Welcome to Precision Machining Pro, where we offer specialized CNC machined parts that provide tailored solutions for a wide range of industries. Our precision engineering expertise and advanced CNC machining capabilities enable us to deliver high-quality custom-machined parts that meet your specific requirements. Whether you need rapid prototyping or production parts, our CNC machining services are here to serve you.

At Precision Machining Pro, we pride ourselves on our state-of-the-art machine shop and dedicated team of professionals. With our extensive experience in CNC fabrication and prototyping, we can bring your ideas to reality with precision and efficiency. Our custom CNC machining services ensure that each part is meticulously crafted to the highest standards of quality.

With our CNC milling and CNC turning capabilities, we can manufacture complex components with tight tolerances. Our 3 & 5-axis milling machines allow for the production of intricate designs, while our turning centers are ideal for creating round or tubular parts. No matter the complexity or volume, we have the expertise and equipment to deliver high-quality CNC machined parts.

As a leading CNC machining company, we understand the importance of delivering products on time. Our industry-leading turnaround times ensure that you receive your specialized CNC machined parts when you need them. We also offer competitive prices without compromising on quality, making us your trusted partner for precision CNC parts.

Key Takeaways:

- Specialized CNC machined parts offer tailored solutions for various industries.

- Precision engineering and advanced CNC machining techniques ensure high-quality custom-machined parts.

- CNC milling and turning capabilities enable the production of complex components with tight tolerances.

- Precision Machining Pro offers competitive prices and industry-leading turnaround times.

- Trust us to deliver the specialized CNC machined parts you need, on time and with precision.

CNC Machining Capabilities

If you’re in need of specialized CNC machined parts, it’s crucial to have an understanding of the CNC machining capabilities offered by manufacturers. CNC machining is a highly precise and efficient manufacturing process that utilizes computer numerical control machines to produce custom components. Let’s delve into the key capabilities associated with CNC machining.

CNC Milling

CNC milling is a versatile machining process that allows for the creation of parts with complex geometries. It involves the use of CNC mills, which use rotary cutting tools to remove material from a workpiece. This process enables the production of precise and intricate components, making it suitable for various industries.

CNC Turning

CNC turning is another essential capability in CNC machining. It is used to create cylindrical parts by cutting away excess material from a rotating workpiece. CNC turning centers employ a wide range of cutting tools to produce both external and internal features, resulting in high-quality components for specialized applications.

EDM and Grinders

In addition to CNC milling and turning, manufacturers often offer options for electrical discharge machining (EDM) and grinding services. EDM utilizes electrical sparks to erode material and create intricate shapes. Grinding, on the other hand, is a process that utilizes abrasive wheels to achieve fine surface finishes. These additional capabilities further enhance the precision and versatility of CNC machining.

Tolerances and Lead Times

When it comes to specialized CNC machined parts, precision is of utmost importance. CNC machining can achieve incredibly tight tolerances, with some manufacturers capable of achieving tolerances as tight as 0.05 mm (0.0020 in). This level of precision ensures that the finished components meet the specific requirements of the project.

Lead times for production are also an essential consideration. While it may vary depending on the complexity of the parts and the manufacturer’s workload, typical lead times for specialized CNC machined parts range around 5 business days. This allows for efficient production without compromising on quality.

Overall, understanding the CNC machining capabilities available is crucial for making informed decisions when it comes to procuring specialized CNC machined parts.

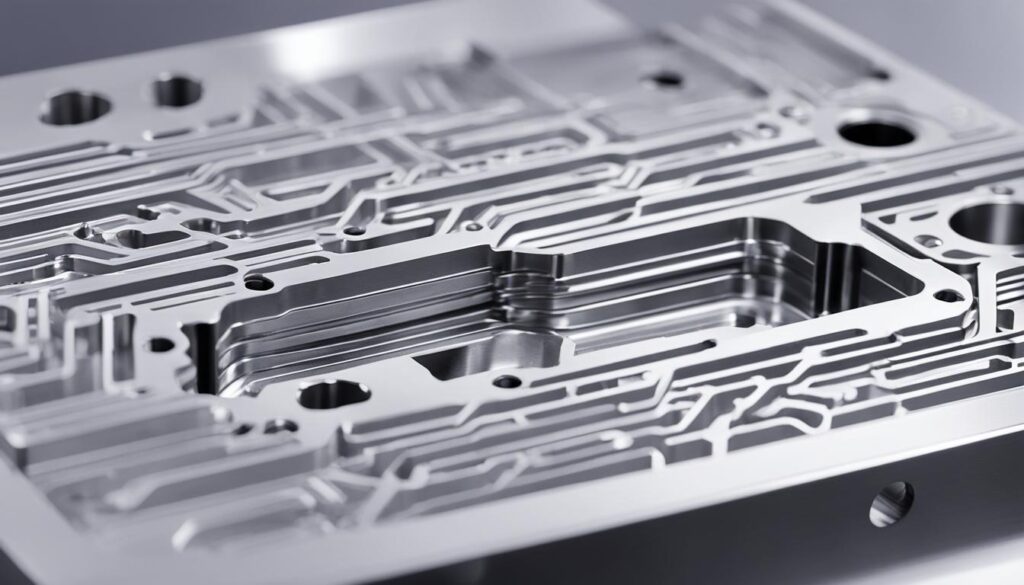

3 & 5 Axis CNC Milling

Specialized CNC machining services offer access to an extensive range of milling centers, providing the capability to produce complex and intricate designs with exceptional precision and accuracy. With over 1,000 milling centers available, including standard 3-axis mills, indexed 3+2-axis mills, and fully-continuous 5-axis mills, manufacturers can deliver high-quality specialized CNC machined parts that meet diverse client requirements.

The utilization of multiple axes in CNC milling allows for enhanced versatility and efficiency in machining processes. By enabling simultaneous movement along multiple axes, these advanced machines can achieve intricate geometries and complex contours that would be challenging to produce using traditional machining methods. This results in the creation of specialized CNC machined parts that exhibit superior accuracy, surface finish, and dimensional consistency.

Whether your project demands the precision of 3-axis mills, the added flexibility of indexed 3+2-axis mills, or the complete freedom of fully continuous 5-axis mills, specialized CNC machining services can accommodate a wide range of design complexities and geometric requirements. The state-of-the-art milling centers coupled with the expertise of experienced machinists ensure the production of customized and high-quality CNC machined parts.

Advantages of 3 & 5 Axis CNC Milling:

- Capability to produce complex and intricate designs

- Enhanced precision and dimensional accuracy

- Superior surface finishes

- Efficient machining processes

- Ability to accommodate diverse design requirements

At Precision Machining Pro, we leverage our advanced 3 & 5-axis CNC milling capabilities to deliver specialized CNC machined parts that meet the highest standards of quality and precision. Our team of skilled machinists and engineers ensures that each project is executed with meticulous attention to detail and adherence to strict manufacturing tolerances.

Image:

CNC Turning

Specialized CNC machining services offer access to over 300 turning centers, including Swiss lathes and multi-axis mill turns. CNC turning is a versatile machining process used in the production of specialized CNC machined parts for various industries. It is particularly useful for creating round or tubular components and allows for the machining of complex external geometries and internal holes.

Turning centers, also known as lathes, are equipped with a rotating workpiece and cutting tools that move in different axes to shape the material. Swiss lathes, named after their origin in the Swiss watchmaking industry, are known for their precision and ability to handle small, intricate parts. Multi-axis mill turns to combine the capabilities of both turning and milling machines, allowing for even greater complexity and efficiency in the production of specialized CNC machined parts.

With CNC turning, manufacturers can achieve high levels of accuracy and repeatability, resulting in precise components that meet the specific requirements of clients. This process is crucial in industries such as aerospace, automotive, medical, and consumer electronics, where specialized CNC machined parts play a vital role in the overall functionality and performance of products.

Next, we will explore a few examples of CNC machined parts in the gallery section, showcasing the capabilities and versatility of specialized CNC machining.

Gallery of CNC Machined Parts

Here is a small selection of CNC machined prototypes and end-use parts. These examples showcase the versatility and precision of specialized CNC machined parts.

1. Motor Vehicle: Aluminum 7075-T6 Parts

In the motor vehicle industry, aluminum 7075-T6 parts are widely used due to their high strength-to-weight ratio and excellent corrosion resistance. These CNC-machined parts are crucial for ensuring the safety and performance of vehicles components.

2. Plate Fixtures: Mild Steel 1045 Parts

Mild steel 1045 parts are commonly used as plate fixtures for various industrial applications. With their strength, durability, and machinability, these CNC-machined parts provide reliable support and stability in manufacturing processes.

3. Industrial Automation: Aluminum 6061-T6 Parts

Aluminum 6061-T6 parts are frequently utilized in industrial automation for mechanical adapters, connectors, and brackets. The lightweight nature of these CNC-machined parts allows for easy integration and efficient operation in automated systems.

4. Academic Research: Aluminum 6082 Parts

Aluminum 6082 parts play a significant role in academic research projects, particularly in engineering and materials science. The precision and consistency of these CNC-machined parts make them ideal for testing and analysis purposes.

5. Pipe Fixing: Stainless Steel 304 Parts

Stainless steel 304 parts are commonly used for optimizing pipe fixing in various industries. These CNC-machined parts offer exceptional corrosion resistance and mechanical strength, ensuring long-lasting and reliable pipe systems.

6. Electronics Enclosures: Aluminum 6063 Parts

Aluminum 6063 parts are extensively used in the electronics industry for enclosures and housing components. The excellent thermal conductivity and electrical conductivity of these CNC machined parts help dissipate heat and protect sensitive electronic devices.

7. Academic Research: PEEK Parts

PEEK (Polyether Ether Ketone) parts find applications in academia, particularly in research projects involving biomaterials and biomedical engineering. These CNC-machined parts possess exceptional chemical resistance and stiffness, making them suitable for specialized research and testing purposes.

On-demand CNC Machining Services

When it comes to specialized CNC machined parts, on-demand CNC machining services are a game-changer. These services provide rapid prototyping and production of parts through a network of specialized and experienced local and global CNC machine shops.

With on-demand CNC machining, you can quickly turn your design ideas into reality. Whether you need a prototype to test and validate your concept or production parts for your final product, these services have you covered. The process is simple: you upload your designs securely, and the CNC machine shops will provide instant quotes for your projects.

Rapid prototyping is a key benefit of on-demand CNC machining. It allows you to iterate and refine your design before committing to mass production. This saves both time and money by identifying and addressing any design flaws or improvements early on. By leveraging the expertise of specialized CNC machine shops, you can ensure that your prototypes are machined with the highest level of precision and quality.

Additionally, on-demand CNC machining services provide production parts for various industries. Whether it’s a small batch run or a larger production order, these services can meet your volume needs. By tapping into a network of local and global CNC machine shops, you can take advantage of their expertise and capacity to deliver high-quality specialized CNC machined parts.

One of the key advantages of on-demand CNC machining services is the quick turnaround times they offer. Gone are the days of long lead times and delays in the manufacturing process. With the accessibility to a vast network of CNC machine shops, your parts can be machined and delivered efficiently, saving you valuable time and ensuring your project stays on schedule.

So, whether you need rapid prototyping or production parts, on-demand CNC machining services provide a cost-effective and efficient solution. By leveraging the expertise of specialized CNC machine shops, you can bring your design ideas to life, confident in the quality and precision of your specialized CNC machined parts.

From CNC Prototyping to Low-volume Production

At Precision Machining Pro, we offer a comprehensive range of services, catering to all your CNC machining needs. Whether you require CNC prototyping or low-volume production of specialized CNC machined parts, our team of experts is here to assist you.

CNC Prototyping:

Our CNC prototyping services allow you to verify your designs and conduct extensive engineering testing before committing to full-scale production. By creating prototypes using our state-of-the-art CNC machines, you can ensure that your parts meet all desired specifications and functionality requirements. This not only saves time and resources but also improves the overall efficiency and effectiveness of your manufacturing process.

Low-Volume Production:

In addition to CNC prototyping, we specialize in low-volume production of specialized CNC machined parts. Our rapid manufacturing capabilities ensure quick turnaround times, without compromising on quality. Whether you need a few pieces or a limited production run, our experienced team is equipped to meet your low-volume production needs.

Our expertise in CNC machining, combined with our attention to detail, allows us to produce low-volume specialized CNC machined parts with utmost precision and accuracy. We understand the importance of quality in low-volume production, and we strive to deliver parts that consistently meet and exceed your expectations.

Partnering with Precision Machining Pro for your CNC prototyping and low-volume production needs ensures that you receive top-notch service and outstanding results. Contact us today to discuss your project requirements and benefit from our industry-leading expertise.

Case Applications of CNC Machined Parts

Specialized CNC machined parts find diverse applications across various industries. Their precision and quality make them essential components in the marine, automotive, robotics, consumer electronics, and industrial automation sectors.

In marine, CNC machined parts play a critical role in the production of complex components, such as bollards, structural elements, and critical deck hardware. The high precision and reliability of CNC machining ensure strict adherence to industry standards and regulations.

The automotive industry relies on CNC-machined parts for various applications, including engine components, transmission systems, suspension parts, and interior trim. CNC machining allows for the production of high-performance, durable, and precise parts that meet the demanding requirements of the automotive sector.

In the Robotics field, specialized CNC machined parts are used in the manufacturing of parts for robotics in equipment devices for both production line and shipping robots. Due to the critical nature of medical applications, CNC machining ensures the production of accurate, and compatible parts that meet the stringent standards of the robotics industry.

Consumer electronics heavily rely on CNC machined parts for the production of intricate enclosures, connectors, heat sinks, and other precision components. The accurate and efficient manufacturing process of CNC machining enables the production of small, complex, and aesthetically appealing parts for electronic devices.

Industrial automation utilizes CNC machined parts for the fabrication of robotic systems, production line components, sensors, and control panels. CNC machining enables the production of intricate and reliable parts that optimize the efficiency and performance of automated systems.

“From complex aerospace parts to intricate medical components, specialized CNC machined parts play a crucial role in various industries.”

With the increasing demand for specialized CNC machined parts in various sectors, precision machining companies like Precision Machining Pro offer customized solutions to meet the unique needs of different industries. By leveraging advanced CNC machining capabilities, these companies provide reliable, high-quality parts that drive innovation and efficiency across diverse applications.

CNC Machining Materials & Finishes

Specialized CNC machining can be performed on various materials, including plastics and metals. Precision Machining Pro offers over 30 engineering-grade plastic and metal materials for CNC machining. These materials are carefully selected to ensure optimal performance and durability for specialized CNC machined parts.

When it comes to plastics, Precision Machining Pro provides options such as ABS, PMMA (acrylic), PC (polycarbonate), POM (acetal), PA (nylon), and PEEK. These materials offer a range of mechanical properties, chemical resistance, and thermal stability, making them suitable for different applications.

For metal CNC machining, Precision Machining Pro offers materials like aluminum alloys (e.g., 6061-T6, 7075-T6), stainless steel (e.g., 304, 316), titanium, brass, and copper. These metals provide excellent strength, corrosion resistance, and conductivity, allowing for the production of high-quality precision parts.

To enhance the aesthetics and functionality of specialized CNC machined parts, Precision Machining Pro offers a wide selection of surface finishes. These finishes include:

- Sanding: Provides a smooth and uniform surface finish.

- Sandblasting: This creates a matte or textured finish.

- Mirror polishing: Achieves a highly reflective and smooth surface.

- Painting: Adds color and protection to the parts.

- Printing: Allows for branding and labeling.

- Anodizing: Offers corrosion resistance and color options for aluminum parts.

- Electroplating: Provides a protective metal coating and enhances appearance.

- Powder coating: This creates a durable and decorative finish.

These surface finishes can be combined to achieve the desired appearance and functionality of specialized CNC machined parts, whether they are for functional prototypes or end-use products.

To see examples of our CNC machined parts and the range of material options and surface finishes available, check out our gallery here.

| Material | Properties | Applications |

|---|---|---|

| ABS | Durable, impact-resistant, good chemical resistance | Prototypes, casings, consumer products |

| PMMA | Transparent, good optical properties, weather-resistant | Lighting fixtures, displays, optical components |

| PC | High impact strength, good dimensional stability | Automotive parts, electrical housings, medical equipment |

| POM | Low friction, excellent dimensional stability | Gears, bearings, precision engineering components |

| PA | High strength, good wear resistance, moisture resistant | Gears, bushings, structural components |

| PEEK | High-temperature resistance, excellent mechanical properties | Aerospace components, medical implants, oil & gas applications |

| Aluminum alloys | Lightweight, good strength-to-weight ratio, corrosion-resistant | Aerospace parts, automotive components, electronic enclosures |

| Stainless steel | High strength, corrosion-resistant, hygienic | Medical instruments, food processing equipment, marine parts |

| Titanium | Lightweight, high strength-to-weight ratio, excellent corrosion resistance | Aerospace components, medical implants, sports equipment |

| Brass | Good electrical conductivity, corrosion-resistant | Electrical connectors, plumbing fittings, musical instruments |

| Copper | Excellent electrical conductivity, thermal conductivity | Electrical components, heat exchangers, electronic devices |

By using the right materials and finishes, specialized CNC machined parts can meet specific requirements for functionality, durability, and appearance.

Conclusion

In conclusion, specialized CNC machined parts provide tailored solutions for a wide range of industries. Whether you need complex and precise components or rapid prototyping for design verification, CNC machining capabilities, such as 3 & 5-axis milling and CNC turning, offer the precision and efficiency required for your projects.

When it comes to specialized CNC machining, Precision Machining Pro CNC machining services are a reliable choice. With their expert guidance, competitive prices, and industry-leading turnaround times, they ensure that your projects are completed on time and within budget. Additionally, Precision Machining Pro offers a wide range of materials and finishes, allowing you to customize your specialized CNC machined parts according to your specific needs.

From robotics to automotive, marine to consumer electronics, specialized CNC machined parts play a crucial role in the manufacturing and fabrication processes of various industries. They provide the necessary precision, quality, and reliability required for these applications. Whether you are in the prototyping phase or low-volume production, specialized CNC machined parts are essential components that contribute to the success of your projects.

So, if you are looking for high-quality specialized CNC machined parts, look no further than WayKen’s CNC machining services. With their expertise, state-of-the-art facilities, and commitment to customer satisfaction, they are the go-to choice for all your CNC machining needs.

FAQ

What are specialized CNC machined parts?

Specialized CNC machined parts are precision-engineered components that are manufactured using advanced CNC machining techniques. They are tailor-made to meet the specific requirements of clients in various industries.

How are specialized CNC machined parts manufactured?

Specialized CNC machined parts are manufactured using computer numerical control machines to cut, drill, mill, and grind metal or plastic materials. These advanced machining techniques result in high-quality, customized components.

What are the capabilities of CNC machining?

CNC machining can produce a wide range of parts, from simple workholdings to complex geometries. With a variety of CNC mills and turning centers available, tolerances as tight as 0.05 mm can be achieved in a typical lead time of 5 business days.

What is 3 & 5-axis CNC milling?

3 & 5-axis CNC milling refers to the capability of CNC machines to operate on multiple axes, allowing for the production of complex and intricate designs with high precision and accuracy.

What is CNC turning?

CNC turning is a machining process that is ideal for creating round or tubular parts. It allows for the machining of complex external geometries and internal holes, making it widely used in the production of specialized CNC machined parts.

Can you provide examples of specialized CNC machined parts?

Yes, examples of specialized CNC machined parts include aluminum 7075-T6 parts used in the aerospace industry, mild steel 1045 parts used as plate fixtures, aluminum 6061-T6 parts for mechanical adapters in industrial automation, and stainless steel 304 parts optimized for pipe fixing, among others.

What are on-demand CNC machining services?

On-demand CNC machining services provide rapid prototyping and production of parts through a network of specialized and experienced local and global CNC machine shops. Customers can upload their designs securely and receive instant quotes for their projects.

What industries use specialized CNC machined parts?

Specialized CNC machined parts are used in industries such as aerospace, automotive, medical, consumer electronics, and industrial automation. CNC machining provides the precision and quality required for these applications.

What materials and finishes are available for CNC machining?

Precision Machining Pro offers over 30 engineering-grade plastic and metal materials for CNC machining. These materials can be finished with a wide range of surface finishes, including sanding, sandblasting, mirror polishing, painting, anodizing, electroplating, and powder coating.