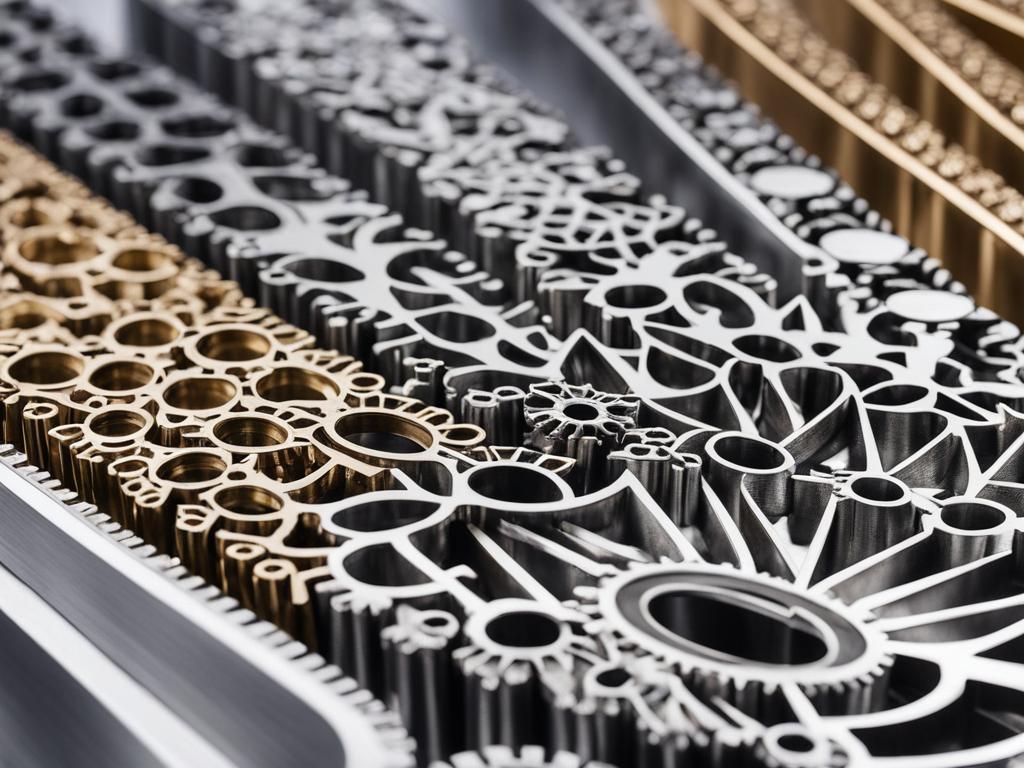

CNC machining has revolutionized the manufacturing industry, allowing for precise and efficient production of parts. However, to achieve the best results, it is essential to choose the right materials for your CNC machining projects. The selection of high-quality and durable materials is crucial for ensuring precision and longevity.

At Precision Machining Pro, we understand the importance of selecting the best CNC machining materials. With our expertise and cutting-edge technology, we offer a wide range of options to meet the unique requirements of your projects.

In this guide, we will explore the factors to consider when selecting CNC machining materials and provide insights into some of the best options available. Whether you are working on a small-scale project or a large-scale production, choosing the right materials is key to achieving the desired results.

Key Takeaways:

- Choosing the right materials is crucial for achieving precise and durable results in CNC machining.

- Evaluate factors such as the end-use, environmental conditions, strength requirements, and budget to select the best materials.

- Common metal materials for CNC machining include aluminum, stainless steel, carbon steel, copper alloys, titanium, and magnesium.

- Plastic materials such as acrylic, polypropylene, acetal, nylon, ABS, UHMW-PE, polycarbonate, and PEEK are also widely used in CNC machining.

- Consider the properties and characteristics of each material to determine the appropriate machining techniques.

Essential Questions for Selecting the Right CNC Material

When it comes to choosing the right material for CNC machining, asking the right questions is crucial. To ensure the best results for your precision machining projects, consider the following essential factors:

- Intended Use: Determine whether the part will be used indoors or outdoors, as this can impact the material’s durability and resistance to environmental factors.

- Stress Load: Consider the amount of stress the part will experience, whether it be mechanical stress, impact resistance, or thermal stress. This will help determine the required strength and resilience of the material.

- Dimensional Tolerance: Evaluate the precision required for your project. Some materials may have better dimensional stability, ensuring accurate and consistent machining.

- Fastening Method: Take into account the method of fastening or joining the part to other components, as this can influence the material’s compatibility and ease of assembly.

- Operating Temperatures: Consider the expected temperature range the part will be subjected to. Some materials excel in high-temperature environments, while others may lose their strength or degrade.

By thoroughly assessing these factors, you can narrow down your options and select the most suitable material for your precision CNC machining project. Precision Machining Pro offers a wide range of advanced materials specifically designed for CNC machining, ensuring high-performance and exceptional quality results.

Quote:

“Choosing the right material for CNC machining is like laying the foundation for a successful project. By considering the specific requirements and evaluating factors such as intended use, stress load, dimensional tolerance, fastening method, and operating temperatures, you can build a solid framework for precision and durability.”

| Material | Advantages | Applications |

|---|---|---|

| Aluminum | Lightweight, high strength-to-weight ratio, excellent thermal and electrical conductivity | Aerospace, automotive, electronics |

| Stainless Steel | Corrosion resistance, high strength, heat resistance | Medical devices, food processing equipment, architectural applications |

| Carbon Steel | Strong, economical, good machinability | Automotive parts, construction equipment, machinery |

| Copper and Its Alloys | Excellent electrical and thermal conductivity, corrosion resistance | Electrical components, plumbing fixtures, heat exchangers |

| Titanium | High strength, low density, exceptional corrosion resistance | Aerospace, medical implants, marine applications |

| Magnesium | Lightweight, good machinability, high strength-to-weight ratio | Aerospace, automotive, sporting goods |

These are just a few examples of advanced materials suitable for precision CNC machining. Depending on the specific requirements of your project, different materials may be recommended. At Precision Machining Pro, we provide expert guidance and a wide selection of high-performance machining materials to meet the demands of your most intricate projects.

Common Metal Materials for CNC Machining

Metal materials are widely used in CNC machining due to their strength and durability. At Precision Machining Pro, we offer a variety of high-quality machining materials that are suitable for a wide range of projects. Here are some common metal materials used in CNC machining:

1. Aluminum

Aluminum is a lightweight metal with excellent machinability. It is commonly used in industries such as aerospace, automotive, and electronics. Aluminum alloys offer good strength-to-weight ratio and corrosion resistance.

2. Stainless Steel

Stainless steel is known for its high strength and corrosion resistance. It is commonly used in applications where durability and aesthetic appeal are important, such as medical devices, kitchen appliances, and architectural components.

3. Carbon Steel

Carbon steel is a versatile material with excellent strength and machinability. It is commonly used in structural components, machinery parts, and automotive applications. Carbon steel is available in different grades to suit specific requirements.

4. Copper and its Alloys

Copper and its alloys, such as brass and bronze, offer excellent conductivity and corrosion resistance. These materials are commonly used in electrical components, plumbing fittings, and decorative applications.

5. Titanium

Titanium is a lightweight and high-strength material commonly used in aerospace and medical industries. It offers excellent corrosion resistance and biocompatibility, making it suitable for implants and surgical instruments.

6. Magnesium

Magnesium is a lightweight material that offers good strength-to-weight ratio. It is commonly used in automotive and aerospace industries, where weight reduction is critical for improving fuel efficiency and performance.

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, good strength-to-weight ratio, corrosion resistant | Aerospace, automotive, electronics |

| Stainless Steel | High strength, corrosion resistant | Medical devices, kitchen appliances, architectural components |

| Carbon Steel | Excellent strength, machinability | Structural components, machinery parts, automotive |

| Copper and its Alloys | Excellent conductivity, corrosion resistant | Electrical components, plumbing fittings, decorative applications |

| Titanium | Lightweight, high strength, corrosion resistant | Aerospace, medical |

| Magnesium | Lightweight, good strength-to-weight ratio | Automotive, aerospace |

These are just a few examples of the common metal materials used in CNC machining. Each material has its own unique properties and applications. By selecting the right material for your project, you can ensure high-quality and durable machining results.

Types of Plastic Materials for CNC Machining

Plastic materials are widely used in CNC machining due to their versatility and excellent machinability. They offer unique properties that make them suitable for a variety of applications. At Precision Machining Pro, we provide a range of plastic materials that are compatible with CNC machining processes. Let’s explore some of the commonly used plastic materials:

| Plastic Material | Advantages | Applications |

|---|---|---|

| Acrylic | Easy machinability, optical clarity, impact resistance | Displays, signage, lighting fixtures |

| Polypropylene | Chemical resistance, high strength-to-weight ratio | Medical devices, automotive components, packaging |

| Acetal | Low friction, excellent dimensional stability | Gears, bearings, conveyor components |

| Nylon | High impact and wear resistance, good tensile strength | Gears, bushings, structural components |

| ABS | Good impact resistance, ease of post-processing | Prototypes, consumer products, automotive parts |

| UHMW-PE | Excellent abrasion resistance, self-lubricating properties | Conveyor components, wear strips, bushings |

| Polycarbonate | High toughness, optical clarity, flame resistance | Eyewear, machine guards, electrical enclosures |

| PEEK | High temperature resistance, excellent mechanical properties | Aerospace components, medical implants, oil and gas applications |

Plastic machining materials provide numerous advantages, including impact resistance, chemical resistance, dimensional stability, and ease of machining. They are commonly used in industries such as electronics, automotive, and consumer goods. With the right plastic material, you can achieve precise and durable results for your CNC machining projects.

Whether you need acrylic for displays, nylon for gears, or PEEK for high-temperature applications, Precision Machining Pro has the expertise and materials to meet your CNC machining needs. Contact us today to discuss your project requirements and discover the best plastic material for your CNC machining project.

Factors for CNC Machining Materials Selection

When it comes to selecting the right materials for CNC machining, there are several crucial factors that need to be considered. By evaluating these factors, you can make an informed decision and choose the best materials for your specific project.

End-Use Requirements

The first factor to consider is the end-use of the part. Determine the specific requirements and performance expectations of the part to ensure that the chosen material can meet those needs.

Environmental Conditions

Take into account the environmental conditions that the part will be exposed to, such as temperature, humidity, and exposure to chemicals or corrosive substances. This will help you choose a material that can withstand these conditions without degradation.

Strength and Dimensional Tolerance

Consider the required strength and dimensional tolerance of the part. Different materials have varying levels of strength and dimensional stability, so choose a material that can meet the desired specifications.

Fastening Method

Understand the type of fastening method that will be used for the part. Some materials may be more suitable for screws, while others may require adhesives or welding. Consider the compatibility of the material with the chosen fastening method.

Operating Temperatures

Evaluate the expected operating temperatures of the part. Some materials may have temperature limitations, either in terms of heat resistance or low-temperature impact toughness. Choose a material that can perform well within the anticipated temperature range.

Weight and Stress Capacity

Assess the weight and stress capacity requirements of the part. Depending on the application, you may need a material that is lightweight yet strong enough to withstand the required loads.

Overall Project Costs

Consider the overall project costs, including material costs, machining expenses, and any additional post-processing steps. Finding a balance between quality and affordability is crucial when selecting CNC machining materials.

By carefully evaluating these factors, you can choose top-notch CNC machining materials that offer a blend of affordability, reliability, and cutting-edge performance. Achieve exceptional results by selecting materials that align with your project’s specific needs.

Tips for Machining Different Materials with CNC Processes

When it comes to CNC machining, different materials require different approaches. To ensure precision and avoid damage to the material, it is essential to use appropriate cutting tools and speeds for metal materials. Meanwhile, plastic materials require careful management of heat buildup and proper cutting techniques. Understanding the unique properties and characteristics of each material is key to achieving optimal results with CNC processes.

For metal materials, use cutting tools specifically designed for metal machining. High-speed steel (HSS) and carbide tools are commonly used for machining stainless steel, aluminum, and other metals. These tools are known for their durability and ability to withstand the heat generated during the machining process. Adjusting cutting speeds and feeds based on the specific material and part design helps achieve the desired precision and surface finish.

On the other hand, machining plastic materials requires attention to heat management. The high heat generated during the machining of plastics can cause melting, burrs, and poor surface finish. To avoid these issues, consider using tools with specialized coatings, such as diamond-like carbon (DLC) or polycrystalline diamond (PCD), which provide low-friction machining and reduce heat buildup. Implementing proper cutting techniques, such as using sharp tools, lower spindle speeds, and light cutting forces, helps ensure clean cuts and prevent excessive heat.

Choosing the Right Tools and Techniques for Precision CNC Machining

When machining metal materials, use cutting tools specifically designed for metal machining, such as high-speed steel (HSS) or carbide tools. These durable tools can withstand the heat generated during machining, ensuring precise results.

To prevent heat-related issues when machining plastic materials, consider tools with specialized coatings like diamond-like carbon (DLC) or polycrystalline diamond (PCD). Applying proper cutting techniques, including using sharp tools, lower spindle speeds, and light cutting forces, helps achieve clean cuts and reduce heat buildup.

Regardless of the material, it is crucial to carefully select the appropriate cutting parameters for CNC machining. This includes optimizing cutting speeds, feeds, and depths of cut to achieve the desired precision and efficient material removal. Working with experienced CNC machinists who are knowledgeable about different materials and machining techniques can significantly contribute to the success of your project.

By leveraging our expertise and state-of-the-art CNC machining capabilities at Precision Machining Pro, we can guide you in selecting the best machining materials and techniques for your specific project. Trust us to deliver the precision and quality you expect. Contact us today to learn more about our CNC machining services.

Choosing the Right CNC Machining Material for Your Projects

When it comes to CNC machining, selecting the right material is paramount to the success of your project. The choice of material can significantly impact the precision, durability, and overall quality of the parts produced.

At Precision Machining Pro, we understand the importance of using the best CNC machining materials for your specific requirements. Our team of experts is here to guide you through the material selection process, ensuring you choose the most suitable option for your project.

When considering CNC machining materials, it is essential to evaluate the properties and capabilities of different options. Factors like strength, hardness, heat resistance, and corrosion resistance must be taken into account. We offer a wide range of materials, from metals to plastics, each with its unique set of benefits and applications.

Here are some key factors to consider when choosing CNC machining materials:

- Material properties: Assess the mechanical, thermal, and chemical properties of the materials under consideration. This will help determine if they meet the specific performance requirements of your project.

- Application: Consider the intended use and environment in which the parts will be utilized. Will they be exposed to extreme temperatures, moisture, or heavy loads? This information will help narrow down the suitable materials.

- Cost: Evaluate the cost-effectiveness of each material option. While high-quality materials may offer superior performance, they may also come at a higher price point. Finding the right balance between quality and cost is essential.

By taking these factors into account, you can make an informed decision and select the best CNC machining material for your projects. Our team is here to provide expert advice and recommend the most advanced and high-quality materials that align with your specific needs and budget.

Selecting the Best CNC Machining Materials

“Choosing the right CNC machining material is crucial for achieving superior results. The advanced materials we offer at Precision Machining Pro have been carefully selected to meet the highest industry standards. With our comprehensive range of options, we can help you find the best material for your project.”

Our commitment to providing high-quality CNC machining materials extends beyond just the materials themselves. We also ensure that our manufacturing processes are precise and efficient, resulting in parts that meet your specifications with exceptional accuracy.

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, excellent conductivity | Aerospace, automotive, electronics |

| Stainless Steel | High strength, excellent corrosion and heat resistance | Medical, marine, food processing |

| Delrin | Low friction, high stiffness, excellent dimensional stability | Automotive, consumer goods, electronics |

| PEEK | High heat resistance, chemical resistance, low moisture absorption | Medical, aerospace, oil and gas |

Our extensive selection of CNC machining materials ensures that we can meet the requirements of a wide range of industries and applications. Whether you need high-performance metals or precision-engineered plastics, we have the materials to deliver exceptional results.

Contact us at Precision Machining Pro today to discuss your project requirements and take advantage of our expertise in choosing the right CNC machining materials. Our dedicated team is ready to assist you throughout the material selection process, ensuring that your project is a success.

Conclusion

CNC machining offers a wide range of materials that can meet the diverse needs of different projects. When selecting the best CNC machining materials, it is crucial to consider factors such as the end-use, environmental conditions, strength requirements, and budget. By carefully evaluating these factors, you can choose the materials that will result in precise, durable, and high-quality outcomes.

At Precision Machining Pro, we understand the importance of selecting the right materials for your CNC machining projects. Our expertise and cutting-edge technology allow us to offer top-quality materials that meet the highest standards of precision and durability. With our wide range of CNC machining materials, you can find the perfect options for your specific application.

Whether you need precision CNC machining materials, top cnc machining materials, or materials that deliver exceptional performance, our team is here to assist you. Contact us today to learn more about our comprehensive CNC machining services and how we can help you achieve optimal results for your projects.

| CNC Machining Materials | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, excellent thermal and electrical conductivity | Aerospace, automotive, consumer electronics |

| Stainless Steel | High strength, corrosion-resistant, heat-resistant | Medical devices, food processing equipment, architectural components |

| Carbon Steel | Durable, strong, good machinability | Automotive components, machinery parts, construction |

| Acrylic | Transparent, lightweight, impact-resistant | Signage, displays, lighting fixtures |

| Nylon | High tensile strength, wear-resistant, low friction coefficient | Gears, bearings, electrical connectors |

About Precision Machining Pro

Precision Machining Pro is your trusted provider of high-quality CNC machining materials. With our cutting-edge technology and expertise, we offer a wide range of materials that meet the highest standards of precision and durability.

As leaders in the industry, we understand the importance of using the right materials for your CNC machining projects. Whether you need metals like aluminum, stainless steel, or titanium, or plastic materials such as acrylic or polycarbonate, we have you covered.

| Why Choose Precision Machining Pro? | Our Services |

|---|---|

|

|

At Precision Machining Pro, we prioritize customer satisfaction and strive to exceed your expectations. Our team of experts is ready to assist you with your CNC machining projects, providing guidance and recommendations based on your specific requirements.

Contact us today to learn more about our CNC machining services and how we can help you achieve exceptional results with our high-quality and cutting-edge materials.

Get the Right CNC Machining Materials for Your Projects

Choosing the right CNC machining materials is essential for achieving the desired precision and durability in your projects. At Precision Machining Pro, we understand the importance of selecting high-quality CNC machining materials that will meet your specific requirements.

Our extensive range of durable CNC machining materials includes metals such as aluminum, stainless steel, and titanium, as well as plastics like acrylic, polycarbonate, and ABS. We carefully evaluate the properties and capabilities of each material to ensure that they meet the highest standards of quality and performance.

With our expertise and cutting-edge technology, we can provide you with the best CNC machining materials that will deliver exceptional results. Whether you need materials for automotive components, electronics, or consumer goods, we have you covered. Contact us today to discuss your project needs and get the right CNC machining materials for your projects.

FAQ

What are the essential questions for selecting the right CNC material?

The essential questions to consider when selecting CNC machining materials include the end-use of the part, environmental conditions, required strength and dimensional tolerance, fastening method, operating temperatures, weight and stress capacity, and overall project costs.

What are the common metal materials for CNC machining?

Common metal materials for CNC machining include aluminum, stainless steel, carbon steel, copper and its alloys, titanium, and magnesium.

What are the types of plastic materials for CNC machining?

Plastic materials commonly used in CNC machining include acrylic, polypropylene, acetal, nylon, ABS, UHMW-PE, polycarbonate, and PEEK.

What factors should I consider when selecting CNC machining materials?

Factors to consider when selecting CNC machining materials include the end-use of the part, environmental conditions, required strength and dimensional tolerance, fastening method, operating temperatures, weight and stress capacity, and overall project costs.

What are some tips for machining different materials with CNC processes?

When machining metal materials, it is important to use appropriate cutting tools and speeds to ensure precision and avoid damage to the material. For plastic materials, considerations include controlling heat buildup and using proper cutting techniques.

How do I choose the right CNC machining material for my projects?

To choose the right CNC machining material for your projects, consider the specific requirements of your part and evaluate the properties and capabilities of different materials. Consulting with a trusted CNC machining company can also provide recommendations based on your project specifications and budget.

What is Precision Machining Pro?

Precision Machining Pro is a trusted provider of high-quality CNC machining materials. With cutting-edge technology and expertise, we offer a wide range of materials that meet the highest standards of precision and durability.

How can I get the right CNC machining materials for my projects?

Contact Precision Machining Pro today to learn more about our CNC machining services and how we can help you get the right CNC machining materials for your projects.

Source Links

- https://sybridge.com/material-for-your-cnc-machining-project/

- https://www.americanmicroinc.com/resources/cnc-machining-material-guide/

- https://waykenrm.com/blogs/cnc-machining-materials/