Welcome to Precision Machining Pro, your trusted partner for CNC machining brass. As experts in the field, we offer high-quality brass machining services that deliver precise results for a wide range of industries. Brass, known for its excellent machinability, corrosion resistance, and thermal conductivity, is a popular material choice for various applications in automotive, aerospace, and electronics industries.

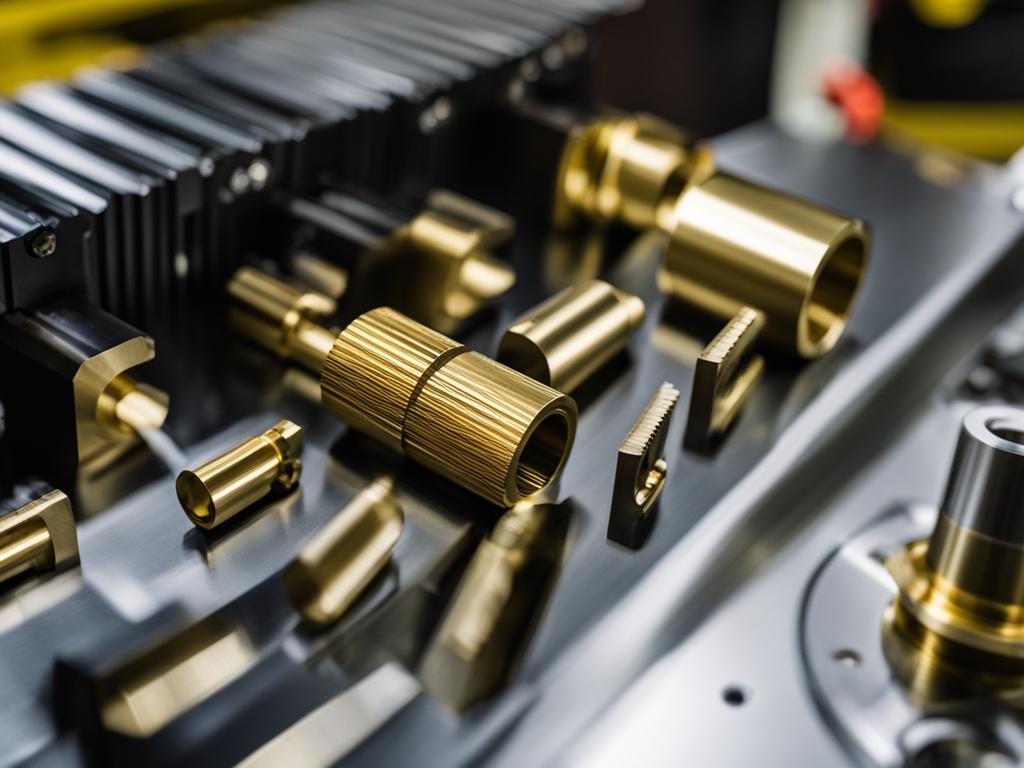

At Precision Machining Pro, we specialize in CNC machining brass, which involves using computer numerical control (CNC) machines to cut, shape, and manipulate brass. This advanced process enables us to create complex and high-performing brass components with exceptional precision.

Key Takeaways:

- Brass is a versatile material with excellent machinability and corrosion resistance.

- CNC machining brass offers precise results and allows for the creation of complex components.

- Precision Machining Pro specializes in delivering high-quality brass machining services.

- Brass components produced through CNC machining are used in various industries.

- Partnering with us ensures efficient production, precise results, and optimal performance of brass components.

The Benefits of CNC Machining Brass

When it comes to precision machining, CNC machining brass offers numerous advantages. Brass, known for its excellent machinability, allows for seamless operations even with complex geometries. This means that intricate designs and precision components can be achieved efficiently and cost-effectively. Whether it’s intricate patterns or tight tolerances, CNC machining brass delivers high-quality results that meet the stringent requirements of different industries.

One of the standout features of brass is its durability and wear resistance. This makes it ideal for applications where components need to withstand mechanical stresses. CNC machined brass parts possess the strength and resilience required to handle demanding conditions, ensuring long-lasting performance and reliability.

In addition to its mechanical properties, brass also offers excellent corrosion resistance. This makes it an ideal choice for applications exposed to moisture or chemicals. CNC machining brass ensures that the corrosion resistance of the material is maximized, resulting in high-quality components that can withstand harsh environments.

At Precision Machining Pro, we specialize in providing high-quality brass machining services. Utilizing state-of-the-art CNC machinery and cutting-edge techniques, our team of experts delivers precise and intricate brass components. From precision CNC milling brass to brass turning services, our capabilities span a wide range of applications. As a trusted brass machining supplier, we are committed to meeting the unique needs of our clients, providing custom brass CNC machining solutions that exceed expectations.

Different Grades of Brass for CNC Machining

When it comes to CNC machining brass, choosing the right grade of brass is crucial to ensure optimal performance and durability of the final component. Various grades of brass are available, each with its own unique composition and properties that make it suitable for specific applications. At Precision Machining Pro, we work with a range of brass grades to meet the diverse needs of our clients.

Commonly Used Brass Grades:

| Brass Grade | Composition | Properties | Applications |

|---|---|---|---|

| C230 | Approximately 85% copper and 15% zinc | Excellent formability, corrosion resistance, and electrical conductivity | Electrical connectors, plumbing fittings |

| C260 | Roughly 70% copper and 30% zinc | Good machinability, high strength, and corrosion resistance | Automotive components, decorative items |

| C272 | About 63% copper and 37% zinc | High ductility, excellent corrosion resistance, and thermal conductivity | Marine fittings, electrical terminals |

| C353 | Approximately 63% copper, 30% zinc, and 2% lead | Improved machinability, high strength, and wear resistance | Gears, valves, fasteners |

| Naval brass | 60-70% copper, 39-40% zinc, and a small amount of tin | Excellent corrosion resistance in seawater, high tensile strength | Marine components, shipbuilding |

At Precision Machining Pro, our experienced team of CNC machining specialists is well-versed in working with different grades of brass. We can guide you in selecting the most suitable grade for your specific application, ensuring that your CNC machined brass components perform optimally and meet the highest quality standards.

Machining Techniques for Brass

CNC machining brass involves a variety of techniques to shape and manipulate this versatile material. These techniques, performed with precision and expertise, ensure accurate and high-quality results. The main machining techniques used for brass include:

Milling

Milling is a process that removes material from the surface of the brass to create a desired shape. It involves rotating cutting tools to cut away excess material, leaving behind a precisely machined component. From intricate patterns to complex shapes, milling allows for the creation of intricate details on brass components.

Drilling

Drilling is a technique used to create holes in brass components. It involves rotating a cutting tool against the surface of the brass to create precise, cylindrical holes of varying diameters. Whether it’s a single hole or a series of holes, drilling ensures accurate placement and sizing for optimal functionality.

Turning

Turning is a technique used to shape the brass by rotating it against a cutting tool. This process involves removing excess material to create cylindrical or tapered shapes. Turning is commonly used to produce components such as shafts, pins, and couplings with high precision and smooth surfaces.

Cutting

Cutting is a technique used to separate the brass into smaller pieces or to remove excess material. It involves using cutting tools to carefully and accurately cut through the brass. Cutting is commonly used when creating multiple components from a larger piece of brass or when removing excess material to achieve the desired shape.

These machining techniques, when applied with expertise and precision, allow for the creation of high-quality brass components. From intricate details to complex shapes, CNC machining brass offers precise and reliable results for various industries and applications.

| Technique | Description |

|---|---|

| Milling | Rotating cutting tools remove material, creating desired shapes and intricate details on brass components. |

| Drilling | Rotating cutting tools create precise holes of varying diameters in brass components. |

| Turning | Rotating the brass against a cutting tool shapes it into cylindrical or tapered forms with high precision. |

| Cutting | Cutting tools are used to separate the brass into smaller pieces or remove excess material to achieve the desired shape. |

Surface Finishes for CNC Machined Brass Parts

After CNC machining brass parts, it is common to apply various surface finishes to enhance their appearance and properties. These finishes not only add aesthetic appeal but also serve functional purposes. Here are some of the most common surface finishes used for CNC machined brass parts:

- Leaving the surface as-machined: This finish preserves the natural appearance of the brass and is suitable for applications where the component’s functionality is the primary focus.

- Brushing: Brushing creates a textured surface that adds visual interest and can help hide any machining marks. It is often used for decorative brass components.

- Polishing: Polishing is a process that produces a smooth and shiny surface. It enhances the reflective properties of the brass, giving it an elegant and luxurious look.

- Bead blasting: Bead blasting is a technique that propels fine glass beads onto the brass surface. It helps remove impurities, create a uniform texture, and prepare the surface for further treatment.

- Coating and plating: Coating or plating the brass with materials like nickel or chrome can enhance corrosion resistance, improve aesthetics, and provide added durability.

The choice of surface finish depends on the specific requirements and desired outcomes for the brass components. Whether you are aiming for a polished, textured, or protective finish, precision machining professionals like us have the expertise to recommend the most suitable surface finish for your CNC machined brass parts.

| Surface Finish | Benefits |

|---|---|

| Leaving the surface as-machined | – Preserves the natural appearance of brass. – Retains the component’s functionality. |

| Brushing | – Creates an aesthetically pleasing texture. – Helps hide machining marks. – Suitable for decorative components. |

| Polishing | – Produces a smooth and shiny surface. – Enhances reflective properties. – Gives an elegant and luxurious look. |

| Bead blasting | – Removes impurities and debris. – Creates a uniform surface texture. – Prepares the surface for further treatment. |

| Coating and plating | – Enhances corrosion resistance. – Improves aesthetics. – Provides added durability. |

Precision and Tolerance in CNC Machining Brass

In the world of CNC machining brass, precision and tolerance are critical factors that determine the quality and functionality of the final components. At Precision Machining Pro, we understand the importance of achieving precise results and maintaining tight tolerances to meet the exact specifications of our clients.

Precision, in the context of CNC machining brass, refers to the accuracy and consistency with which the machining operations are performed. Our skilled operators utilize advanced CNC machines that are equipped with cutting-edge technology, ensuring that each cut, shape, and manipulation of brass is executed with utmost precision. This attention to detail results in components that meet the highest standards of quality and functionality.

Tolerance, on the other hand, refers to the acceptable deviation from the specified dimensions. It allows for minor variations in the size and shape of the brass components, ensuring a seamless fit with other parts in the overall assembly. Our experienced CNC machining specialists work with tight tolerances, meticulously adjusting the machining process to achieve the desired dimensions and ensure the perfect fit of each component.

Why Precision and Tolerance Matter

When it comes to CNC machining brass, precision and tolerance are not mere buzzwords but essential elements that can make or break a project. Achieving precision guarantees that the final components will function as intended, without any flaws or inaccuracies that could compromise their performance. Tight tolerances ensure that the components fit seamlessly with other parts, contributing to the overall reliability and efficiency of the end product.

“”Precision machining of brass components requires expertise, state-of-the-art machinery, and meticulous attention to detail. At Precision Machining Pro, we specialize in delivering precise results that consistently meet or exceed our clients’ expectations.””

Our Commitment to Precision and Tolerance

At Precision Machining Pro, we are committed to upholding the highest standards of precision and tolerance in CNC machining brass. We employ advanced CNC machines and tools that are calibrated regularly to ensure optimal performance and accuracy. Our skilled operators possess the expertise and experience to execute each machining operation with precision, minimizing deviations and producing components with exceptional quality.

We understand that even the slightest deviation from the specified dimensions can have a significant impact on the functionality and compatibility of brass components. That’s why we adhere to strict quality control measures throughout the machining process. Our dedicated quality control team conducts thorough inspections, dimensional checks, and rigorous testing to verify that the components meet the required specifications and tolerances.

Advantages of Precision CNC Machining in Brass

Precision CNC machining in brass offers numerous advantages, including:

- Consistent and accurate results

- Seamless fit with other components

- Optimal functionality and performance

- Enhanced product reliability

- Reduced risk of assembly errors

CNC Machining Services for Custom Brass Components

At Precision Machining Pro, we offer comprehensive CNC machining services for custom brass components. Whether you need a single prototype or a large-scale production run, our team of experts is equipped to meet your specific design requirements. With years of experience in brass fabrication and precision cnc brass machining, we have the knowledge and resources to deliver high-quality custom brass components efficiently and within the required timeframe.

Our custom brass machining services allow for the creation of components tailored to your desired dimensions, tolerances, and functionalities. We understand the importance of precision in CNC machining brass, and our skilled operators utilize advanced machinery to ensure accurate results every time. From milling and drilling to turning and cutting, we employ various machining techniques to shape and manipulate the brass material with meticulous attention to detail.

When you partner with us for custom brass CNC machining, you can expect exceptional quality and performance. Our team meticulously inspects and tests the components at every stage of the machining process to ensure they meet the highest standards. We maintain tight tolerances and thorough quality control measures to deliver reliable and top-notch brass components that exceed your expectations.

At Precision Machining Pro, we understand the importance of your project’s unique requirements. Whether you’re in the automotive, electronics, or any other industry requiring custom brass components, our CNC machining services can cater to your exact needs. We work closely with you to understand your specifications and deliver brass components that enhance the performance, durability, and aesthetics of your final products.

When it comes to custom brass machining, trust Precision Machining Pro for expertise, efficiency, and exceptional results. Contact us today to discuss your project and learn how our CNC machining services can bring your custom brass components to life.

The Importance of Expertise in CNC Machining Brass

CNC machining brass requires specialized expertise and knowledge in working with this specific material. Brass possesses unique properties and necessitates different machining techniques compared to other metals. At Precision Machining Pro, we understand the intricacies of working with brass, and our team of CNC machining specialists possesses extensive experience in the field. With a deep understanding of brass’s characteristics and challenges, our experts can provide valuable insights and recommendations to optimize the machining process, ensuring high quality and avoiding common pitfalls.

Partnering with experts in brass machining is crucial to achieve optimal results and maximize the benefits of CNC machining. Our team’s expertise allows us to deliver precision brass components that adhere to tight tolerances and surpass industry standards. With our unrivaled knowledge and state-of-the-art equipment, we can produce high-quality, custom brass parts that meet your specific requirements.

By working with Precision Machining Pro, you gain access to a team of brass machining specialists committed to delivering exceptional results. We are dedicated to providing top-notch brass machining services, including precision CNC milling, turning, and fabrication, to ensure the highest level of quality and customer satisfaction.

Our team’s expertise combined with our advanced CNC machining capabilities makes us the go-to choice for all your brass machining needs. We have built a solid reputation as a trusted partner in the industry, delivering reliable and efficient services to businesses across various sectors.

Don’t compromise on the quality of your brass components; work with the industry’s experts at Precision Machining Pro. Contact us today to discuss your CNC machining brass requirements and benefit from our unmatched expertise and craftsmanship.

Quality Control in CNC Machining Brass

Quality control is an essential aspect of CNC machining brass. At Precision Machining Pro, we prioritize rigorous inspection and testing throughout the machining process to ensure that our brass components meet the required specifications and maintain high-quality standards.

Our quality control measures encompass multidimensional checks, including dimensional analysis, surface finish verification, material testing, and functional assessment. These comprehensive tests allow us to validate the accuracy, durability, and functionality of our CNC machined brass components.

“Our commitment to quality control is unwavering. We conduct meticulous inspections and assessments at every stage of the manufacturing process to deliver brass components that are not only precise but also reliable and fit for their intended applications.”

Dimensional Checks

Dimensional checks are crucial in CNC machining brass. Our experts utilize advanced measuring equipment to verify the dimensions and tolerances of the machined brass components. This ensures that the finished products align precisely with the intended specifications and guarantee optimal fit and functionality.

Surface Finish Analysis

We understand the importance of impeccable surface finishes in CNC machining brass. Our dedicated team conducts thorough surface finish analysis to assess the aesthetic appeal, texture, and smoothness of our brass components. This attention to detail enhances the overall visual appearance and quality of the final products.

Material Testing

Material testing is a vital part of quality control in CNC machining brass. We employ various testing methods to analyze the composition, integrity, and mechanical properties of the brass materials used in our components. This ensures that our brass components possess the desired strength, corrosion resistance, and durability.

Functional Testing

Functional testing is an essential aspect of quality control for CNC machined brass components. We conduct rigorous tests to evaluate the functionality and performance of our components under real-world conditions. This ensures that our brass components fulfill their intended purpose and meet the performance requirements of diverse industries.

Applications of CNC Machined Brass Components

CNC machined brass components find applications in various industries and sectors. The precision and quality achieved through CNC machining make brass an ideal material for a wide range of applications. From automotive parts to electrical connectors, plumbing fittings to decorative items, the versatility of brass ensures its widespread usage in different industries.

When it comes to automotive parts, CNC machined brass components are used in engine components, fuel injection systems, and braking systems, among others. The durability, corrosion resistance, and high-performance characteristics of brass make it a preferred choice in the automotive industry.

In the electrical industry, brass components are used in electrical connectors, terminals, sockets, and switches. Brass’s excellent electrical conductivity and resistance to heat make it a reliable material for these applications.

Plumbing fittings made from CNC machined brass components ensure leak-free connections and long-lasting performance. The corrosion resistance and machinability of brass make it an ideal material for plumbing applications.

Brass is also commonly used in the production of decorative items due to its aesthetic appeal and ability to be easily molded into intricate designs. CNC machining allows for precise shaping and detailing, creating visually appealing brass decorative pieces.

These are just a few examples of how CNC machined brass components are utilized in various industries. The expertise and precision offered by CNC machining specialists ensure that the brass components meet the specific requirements and enhance the performance and aesthetics of the final products they are used in.

Importance of CNC Machining Services

When it comes to precision machining of brass components, CNC machining services are of paramount importance. At Precision Machining Pro, we understand the critical role these services play in the manufacturing industry. With our expertise, resources, and capabilities, we provide high-quality brass machining services that meet the unique needs of businesses across various sectors.

Utilizing advanced CNC machining processes such as milling, drilling, and turning, our skilled operators ensure the production of precise and intricate brass components. We have extensive experience in working with brass and understand its unique properties, allowing us to optimize the machining process for high-quality results.

As a trusted brass machining supplier, we have a proven track record of delivering excellence. We prioritize efficiency, accuracy, and cost-effectiveness, enabling us to produce complex and precise brass parts. Our custom brass CNC machining services cater to businesses that require tailored components, ensuring that the final products meet the desired specifications and functionalities.

At Precision Machining Pro, we are dedicated to providing the highest quality brass machining services that meet the stringent requirements of our clients. With our expertise in brass fabrication and our commitment to delivering exceptional results, we are the trusted partner for businesses in need of custom brass components.

Why Choose CNC Machining Services for Your Brass Components?

There are several reasons why CNC machining services are essential for brass components:

- High-Quality Results: CNC machining ensures precise and accurate manufacturing of brass components, guaranteeing the highest quality.

- Efficiency: Advanced machinery and skilled operators maximize efficiency, reducing production time and costs.

- Customization: CNC machining services allow for the creation of custom brass components tailored to specific design requirements.

- Expertise: CNC machining suppliers with experience in brass fabrication possess the expertise to optimize the machining process and provide valuable insights.

With our commitment to excellence, Precision Machining Pro offers top-notch CNC machining services that meet the diverse needs of our clients. Whether you require brass milling services, high-quality brass machining, or custom brass CNC machining, we have the capabilities to deliver outstanding results. Partner with us to experience the precision, efficiency, and reliability of our CNC machining services.

| Benefits of CNC Machining Services | Importance of Expertise | Quality Control |

|---|---|---|

| Precision manufacturing for high-quality brass components | Specialized knowledge of working with brass for optimal results | Rigorous inspection and testing to ensure quality standards are met |

| Efficiency and cost-effectiveness in production | Insights and recommendations to optimize the machining process | Dimensional checks, surface finish analysis, material testing, and functional testing |

| Customization to meet specific design requirements | Understanding of brass properties and challenges in machining | Delivering high-quality, reliable brass components |

Conclusion

CNC machining brass offers unparalleled precision and quality, making it the ideal choice for producing high-quality brass components. The unique properties of brass, including its excellent machinability and corrosion resistance, make it a versatile material that finds applications in various industries. When it comes to brass fabrication, partnering with a CNC machining expert is crucial to ensure efficient production and precise results.

With state-of-the-art technology and expertise in brass CNC machining, our machining services provide customized solutions to meet specific design requirements. Whether it’s a small prototype or a large-scale production, our skilled team ensures that each brass component is manufactured with utmost precision, resulting in optimal performance and customer satisfaction.

By collaborating with a reliable brass machining supplier like Precision Machining Pro, businesses can benefit from our cutting-edge equipment and years of experience in the industry. We deliver efficient CNC machining services that adhere to the highest quality standards, ensuring the production of top-notch brass components.

Whether you need brass CNC fabrication, milling services, or a trusted brass machining supplier, our team is here to deliver exceptional results. Contact us today to discuss your brass machining needs and experience the precision and quality that only CNC machining can offer.

FAQ

What is CNC machining brass?

CNC machining brass involves using computer numerical control (CNC) machines to cut, shape, and manipulate brass. This process offers precise results and allows for the creation of complex and high-performing parts.

What are the benefits of CNC machining brass?

CNC machining brass offers excellent machinability, durability, and corrosion resistance. It is cost-effective, efficient, and suitable for applications where precise components are required.

What are the different grades of brass used for CNC machining?

Some commonly used brass grades for CNC machining include C230, C260, C272, C353, and naval brass. Each grade has distinct characteristics and is used in different industries depending on the desired properties of the final component.

What machining techniques are used for CNC machining brass?

CNC machining brass involves techniques such as milling, drilling, turning, and cutting. Each technique is used to shape, remove material, or create holes in the brass.

What surface finishes can be applied to CNC machined brass parts?

Common surface finishes for CNC machined brass parts include leaving the surface as-machined, brushing, polishing, bead blasting, and plating with materials like nickel or chrome.

How important is precision and tolerance in CNC machining brass?

Precision and tight tolerances are crucial in CNC machining brass to ensure accurate and high-quality results. Skilled operators and advanced machinery are required to achieve the desired specifications.

Can CNC machining services provide custom brass components?

Yes, CNC machining services can create custom brass components according to specific design requirements. They offer flexibility and expertise to tailor the dimensions, tolerances, and functionalities of the components.

Why is expertise important in CNC machining brass?

Brass has unique properties and requires specific knowledge and techniques for machining. CNC machining specialists with experience in working with brass can provide valuable insights, recommendations, and optimize the machining process.

What is the importance of quality control in CNC machining brass?

Quality control ensures that the brass components meet the required specifications. This involves rigorous inspection and testing throughout the machining process, including dimensional checks, surface finish analysis, and functional testing.

What are the applications of CNC machined brass components?

CNC machined brass components are used in industries such as automotive, aerospace, electronics, plumbing, and decorative items. They are suitable for applications where durability, corrosion resistance, and precision are essential.

Why are CNC machining services important in the manufacturing industry?

CNC machining services offer the expertise, resources, and capabilities for precision machining. They ensure the production of high-quality brass components through advanced machinery, skilled operators, and cost-effectiveness.

Source Links

- https://www.3erp.com/blog/brass-machining-grades/

- https://at-machining.com/brass-cnc-machining/

- https://proleantech.com/the-definitive-guide-to-brass-machining/