that marine parts manufacturers can meet the growing demands of the industry.

“The integration of 3D printing and automation in precision turning opens up new possibilities for marine parts manufacturers. These technologies enable us to create complex designs, optimize production processes, and deliver high-quality components with unmatched precision and efficiency.”

Additionally, advancements in materials and tooling technologies will continue to drive the future of precision turning in marine parts manufacturing. New materials with improved properties, such as enhanced corrosion resistance and greater strength-to-weight ratios, will enable the production of even more durable and efficient marine components. Advanced tooling technologies, such as high-speed machining and multi-axis machining, will further enhance the precision, speed, and productivity of the turning process.

In summary, the future of precision turning in marine parts manufacturing is bright, with the industry poised to benefit from advancements in additive manufacturing, automation, materials, and tooling technologies. By embracing these future technologies, marine parts manufacturers can unlock new levels of excellence, delivering high-quality components that meet the evolving demands of the marine industry.

Advancements in Precision Turning Techniques

Precision turning techniques have undergone significant advancements in recent years, thanks to improved CNC machines, cutting tools, and software. These advancements have enhanced the precision, accuracy, and speed of the turning process, resulting in superior quality marine parts. High-speed machining and multi-axis machining have become more prevalent, allowing manufacturers to achieve greater productivity and efficiency in their operations.

One notable development in precision turning is the integration of automation and robotics. By incorporating these technologies, manufacturers can optimize the manufacturing process, reduce human errors, and increase overall output. Automation enables continuous production and eliminates the need for manual intervention, leading to improved consistency and reduced lead times.

“The advancements in precision turning techniques contribute to the production of high-quality marine parts that meet the strict standards and requirements of the marine industry.”

The use of advanced CNC machines, cutting-edge software, and automation in precision turning also allows for greater flexibility and customization. Manufacturers can easily adapt to changing customer requirements and produce complex parts with precision, ensuring a perfect fit for marine applications. This level of customization provides a competitive advantage for marine parts manufacturers, as they can offer tailored solutions that meet specific industry needs.

Advantages of Advancements in Precision Turning Techniques:

- Improved precision, accuracy, and speed in the turning process.

- Enhanced productivity and efficiency through high-speed and multi-axis machining.

- Reduced human errors and increased overall output through automation and robotics.

- Greater flexibility and customization for tailored marine parts.

In conclusion, the advancements in precision turning techniques have revolutionized the marine parts manufacturing industry. These advancements have paved the way for superior quality marine parts, greater productivity, and increased customization. Manufacturers that embrace these advancements can stay ahead in a competitive market and deliver high-quality marine components that meet the strict standards and requirements of the industry.

Benefits of Precision Turning for Marine Parts Manufacturers

Precision turning offers numerous benefits to marine parts manufacturers, enabling them to deliver high-quality components that meet the stringent requirements of the industry.

Firstly, precision turning ensures high-volume production with consistent quality and accuracy. With CNC machining techniques, manufacturers can create marine parts with precise dimensions and tight tolerances, resulting in seamless integration and optimal functionality.

Furthermore, precision turning allows manufacturers to optimize material usage, reducing waste and minimizing costs. By accurately shaping and machining the parts, precision turning ensures efficient use of materials such as stainless steel and brass, providing strength, durability, and resistance to the harsh marine environment.

Lastly, precision turning offers faster production times and shorter lead times, allowing manufacturers to respond quickly to customer demands and market trends. With the ability to create complex designs and intricate features, precision turning enables manufacturers to stay competitive and deliver high-quality marine parts in a timely manner.

| Benefits of Precision Turning for Marine Parts Manufacturers |

|---|

| High-volume production with consistent quality and accuracy |

| Optimized material usage, reducing waste and costs |

| Faster production times and shorter lead times |

Conclusion

Precision turning is a crucial process in marine parts manufacturing, offering unparalleled quality, reliability, and performance. The utilization of CNC machining, including CNC turning, enables the creation of precise and accurate marine components that seamlessly integrate into marine vessels.

With the advancements in digital manufacturing and future technologies, there are exciting opportunities for the marine industry to enhance its manufacturing processes. Embracing these advancements allows manufacturers to meet the evolving demands of the market and deliver high-quality marine parts.

To unlock excellence in marine parts manufacturing, it is crucial to choose the right manufacturing partner. Look for certifications and expertise in precision machining, such as CNC turning and milling, to ensure the highest level of quality and accuracy in the production of marine components.

By staying updated with the latest advancements in precision turning techniques and incorporating them into manufacturing processes, marine parts manufacturers can optimize material usage, reduce costs, and respond quickly to customer demands. Precision turning is the key to delivering exceptional marine components that meet the stringent requirements of the marine industry.

FAQ

What is precision turning in marine parts manufacturing?

Precision turning is a CNC machining technique used to create marine parts with precise dimensions and tight tolerances, ensuring their functionality and performance in the marine environment.

Why is precision turning important in marine parts manufacturing?

Precision turning is crucial in marine parts manufacturing as it ensures the production of high-quality components that meet the stringent requirements of the marine industry, providing durability, reliability, and optimal functionality.

What are the advantages of precision turning in marine parts manufacturing?

Precision turning offers advantages such as accurate dimensions for seamless integration, the creation of complex designs and intricate features, the use of materials like stainless steel and brass for durability, and the highest level of quality and reliability in marine parts manufacturing.

What is the role of CNC machining in marine parts manufacturing?

CNC machining, including CNC turning, is a fundamental process in marine parts manufacturing as it allows for the production of complex functional parts with high accuracy and precision, ensuring efficient production and consistent quality.

What are the applications of precision turning in the marine industry?

Precision turning is utilized in the production of various marine components, including propellers, motor parts, insulating cases, and molds for prototypes, ensuring the smooth operation and performance of marine vessels.

How does digital manufacturing impact marine parts manufacturing?

Digital manufacturing revolutionizes marine parts manufacturing by offering faster and low-volume sourcing options, enabling the production of high-quality marine parts with shorter lead times, greater flexibility, and the ability to rapidly prototype designs and create complex geometries.

What should I consider when choosing a manufacturing partner for marine parts manufacturing?

When selecting a manufacturing partner, it is essential to consider their certification and expertise in precision machining, capabilities in CNC turning and milling, and their track record of delivering high-quality marine parts that meet industry standards and requirements.

What does the future hold for precision turning in marine parts manufacturing?

With advancements in technology, the future of precision turning in marine parts manufacturing looks promising, offering opportunities for the production of more complex geometries, lighter components, faster turnaround times, and meeting the evolving demands of the marine industry.

What advancements have been made in precision turning techniques?

Significant advancements in precision turning techniques include improved CNC machines, cutting tools, and software, high-speed machining, multi-axis machining, and the integration of automation and robotics, enhancing precision, accuracy, speed, and overall output.

What are the benefits of precision turning for marine parts manufacturers?

Precision turning allows for high-volume production with consistent quality and accuracy, optimized material usage, reduced waste and costs, faster production times, shorter lead times, and the ability to respond quickly to customer demands and market trends.

Source Links

- https://jwmachinecorp.com/affordable-metals-to-consider-for-my-precision-cnc-machining-project/

- https://www.protolabs.com/en-gb/resources/white-papers/digital-manufacturing-revolution-in-marine-defence-and-maritime/

- https://prototool.com/cnc-parts/