When it comes to precision CNC-turning, selecting the right machining supplier is paramount for achieving exceptional results. Whether you require CNC machining services, CNC turning services, or custom CNC parts, there are several essential factors to consider when choosing a reliable CNC machining company that meets your specific needs.

As a Precision Machining Pro, I have compiled a list of 10 expert tips to help you make an informed decision and find the perfect CNC machining partner for your next project.

Key Takeaways:

- Reliability is crucial when selecting a CNC machining supplier.

- Consider the production capacity of the CNC machining company.

- Technological equipment plays a significant role in the precision of CNC machining.

- Quality control ensures the delivery of accurate and high-quality machined parts.

- Customer feedback is a valuable indicator of a machining shop’s reputation.

Reliability

When it comes to choosing a CNC machining supplier, reliability is a crucial factor that should not be overlooked. A reliable manufacturer is essential for ensuring smooth operations and minimizing downtime. It’s important to select a CNC machining supplier that provides durable and reliable CNC machines, as this can significantly impact the quality and efficiency of your machining projects.

Investing in CNC machines from renowned suppliers like Worthy Hardware ensures that you receive fine-quality equipment with high reliability and value. These trusted manufacturers prioritize durability, offering CNC machines that are built to last. By choosing reliable CNC machines, you can avoid frequent repairs, reduce production delays, and establish a long-term partnership with a reputable supplier.

Reliable CNC machines are designed to withstand the demands of precision machining, delivering consistent, accurate results with minimal disruptions. Whether you require CNC machining or CNC turning services, choosing reliable equipment is vital for achieving optimal performance and maximizing productivity.

Additionally, reliable CNC machines offer long-term cost savings. While cheaper options may seem tempting, they often come with hidden costs such as frequent breakdowns, subpar results, and compromised reliability. Investing in durable CNC machines from a trusted manufacturer ensures that you receive high-quality equipment that will serve you well in the long run.

Overall, when selecting a CNC machining supplier, prioritize reliability to ensure consistent performance, minimal downtime, and long-term success. By choosing a manufacturer like Worthy Hardware that provides reliable CNC machines, you can enhance the reliability and efficiency of your precision machining projects.

Production Capacity

Understanding the production capacity of a CNC machining supplier is essential. When choosing a company to handle your precision CNC machining projects, it’s important to find one that can match your specific production needs. Some machining shops specialize in prototype production and small-batch machining, while others can handle mass-volume production. Working with a company like Worthy Hardware, you can be confident that your orders will be handled efficiently and delivered on time, regardless of whether you require low-volume, prototype, or mass-volume production.

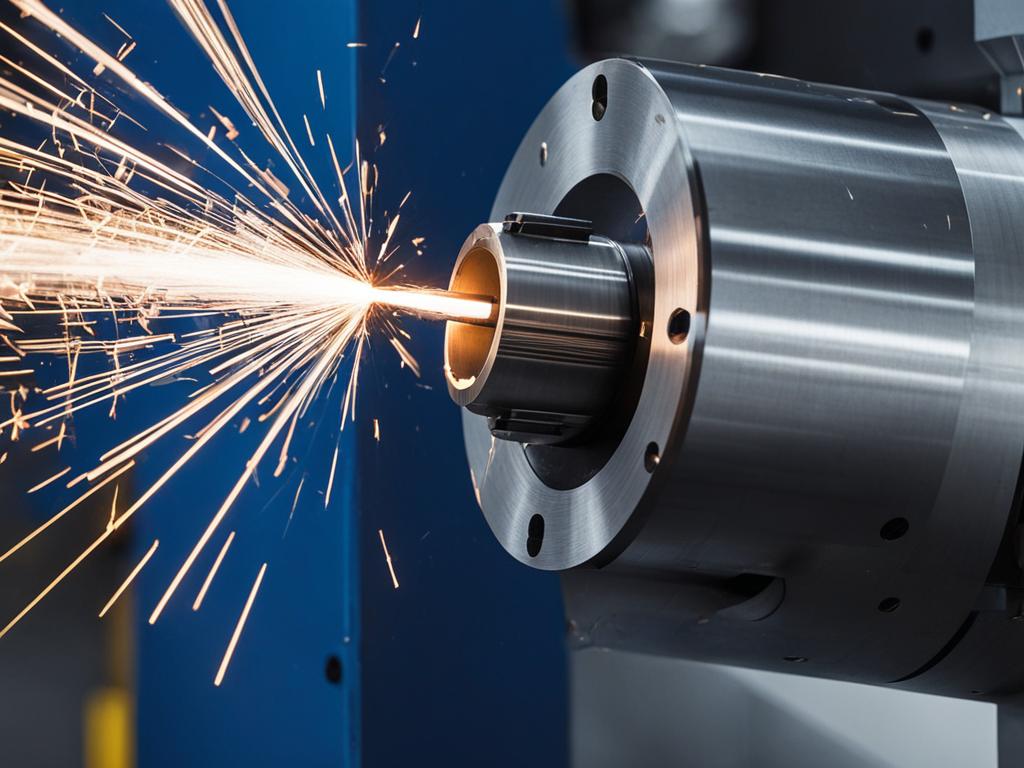

Technological Equipment for CNC turning

When it comes to precision CNC machining, the quality of the technological equipment used by a manufacturer plays a vital role in achieving outstanding results. Choosing a CNC machining shop that utilizes high-quality, up-to-date equipment and machinery is crucial for ensuring precision and efficiency in the manufacturing process.

At Precision Machining Pro, we understand the importance of technological equipment in delivering top-notch CNC machining services. That’s why we rely on industry-leading brands such as Mori Seiki, Toyoda, Fadal, and Okuma to provide cutting-edge solutions to our customers.

These renowned brands are known for their expertise in producing reliable CNC equipment that offers exceptional performance and accuracy. By utilizing the latest technological advancements, we can guarantee superior quality in every machined part we deliver.

Our state-of-the-art CNC machines are equipped with advanced features and capabilities, enabling us to handle complex machining projects with precision and efficiency. With our commitment to staying at the forefront of technological advancements, we continuously invest in upgrading our equipment to meet the evolving demands of our customers.

By choosing Precision Machining Pro as your CNC machining partner, you can be confident in our ability to leverage advanced technological equipment to deliver high-quality, precise, and reliable machined parts that meet your exact specifications.

The Advantages of Our Technological Equipment

Investing in technologically advanced CNC machining equipment offers numerous advantages that translate into superior quality and efficiency in the machining process. Here are some key benefits:

- Enhanced Precision: Our advanced machines offer higher precision levels, resulting in machined parts with accurate dimensions and tight tolerances.

- Increased Efficiency: With faster cutting speeds and improved automation features, our equipment ensures faster turnaround times, optimizing production efficiency.

- Expanded Capabilities: Our technologically advanced equipment enables us to handle a wide range of materials and complex machining operations, providing versatility in manufacturing solutions.

- Better Surface Finish: The advanced control systems of our machines allow for optimized toolpath generation, resulting in superior surface finishes of the machined parts.

- Reliability and Consistency: Our high-quality CNC equipment guarantees reliable and consistent performance, minimizing variations and deviations in the manufacturing process.

Comparison of Technological Equipment

| Brand | Key Features | Applications |

|---|---|---|

| Mori Seiki | High-speed spindles, advanced control systems | Complex aerospace components, automotive parts |

| Toyoda | Thermal stability, precision ball screws | Medical devices, precision instruments |

| Fadal | Robust construction, fast tool change | Industrial machinery, electronics |

| Okuma | Intelligent machining technologies, multi-axis capabilities | Oil and gas equipment, heavy machinery |

Investing in the right technological equipment allows us to deliver exceptional CNC machining services that meet the highest industry standards. With Precision Machining Pro, you can count on our commitment to utilizing the latest advancements in CNC machining technology to bring your precision machining projects to life.

Quality Control

Quality control plays a vital role in the CNC machining process. As a Precision Machining Pro, I understand the importance of choosing a CNC machining company that prioritizes quality control throughout the production process. By adhering to strict quality standards, manufacturers can ensure that each machined part meets the required specifications and exceeds customer expectations.

Ensuring Accuracy and Precision

At Worthy Hardware, our commitment to quality control begins with the thorough inspection of raw materials. We carefully select materials that meet the highest quality standards to ensure optimal performance and durability of the final product.

Throughout the CNC machining process, we implement comprehensive inspection procedures to monitor the accuracy and precision of each machined part. Our team of skilled technicians utilizes advanced metrology equipment and techniques to verify dimensional accuracy, surface finish, and overall quality.

“Quality is never an accident; it is always the result of intelligent effort.”

– John Ruskin

Testing Documents and Inspection Certificates

As part of our commitment to transparency and accountability, we provide our clients with comprehensive testing documents and inspection certificates. These documents serve as proof of the rigorous quality control measures we follow and offer peace of mind that each machined part meets the required specifications.

By providing detailed documentation, we aim to build trust and confidence with our clients, allowing them to make informed decisions based on the quality and reliability of our CNC machining services.

Continuous Improvement

At Worthy Hardware, we believe in continuous improvement and strive to enhance our quality control processes continually. We closely monitor customer feedback and industry trends to identify areas for improvement and implement corrective actions when necessary.

Our dedicated quality control team is committed to maintaining the highest standards of excellence and ensures that our machining processes consistently deliver superior results.

As a Precision Machining Pro, I understand the importance of quality control in CNC machining. Choosing a CNC machining company like Worthy Hardware which prioritizes quality control means you can confidently rely on the accuracy, precision, and performance of the machined parts we deliver.

Customer’s Feedback

When it comes to selecting a CNC machining supplier, customer feedback plays a vital role in evaluating the trustworthiness and reputation of a machining shop. It provides valuable insights into the experiences and satisfaction levels of previous and current clients. Considering the feedback and testimonials from satisfied customers can help you make an informed decision.

“The CNC machining services provided by Worthy Hardware exceeded our expectations. The precision and quality of their work are exceptional. Their attention to detail and prompt communication throughout the process were impressive.”

– John Smith, CEO at Precision Machining Pro

You can find customer feedback on the company’s website or their social media pages, where clients often share their experiences. Take the time to read through the testimonials and reviews to gain a better understanding of the capabilities and reliability of the CNC machining supplier.

Companies like Worthy Hardware have a strong reputation in the industry, backed by positive customer feedback. With a global clientele, they have successfully delivered high-precision CNC machining services to various industries and satisfied customers worldwide.

By considering customer feedback, you can gain insights into the quality, reliability, and customer satisfaction provided by a CNC machining supplier. Make an informed decision by taking into account the experiences of others and choosing a company with a strong track record of delivering exceptional CNC machining services.

On-time Delivery

Timely delivery is crucial for any CNC machining business. Delays in the machining process can have a negative impact on supply and demand. That’s why it’s essential to choose a CNC machining company that values on-time delivery.

At Worthy Hardware, we understand the importance of meeting deadlines and ensuring that your machining needs are met promptly. We guarantee fast 3-day delivery of machined parts, allowing you to stay on schedule and maintain efficient production processes.

When you partner with us for your precision CNC machining projects, you can trust that we prioritize time management and provide regular updates on project schedules. Our commitment to on-time delivery sets us apart from other CNC machining suppliers, ensuring that you receive your parts exactly when you need them.

Our On-time Delivery Assurance

At Worthy Hardware, we have implemented a streamlined production process and efficient logistics system to ensure on-time delivery of your CNC machined parts. Here’s how we achieve this:

- Advanced Planning: We carefully analyze your project requirements and create a detailed production plan. By taking into account factors such as machining complexity, material availability, and workload, we optimize our production schedules to minimize lead times.

- Capacity Management: Our large production capacity allows us to handle both small-batch and high-volume orders without compromising on quality or delivery. We have a dedicated team of skilled professionals and a wide range of CNC machines, ensuring that we can meet your production demands efficiently.

- Supply Chain Optimization: We have established strong partnerships with trusted suppliers to ensure a steady supply of materials. By maintaining a well-managed inventory system, we can promptly source the required materials for your projects, reducing the risk of delays.

- Real-time Communication: We understand the importance of clear and open communication throughout the production process. Our team provides regular updates on project progress and is readily available to address any questions or concerns you may have.

- Quality Assurance: While we strive for fast delivery, we never compromise on quality. Our rigorous quality control processes ensure that every machined part meets the required specifications and passes our strict quality standards before it is shipped to you.

With our commitment to on-time delivery and attention to detail, Worthy Hardware is the reliable partner you can trust for your precision CNC machining needs. Contact us today to discuss your project requirements and experience our exceptional service firsthand.

| Benefits of On-time Delivery | Consequences of Delayed Delivery |

|---|---|

| 1. Minimal disruption to your production schedule | 1. Increased production downtime |

| 2. Satisfied customers and improved customer loyalty | 2. Negative impact on customer satisfaction and loyalty |

| 3. Increased efficiency in your supply chain | 3. Disrupted supply chain and increased costs |

| 4. Ability to meet market demands and stay competitive | 4. Loss of market share to competitors with faster delivery |

| 5. Enhanced overall productivity and profitability | 5. Decreased productivity and potential revenue loss |

Material Selection and Availability

When it comes to CNC machining, the selection and availability of materials play a crucial role in achieving the desired results. A wide range of materials, such as stainless steel, aluminum, titanium, and copper, offer different mechanical and aesthetic properties for various applications.

Having access to diverse materials is essential for flexibility in CNC machining services. That’s why it’s important to choose a CNC machining shop that offers a variety of material options.

At Precision Machining Pro, we understand the importance of material selection and availability. We provide over 50 material choices, including metals, plastics, and even wood, to meet the diverse requirements of our customers.

Whether you need parts that require the strength of stainless steel, the lightweight properties of aluminum, or the corrosion resistance of titanium, we have the materials to bring your vision to life.

With our extensive material inventory, we ensure that you have the options you need to optimize your CNC machining projects. Our materials are sourced from reputable suppliers, guaranteeing high quality and consistency.

When you partner with Precision Machining Pro, you can rest assured that the materials used in your projects are of the highest standard. We take pride in offering a variety of materials to provide our customers with the best possible outcomes.

Surface Treatment Processes

When it comes to CNC machining, surface treatment processes play a crucial role in enhancing the final appearance and protection of machined parts. It’s important to consider CNC machining shops that offer a variety of surface treatment options to meet your specific requirements. At Worthy Hardware, we specialize in providing top-notch surface treatment processes that ensure the ultimate finish and protection for your CNC machined parts.

Bead Blasting for a Smooth Finish

One popular surface treatment process is bead blasting. Bead blasting is a method that involves using fine abrasive material to remove machining marks from the surface of the part. This process results in a smooth finish, giving the machined part a polished and refined appearance. Not only does bead blasting enhance the visual appeal of the part, but it also helps to improve surface uniformity and remove any imperfections that may affect functionality.

Anodizing for Protection and Versatility

Another surface treatment process to consider is anodizing. Anodizing involves creating an oxide layer on the surface of the part by subjecting it to an electrolytic process. This layer provides a protective barrier against corrosion and wear, making the part more durable and long-lasting. Anodizing also offers a wide range of color options, allowing you to customize the appearance of your CNC machined parts to suit your specific application or branding requirements.

“Surface treatment processes such as bead blasting and anodizing are essential for achieving the desired appearance and protection of CNC machined parts.”

By choosing a CNC machining supplier like Worthy Hardware that offers these surface treatment processes, you can ensure that your machined parts not only meet the required specifications but also have a visually appealing finish and enhanced durability. Whether you need a smooth finish or added protection, our precision machining pro will deliver outstanding results that exceed your expectations.

Final Thoughts

Choosing the right CNC machining supplier is crucial for achieving outstanding results and efficiency in your precision CNC-turning projects. By considering factors such as reliability, production capacity, technological equipment, quality control, customer feedback, on-time delivery, material selection and availability, surface treatment processes, ISO certification, and custom project requirements, you can find a reputable CNC machining company that meets your needs.

Companies like Worthy Hardware prioritize these factors and provide high-quality CNC machining services to customers worldwide. With their state-of-the-art CNC machines and advanced technological equipment, they ensure precision and accuracy in every project. Their commitment to quality control and on-time delivery ensures that your machining requirements are met with utmost satisfaction.

Whether you need small-batch machining or mass production, Worthy Hardware has the production capacity to handle your project requirements. Their wide range of material options, including metals, plastics, and wood, allows for flexibility and customization. With their expertise in surface treatment processes like bead blasting and anodizing, they provide the ultimate finish and protection for your CNC machined parts. Trust Worthy Hardware as your Precision Machining Pro for all your CNC machining needs.

FAQ

What factors should I consider when choosing a CNC machining supplier for precision CNC turning needs?

When choosing a CNC machining supplier, it’s crucial to consider factors such as reliability, production capacity, technological equipment, quality control, customer feedback, on-time delivery, material selection and availability, surface treatment processes, ISO certification, and custom project requirements.

How important is reliability when choosing a CNC machining supplier?

Reliability is a crucial factor to consider when choosing a CNC machining supplier. It’s important to select a manufacturer that offers durable and reliable CNC machines to avoid frequent repairs and ensure a long-term partnership.

What should I know about the production capacity of a CNC machining supplier?

Understanding the production capacity of a CNC machining supplier is essential. It’s important to choose a company that matches your production needs, whether it’s small-batch machining or mass production.

How does the quality of CNC machining tools impact the final products?

The quality of CNC machining tools used by a manufacturer can greatly impact the precision and quality of the final products. It’s important to choose a CNC machining shop that uses high-quality, up-to-date technological equipment and machinery.

How does quality control play a role in CNC machining services?

Quality control is a crucial aspect of CNC machining services. Choosing a CNC machining company that maintains strict quality control throughout the production process ensures that each machined part meets the required standards.

Why should I consider customer feedback when selecting a CNC machining supplier?

Customer feedback is a valuable source of information when selecting a CNC machining supplier. It’s important to consider the experiences of previous and current clients to assess the trustworthiness and reputation of a machining shop.

How important is on-time delivery in CNC machining projects?

Timely delivery is crucial for any CNC machining business. Delays in the machining process can hurt supply and demand. Look for CNC machining companies that offer shorter lead times and fast delivery of machined parts.

Why is material selection and availability important in CNC machining?

The availability of a wide range of materials is important when choosing a CNC machining shop. Look for companies that offer a variety of materials such as stainless steel, aluminum, titanium, and copper.

Why are surface treatment processes important in CNC machining?

Surface treatment plays a crucial role in the final appearance and protection of CNC machined parts. Consider CNC machining shops that offer surface treatment options like bead blasting and anodizing.

How can I choose the right CNC machining supplier for my needs?

By carefully evaluating factors such as reliability, production capacity, technological equipment, quality control, customer feedback, on-time delivery, material selection and availability, surface treatment processes, ISO certification, and custom project requirements, you can find a reputable CNC machining company that meets your needs.

Source Links

- https://prototool.com/cnc-tips/

- https://get-it-made.co.uk/resources/cnc-tips-and-tricks

- https://www.worthyhardware.com/news/10-tips-for-choosing-a-good-cnc-machining-suppliers/