Welcome to Precision Machining Pro, your go-to source for high-quality custom parts produced through precision CNC milling services. With our state-of-the-art technology and expert team, we offer unparalleled precision and accuracy in the manufacturing process. Whether you need complex geometries, tight tolerances, or versatility in material options, we have the capabilities to meet your exact specifications.

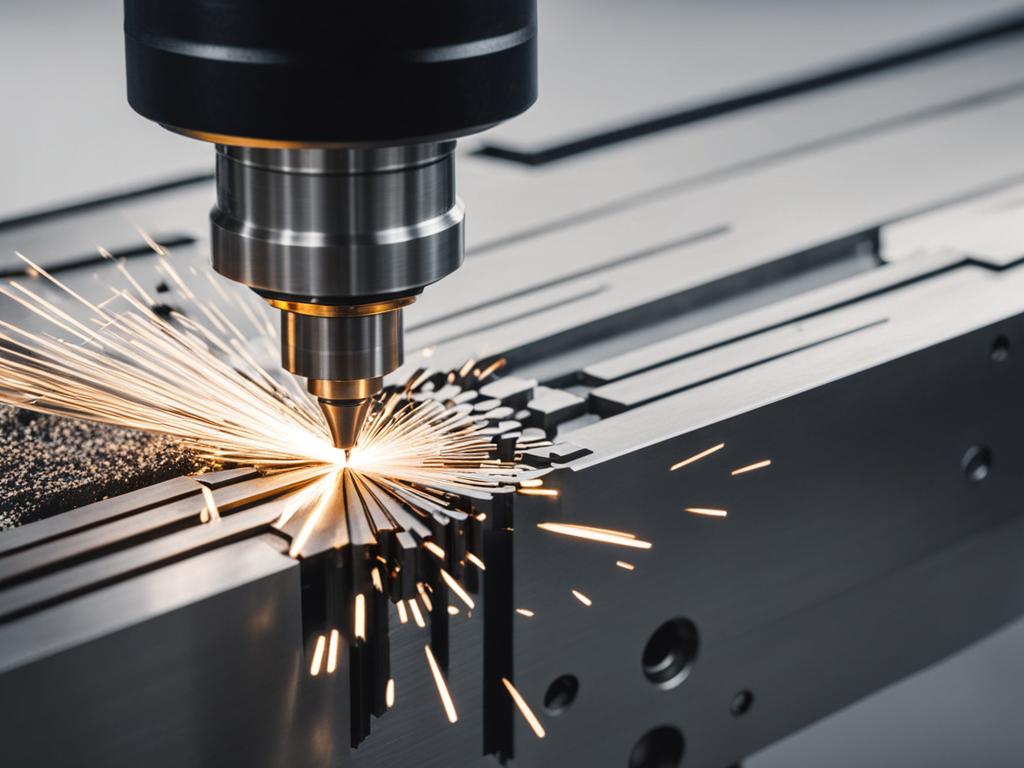

CNC machining is revolutionizing the manufacturing industry with its computer-controlled precision and repeatability. Among the various CNC techniques, CNC milling stands out as a widely used method for creating custom parts with tight tolerances. Our skilled technicians utilize advanced milling machines to remove material from the workpiece, resulting in parts that meet the highest standards of quality and precision.

By partnering with Precision Machining Pro, you can take advantage of our expertise in CNC milling services to achieve your desired custom parts. We understand the importance of precision and accuracy in industries such as aerospace, automotive, and medical. Our commitment to excellence ensures that each part we produce meets the required specifications, allowing you to enhance the performance and quality of your products.

Key Takeaways:

- CNC milling is a highly precise manufacturing process that utilizes computer numerical control to create custom parts.

- The milling machines used in CNC milling are programmed with instructions to ensure precise and repeatable production.

- CNC milling offers advantages such as greater precision, the ability to produce complex geometries, and versatility in material options.

- The CNC milling process involves securing the workpiece, selecting appropriate cutting tools, and programming the machine.

- Precision CNC milling services cater to various industries and require the expertise of reputable service providers.

What is CNC Milling?

CNC milling is a machining process that utilizes computer numerical control to automate the operation of milling machines. It involves the use of cutting tools to remove material from a workpiece, creating the desired shape and dimensions. The technology behind CNC milling has revolutionized the manufacturing industry, allowing for precise and repeatable production of custom parts.

Using advanced milling machines and tools, CNC milling offers unparalleled precision and accuracy. The process begins with the programming of precise instructions that dictate the movements of the cutting tools. This ensures consistent and reliable results, making CNC milling an ideal choice for precision machining.

One of the key benefits of CNC milling is the variety of tools and techniques it employs. Carbide and diamond cutting tools, for example, are used to achieve high levels of precision and surface quality. These cutting tools are designed to withstand the demands of the milling process and deliver superior performance.

“CNC milling combines computer control with milling technology, enabling manufacturers to produce intricate parts with utmost precision.”

CNC milling also allows for the production of complex geometries that would be challenging to achieve with manual machining. The use of computer control enables the milling machine to execute intricate movements and create intricate shapes with ease.

Furthermore, CNC milling technology offers versatility in terms of materials. It can work with a wide range of materials, including metals like aluminum, steel, and brass, as well as various engineering plastics. This flexibility enables the production of custom parts for diverse applications and industries.

Benefits of CNC Milling:

- Precise and repeatable production of custom parts

- Advanced machining techniques and tools

- Ability to create complex geometries

- Wide range of compatible materials

In summary, CNC milling is a sophisticated machining process that combines computer numerical control and milling technology to produce high-precision custom parts. The technology, tools, and techniques employed in CNC milling offer exceptional accuracy and versatility, making it an indispensable choice for precision machining applications.

Advantages of CNC Milling

CNC milling offers several advantages over traditional machining methods. First, it provides greater precision and accuracy, ensuring that each part produced meets the required specifications. This is especially important in industries that require tight tolerances, such as aerospace and medical.

Second, CNC milling allows for the production of complex geometries that would be difficult or impossible to achieve with manual machining. The use of computer control enables the milling machine to execute intricate movements and create intricate shapes with ease.

Lastly, CNC milling offers versatility in terms of materials. It can work with a wide range of materials, including plastics and metals, providing flexibility in the production of custom parts.

| Advantages of CNC Milling | |

|---|---|

| Precision and accuracy | Allows for tight tolerances in industries such as aerospace and medical |

| Complex geometries | Enables the creation of intricate shapes with ease |

| Versatility in materials | Works with a wide range of materials, providing flexibility |

CNC Milling Process

The CNC milling process involves a series of operations and techniques that are crucial for achieving the desired results. To begin, the workpiece is securely mounted on the milling machine’s bed or table to ensure stability during the milling process.

Next, specific cutting tools, such as end mills and drills, are carefully selected based on the unique requirements of the part being produced. These cutting tools are loaded into the machine’s tool holder and positioned accurately to make precise cuts and remove material from the workpiece.

Once the cutting tools are in place, the milling machine is programmed with detailed instructions that control the movements of the cutting tools. These instructions encompass critical parameters such as feed rate, spindle speed, and tool path, which dictate the speed and direction of the cutting tools.

With the programmed commands in place, the milling machine executes the instructions, accurately cutting and shaping the workpiece to create the desired part. This precise control over the cutting tools and the workpiece allows for the production of highly accurate and intricately designed custom parts.

CNC Milling Services

When it comes to precision machining solutions, CNC milling services provided by specialized companies are the go-to choice for industries such as automotive, aerospace, and electronics. These services offer expertise, advanced milling techniques, and cutting-edge tools to produce custom parts that meet the exact specifications and tolerances required by clients.

CNC milling service providers leverage their experience and knowledge to deliver high levels of accuracy and quality. By utilizing a variety of milling techniques and state-of-the-art tools, they ensure that the custom parts are manufactured to the highest standards.

In addition to their expertise, CNC machining centers often have multiple machines. This allows them to handle projects with increased production capacity, ensuring efficient turnaround times and meeting even the most demanding production schedules.

As CNC milling involves the precise removal of material from the workpiece, it requires expertise, attention to detail, and the right tools. CNC milling service providers excel in these areas, providing a comprehensive solution for businesses in need of custom parts with unparalleled precision and quality.

CNC Milling Materials

In precision machining, CNC milling offers the flexibility to work with a wide range of materials, allowing for the production of custom parts with exceptional precision and quality. Whether it’s metals or plastics, CNC milling service providers have the expertise and resources to cater to various applications and industries.

Common materials used in CNC milling include:

- Aluminum: Lightweight and corrosion-resistant, aluminum is often preferred for its excellent strength-to-weight ratio. It is commonly used in aerospace, automotive, and electronics industries.

- Steel: Known for its strength and durability, steel is a versatile material suitable for a wide range of applications. It is commonly used in manufacturing heavy machinery, automotive components, and structural parts.

- Brass: With its excellent machinability and aesthetic appeal, brass is often used in applications where corrosion resistance and a decorative finish are required. It finds applications in plumbing fixtures, musical instruments, and electrical connectors.

- Various Engineering Plastics: From nylon to polycarbonate, engineering plastics offer a range of beneficial properties such as high strength, chemical resistance, and low friction. These materials are widely used in industries such as automotive, electronics, and consumer goods.

When selecting the appropriate material for CNC milling, it’s essential to consider the specific requirements of the part. Factors such as strength, durability, heat resistance, and aesthetic appeal play a crucial role in material selection.

Table: Comparison of CNC Milling Materials

| Material | Advantages | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good strength-to-weight ratio | Aerospace components, automotive parts, electronics enclosures |

| Steel | High strength, durability, excellent machinability | Heavy machinery, automotive components, structural parts |

| Brass | Good machinability, corrosion resistance, decorative finish | Plumbing fixtures, musical instruments, electrical connectors |

| Engineering Plastics | Various beneficial properties (e.g., strength, chemical resistance) | Automotive parts, electronics components, consumer goods |

CNC Milling Applications

CNC milling is a widely utilized technique in various industries for the production of custom parts. The exceptional precision offered by CNC milling makes it particularly suitable for applications that require tight tolerances, such as aerospace components and medical devices. The ability to achieve high levels of accuracy ensures that each part meets the required specifications, contributing to overall product quality and performance.

In the automotive industry, CNC milling plays a crucial role in the manufacturing of engine components and chassis parts. The precision milling techniques employed enable the creation of complex geometries and ensure the seamless integration of these parts into the overall vehicle design. CNC milling also facilitates the production of molds and prototypes, providing an efficient and cost-effective solution for testing and refining designs before mass production.

CNC milling excels in the creation of intricate details and precise dimensions, making it invaluable in architectural and industrial designs. The versatility of this technique allows for the realization of complex shapes and forms, enabling designers to bring their visions to life with utmost accuracy. Whether it’s crafting delicate patterns or creating structural elements with intricate geometries, CNC milling offers the precision and flexibility required to achieve exceptional results.

With CNC milling, the possibilities are virtually limitless. From aerospace to automotive, from healthcare to architecture, this technique empowers industries to produce custom parts with unrivaled precision and consistency.

| Industry | Applications |

|---|---|

| Aerospace | Component manufacturing, aircraft interiors |

| Medical | Prosthetics, surgical instruments, medical device components |

| Automotive | Engine components, chassis parts |

| Prototyping | Molds, models, functional prototypes |

| Architectural | Complex facades, decorative elements |

| Industrial Design | Intricate patterns, structural elements |

CNC Milling Service Providers

When it comes to obtaining precision custom parts through CNC milling, choosing the right service provider is crucial. As a Precision Machining Pro, I understand the importance of partnering with a reputable and reliable company that can meet your specific requirements and deliver high-quality results.

When selecting a CNC milling service provider, consider their track record in delivering precision machining services. Look for a provider with a proven history of producing parts with exceptional accuracy and precision. This expertise ensures that your custom parts are manufactured to the highest standards, meeting your specifications every time.

Experience is also essential when choosing a CNC milling service provider. Opt for a company that has extensive knowledge and expertise in the field of precision machining. Their experience will enable them to understand the unique challenges and requirements of your project, ensuring that they can deliver the best results.

It’s also important to consider the types of milling machines and technologies the service provider utilizes. Advanced CNC milling machines equipped with the latest technologies can enhance the precision and accuracy of the milling process. They offer greater control and flexibility, enabling the production of even the most intricate and complex parts.

In addition, assess the service provider’s capabilities in terms of production capacity, turnaround times, and additional services. A well-equipped CNC milling service provider should have the capacity to handle your project efficiently, ensuring timely delivery of your custom parts. They should also offer additional services such as finishing and assembly, providing a comprehensive solution for all your precision machining needs.

Benefits of partnering with a reliable CNC milling service provider:

- Assurance of high-quality precision parts

- Expertise and experience in precision machining

- Utilization of advanced milling machines and technologies

- Efficient production capacity and fast turnaround times

- Additional services such as finishing and assembly

| Benefits of partnering with a reliable CNC milling service provider: |

|---|

| Assurance of high-quality precision parts |

| Expertise and experience in precision machining |

| Utilization of advanced milling machines and technologies |

| Efficient production capacity and fast turnaround times |

| Additional services such as finishing and assembly |

By selecting a reliable CNC milling service provider, you can be confident that your custom parts will be manufactured to the highest standards, meeting your precise requirements. Their expertise, advanced technologies, and efficient production processes ensure the delivery of top-quality precision machining services.

When it comes to precision CNC milling services, trust the experts who can provide exceptional results. Partner with a reputable CNC milling service provider and experience the difference in quality, accuracy, and efficiency.

Conclusion

In conclusion, CNC milling plays a pivotal role in precision machining, offering a multitude of advantages for the production of custom parts. Its exceptional precision and accuracy make it an indispensable manufacturing process, capable of creating intricate geometries with ease. Additionally, CNC milling’s versatility extends to a wide range of materials, enabling the production of custom parts in various industries.

By collaborating with a renowned CNC milling service provider like Precision Machining Pro, businesses can ensure the creation of high-quality parts that meet their exact specifications. Whether it’s for prototyping, low-volume production, or large-scale manufacturing, CNC milling services provide an efficient and reliable solution for achieving unparalleled precision.

With CNC milling’s ability to deliver tight tolerances, accommodate complex designs, and work with different materials, it has become a go-to method for producing custom parts. By harnessing the expertise of a trusted CNC milling service provider, companies can confidently navigate the challenges of precision machining and deliver exceptional results to their customers.

FAQ

What is CNC milling?

CNC milling is a machining process that uses computer numerical control to automate the operation of milling machines. It involves the use of cutting tools to remove material from a workpiece, creating the desired shape and dimensions.

What are the advantages of CNC milling?

CNC milling offers several advantages over traditional machining methods. It provides greater precision and accuracy, allows for the production of complex geometries, and offers versatility in terms of materials.

How does the CNC milling process work?

The CNC milling process involves mounting the workpiece on the milling machine, selecting the appropriate cutting tools, and programming the machine with precise instructions to control the movements of the cutting tools.

What are CNC milling services?

CNC milling services are offered by specialized companies that have the expertise and equipment to provide precision machining solutions. They produce custom parts based on client specifications using advanced milling techniques and tools.

What materials can be used in CNC milling?

CNC milling can work with a wide range of materials, including plastics and metals. Common materials used include aluminum, steel, brass, and various engineering plastics.

What are the applications of CNC milling?

CNC milling is widely used in industries such as aerospace, automotive, and electronics for the production of custom parts. It is also used for manufacturing molds, prototypes, and creating complex geometries in architectural and industrial designs.

How do I choose a CNC milling service provider?

When seeking CNC milling services, it is important to choose a reputable service provider that has experience, expertise, and utilizes the right milling machines and technologies. Consider factors such as production capacity, turnaround times, and additional services offered.

Source Links

- https://www.xometry.com/capabilities/cnc-machining-service/

- https://www.protolabs.com/services/cnc-machining/

- https://www.3erp.com/services/cnc-machining/