Online machining services are where we assist customers with processing drawings, designs, and quotes. Also, develop group purchase ideas to implement savings for customers who want similar products

When it comes to precision online machining services, Precision Machining Pro is your trusted partner. We offer a comprehensive range of CNC machining services, specializing in the production of prototypes and finish products. Our team of experts utilizes advanced machining capabilities to ensure precision, accuracy, and fast turnaround times.

From the initial prototype stage to the final production of finished products, we understand the importance of delivering high-quality results. Our streamlined online process allows you to easily request a quote, upload your CAD files, and receive instant pricing. Whether you’re a startup, small business, designer, or inventor, our online machining services are optimized to meet your specific needs and bring your ideas to life.

Key Takeaways:

- Precision Machining Pro offers a comprehensive range of online machining services for prototypes and finish products.

- Our advanced machining capabilities ensure precision, accuracy, and fast turnaround times.

- We provide a streamlined online process for requesting quotes and uploading CAD files.

- Our services are optimized for startups, small businesses, designers, and inventors.

- With Precision Machining Pro, you can bring your ideas to life with efficiency and expertise.

Understanding Precision Machining and Its Evolution

Precision machining has undergone a significant evolution, transitioning from manual processes to CNC (Computer Numerical Control) machining. In manual machining, skilled machinists operated machines using turn wheels, dials, and a variety of cutting tools to remove or form metal according to engineering specifications.

This manual approach required expertise and precision, but it also had limitations in terms of speed, accuracy, and consistency. As technology advanced, CNC machining emerged as a game-changer in the manufacturing industry.

The Journey from Manual to CNC Machining

CNC machining revolutionized the way precision components are manufactured. Instead of relying on manual control, CNC machines are programmed with computer software to guide the entire machining process. This automation allows for greater precision, repeatability, and efficiency.

With the advent of CNC machining, manufacturers can produce complex parts with intricate geometries that were previously challenging or impossible to achieve. The machines can execute precise movements in multiple axes simultaneously, resulting in superior accuracy and finer detail.

CNC machining also offers the advantage of faster turnaround times. Once the program is set, the machining process can run continuously, reducing production time and increasing overall efficiency. This makes CNC machining ideal for both small-scale production runs and high-volume manufacturing.

Automation in Metal Cutting and Forming

Automation plays a crucial role in metal cutting and forming processes. CNC machines have automated features that enable precise control over cutting tools, workpiece positioning, and feed rates. This automation minimizes human error and ensures consistent results across all parts produced.

Metal cutting and forming operations, such as milling, turning, drilling, and grinding, have become faster, more accurate, and more reliable with the implementation of automation. These advancements have resulted in improved productivity, reduced waste, and enhanced overall product quality.

Automation has also enabled the integration of additional processes, such as automated tool changers and robotic handling systems. These advancements further streamline production, reduce downtime, and increase the overall production capacity of CNC machines.

The Role of Software in Modern Machining

Software plays a crucial role in modern machining operations. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software is used to create detailed digital models of parts and generate CNC programs that guide the machining process.

With CAD/CAM software, designers and engineers can visualize and simulate the manufacturing process before any physical production begins. This enhances design optimization, improves efficiency, and reduces the risk of errors or rework during production.

Furthermore, advanced software tools allow for the optimization of cutting paths, tool selection, and machine parameters, maximizing productivity and minimizing material waste. The integration of software with CNC machines enhances precision, accuracy, and overall machining capabilities.

Overall, precision machining has evolved with the introduction of CNC technology, automation, and advanced software. These advancements have revolutionized the manufacturing industry, enabling faster production, higher accuracy, and greater efficiency in metal cutting and forming processes.

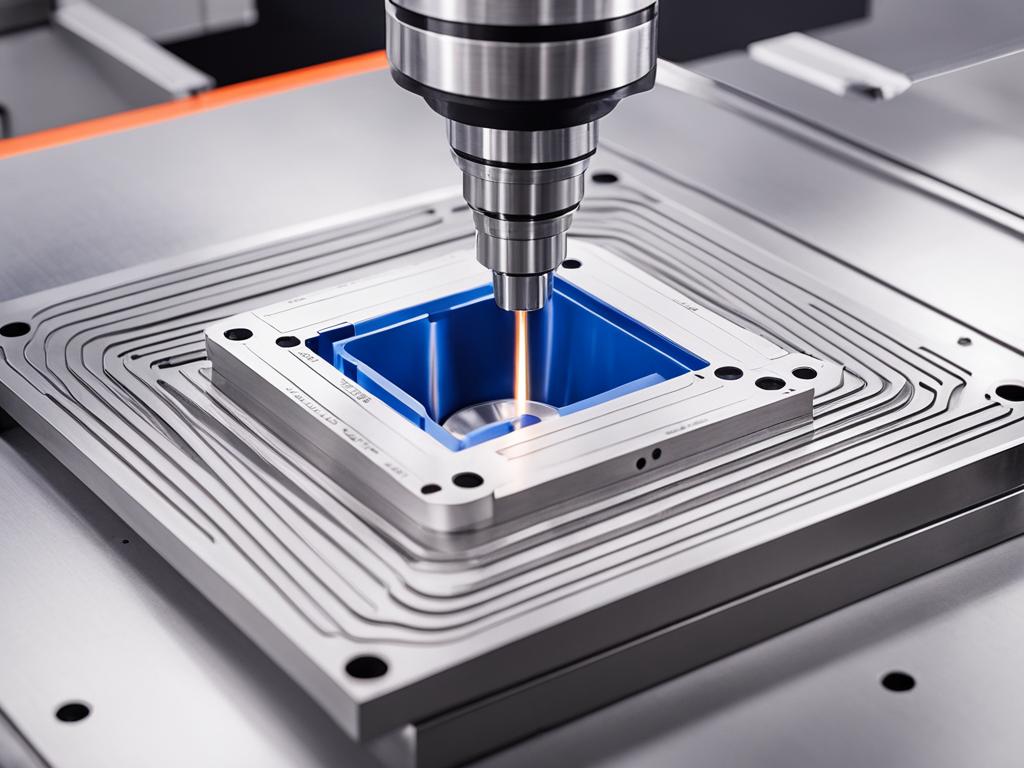

The Core of CNC Manufacturing: Advanced Capabilities

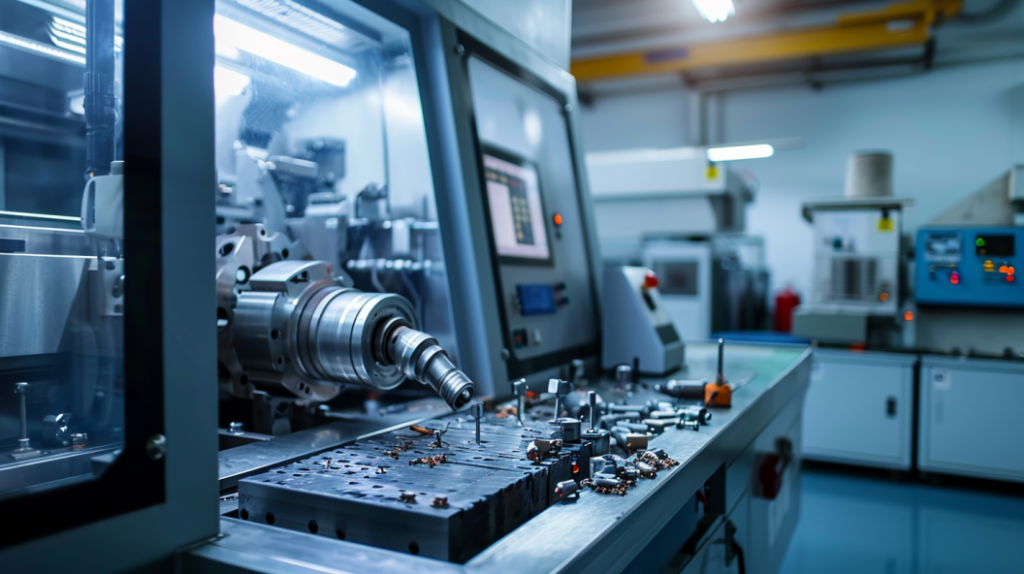

CNC manufacturing relies on advanced capabilities to achieve high-quality and efficient production. Precision Machining Pro utilizes in-house digital factories equipped with state-of-the-art CNC machines to maximize production capacity and ensure precise and consistent results. These machines have the ability to perform 3, 4, and 5-axis machining, allowing for the creation of simple and complex geometries.

With our advanced capabilities, we can handle projects of various complexities, from small-scale components to large-scale productions. Our in-house digital factories are equipped with advanced CNC machines that offer unparalleled precision and accuracy. By utilizing advanced CNC machining techniques, we can deliver high-quality parts with tight tolerances, ensuring that your designs are realized exactly as intended.

Our state-of-the-art CNC machines are capable of performing a wide range of machining operations, including milling, turning, drilling, and more. This versatility allows us to meet the specific requirements of each project and provide optimal solutions for our customers.

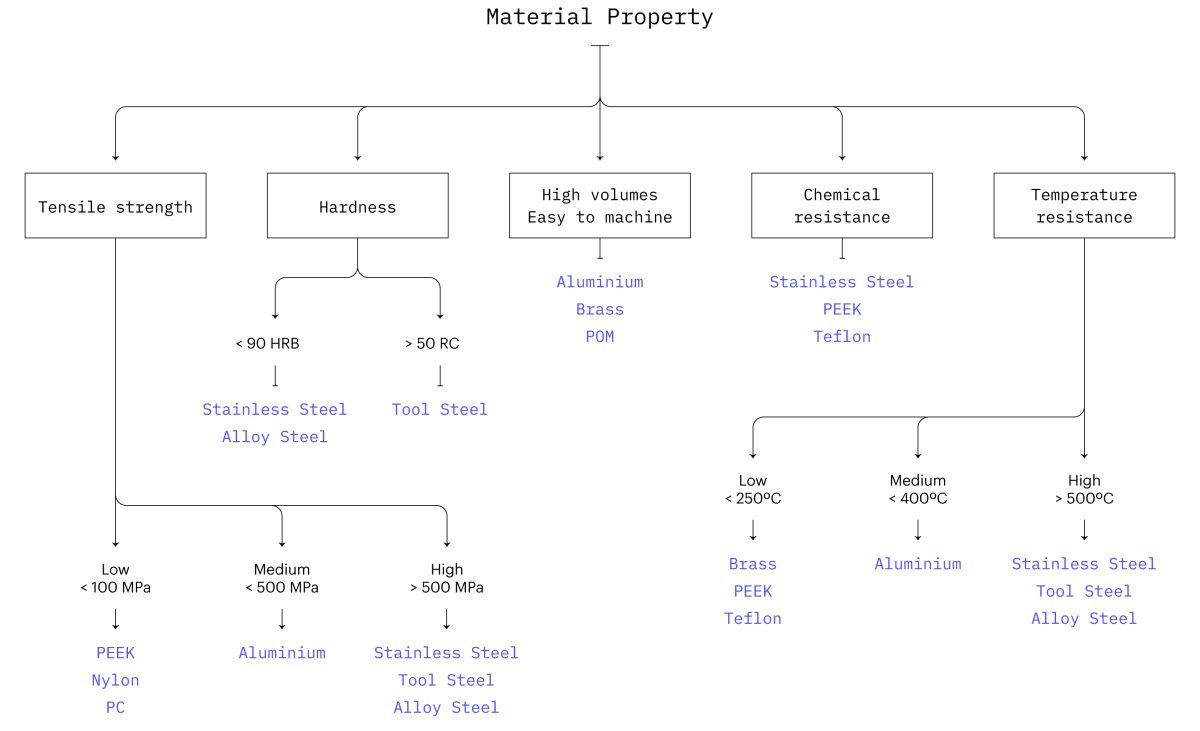

At Precision Machining Pro, we understand the importance of material selection in CNC manufacturing. That’s why we provide our customers with a wide range of material options to choose from. Whether you require metals such as aluminum, stainless steel, or titanium, or specialized materials like plastics or composites, we have the expertise and resources to accommodate your needs.

Our team of skilled engineers and technicians are well-versed in working with different materials, ensuring that your parts are machined to the highest standards. We also offer professional guidance and recommendations in material selection, taking into account factors such as strength, durability, and cost-effectiveness.

By leveraging our advanced capabilities and wide range of material options, Precision Machining Pro ensures that your CNC manufacturing projects are executed with precision, efficiency, and exceptional quality.

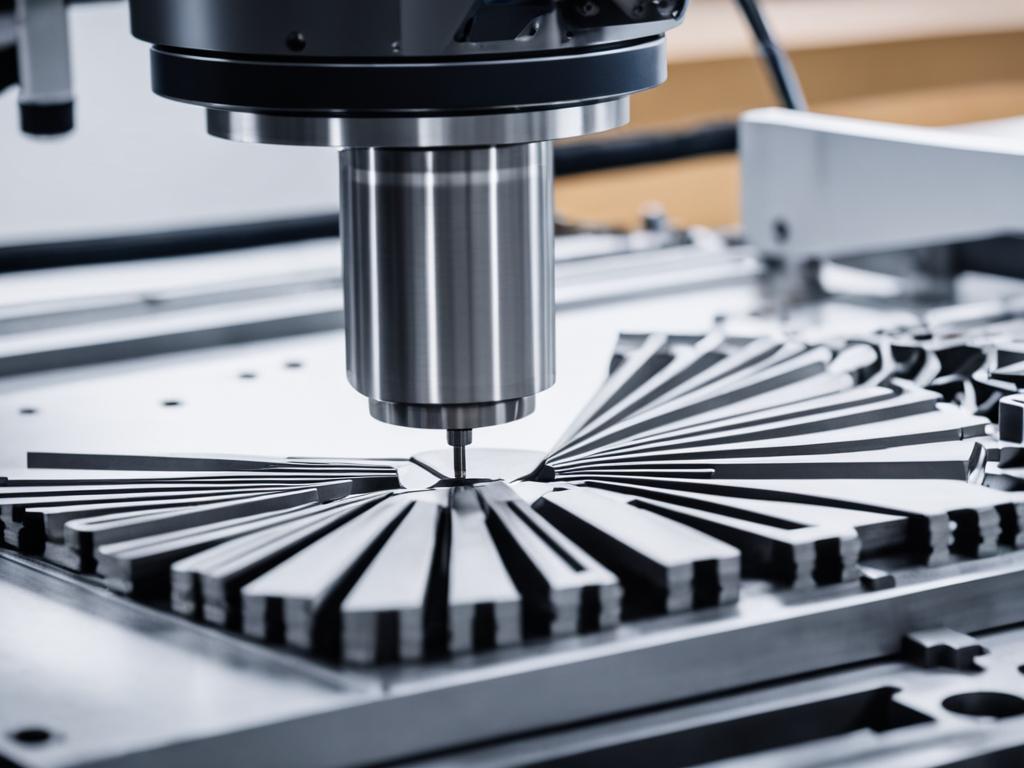

Rapid Prototyping: From Concept to Reality

Rapid prototyping is a crucial stage in the product development process, allowing designers and engineers to quickly transform their concepts into tangible prototypes. Precision Machining Pro specializes in rapid prototyping services, leveraging CNC machining technology to produce functional and accurate prototypes with fast turnaround times.

With our advanced CNC machines and expertise, we can bring your ideas to life in a matter of days. Our rapid prototyping process starts with the conversion of your 3D CAD files into machine code, which is then used to control the CNC machines and precisely shape the prototype according to your design specifications.

Whether you need a single prototype or multiple iterations to refine your design, our team at Precision Machining Pro can deliver results with speed and precision. By rapidly producing and testing prototypes, you can identify design flaws, validate functionality, and make necessary adjustments before moving forward with production.

Our rapid prototyping services are not limited to specific industries or applications. We have experience working with a wide range of materials, including metals, plastics, and composites, allowing us to accommodate various design requirements and functional needs.

At Precision Machining Pro, we understand that time-to-market is critical for the success of your project. Our streamlined process and efficient workflows ensure that your rapid prototypes are delivered on time, helping you meet tight deadlines and gain a competitive edge.

Experience the benefits of rapid prototyping with Precision Machining Pro. Contact us today to discuss your project requirements and start transforming your concepts into reality.

Custom Machining for Unique Design Requirements

Precision Machining Pro offers custom machining services to cater to your unique design requirements. Whether you need intricate components, specialized parts, or one-of-a-kind prototypes, our experienced team can deliver. We understand that every project is different, and our custom machining capabilities allow us to meet the specific needs of your design.

Upload Your CAD Files for Instant Quotes

With our streamlined online process, you can easily upload your CAD files and receive instant quotes for your custom machining projects. Our advanced software and experienced engineers ensure accurate and competitive pricing based on your design specifications. Simply upload your files, and we’ll provide you with a comprehensive quote, allowing you to make informed decisions for your project.

Material Choice and Design Flexibility

At Precision Machining Pro, we understand that material choice plays a crucial role in achieving the desired functionality and performance of your custom parts. With a wide range of materials available, including various metals and plastics, we can help you select the most suitable option for your design requirements. Additionally, our custom machining services offer design flexibility, allowing you to explore innovative solutions and bring your unique ideas to life.

Optimized Online Machining Services for Startups and Inventors

Precision Machining Pro understands the unique needs and challenges faced by startups, inventors, small businesses, and designers. Our optimized online machining services are tailored to support their innovative ideas and bring them to fruition.

The Value of Precision for Small Businesses and Designers

For small businesses and designers, precision is crucial for achieving high-quality products and maintaining a competitive edge. Our online machining services offer the precision necessary to meet the exact specifications of your designs, ensuring that every component is accurately manufactured. Whether you need prototypes, custom parts, or low-volume production, our advanced CNC machines and skilled machinists deliver exceptional precision and dimensional accuracy.

How Online Machine Shops Support Innovation

Innovation is the lifeblood of startups and inventors. Online machine shops play a vital role in supporting and nurturing this innovation by providing accessible and efficient machining services. Our online platform allows you to easily upload your CAD files and request quotes, eliminating the need for time-consuming in-person visits. By offering rapid turnaround times and competitive pricing, we empower startups and inventors to quickly iterate their designs and bring their innovative products to market.

Our commitment to precision, combined with the convenience and flexibility of our online services, makes Precision Machining Pro the ideal partner for startups, inventors, small businesses, and designers. We are dedicated to supporting your innovative ideas and helping you turn them into reality through our optimized online machining services.

The Dimensional Accuracy of Prototypes and Spare Parts

Precision Machining Pro is committed to delivering prototypes and spare parts with exceptional dimensional accuracy and precision. With the aid of our advanced CNC machines and stringent quality control processes, we ensure that every component meets the specified tolerances and design requirements.

Prototypes play a crucial role in product development, allowing designers and engineers to validate their designs and assess functionality. Our CNC machining technology enables us to create accurate and functional prototypes with fast turnaround times, empowering you to bring your ideas to life.

Spare parts are essential for maintaining and repairing machinery, ensuring the smooth operation of your equipment. Our precision manufacturing capabilities enable us to produce high-quality spare parts that perfectly match the specifications of the original components, ensuring seamless replacements.

Whether it’s prototypes or spare parts, our focus on dimensional accuracy and quality guarantees that each manufactured piece meets the highest standards. We understand the importance of precision in your projects, and our dedicated team is committed to delivering superior results with every order.

Trust Precision Machining Pro for the dimensional accuracy you need for your prototypes and spare parts.

Accelerating Your Project with Online CNC Machining

Precision Machining Pro accelerates your project timeline with our online CNC machining services. We understand that time is of the essence when it comes to product development and manufacturing. That’s why we prioritize speed and efficiency throughout every step of the process, from the moment you request a quote to the final delivery of your parts.

Fast Turnaround from Quote to Manufacture

With our streamlined online process, you can easily request a quote and receive instant pricing. We eliminate the need for back-and-forth communication and waiting periods. Our team of experts will promptly review your specifications and provide you with a comprehensive quote, ensuring a fast turnaround time that keeps your project moving forward.

Impact of Rapid Delivery on Product Development

At Precision Machining Pro, we understand that rapid delivery is crucial to the success of your product development. Our online CNC machining services enable us to produce your parts quickly and efficiently, helping you meet your project deadlines and stay ahead of the competition. With our commitment to delivering high-quality products promptly, you can accelerate your product development process and bring your ideas to market faster.

| Benefits of Online CNC Machining | Impact on Product Development |

|---|---|

| Fast turnaround times | Accelerates project timelines |

| Efficient online process | Reduces communication and waiting time |

| Prompt quote and pricing | Enables faster decision-making |

| Rapid delivery | Meets project deadlines |

| High-quality products | Ensures customer satisfaction |

| Competitive advantage | Keeps you ahead in the market |

Online Machine Shop: A Hub for CNC Turning, Milling, and More

Precision Machining Pro is an all-in-one online machine shop, providing a comprehensive range of CNC machining services to meet the diverse needs of our customers. Our capabilities include CNC turning, CNC milling, and more, enabling us to deliver high-quality precision parts and components for various industries.

With our state-of-the-art equipment and advanced machining techniques, we offer precise and efficient solutions for projects of all sizes. Whether you require complex geometries, tight tolerances, or specific material requirements, our team of experienced machinists and engineers can assist you throughout the entire manufacturing process.

By leveraging the power of online technology, we have streamlined our quoting and ordering process, allowing you to easily upload your CAD files, receive instant quotes, and track the progress of your project in real-time. Our online machine shop eliminates the need for physical visits and enables you to access our services conveniently from anywhere in the world.

At Precision Machining Pro, we prioritize quality, precision, and customer satisfaction. Our commitment to excellence and attention to detail sets us apart as a trusted partner for all your CNC machining needs. Whether you need prototypes, small production runs, or large-scale manufacturing, our online machine shop is equipped to handle your project with efficiency and expertise.

Meeting Design Challenges Through 3D CAD and Advanced Software

Precision Machining Pro excels in meeting design challenges through the utilization of 3D CAD and advanced software. Our engineers and designers are experienced in working with industry-leading software programs such as Fusion 360, SolidWorks, and Autodesk Inventor.

With 3D CAD, we can create accurate virtual models of your designs, allowing for thorough visualization and analysis before the manufacturing process begins. This helps identify any potential issues or improvements early on, saving time and resources in the long run.

Advanced software like Fusion 360, SolidWorks, and Autodesk Inventor enhances the design process by providing robust tools and features. These software programs enable us to create complex geometries, simulate real-world conditions, and optimize designs for manufacturability.

By leveraging the capabilities of 3D CAD and advanced software, Precision Machining Pro ensures that your design challenges are met with precision and efficiency. Whether it’s overcoming intricate part geometries, optimizing material usage, or improving overall functionality, our team is equipped to deliver innovative solutions that meet your exact specifications.

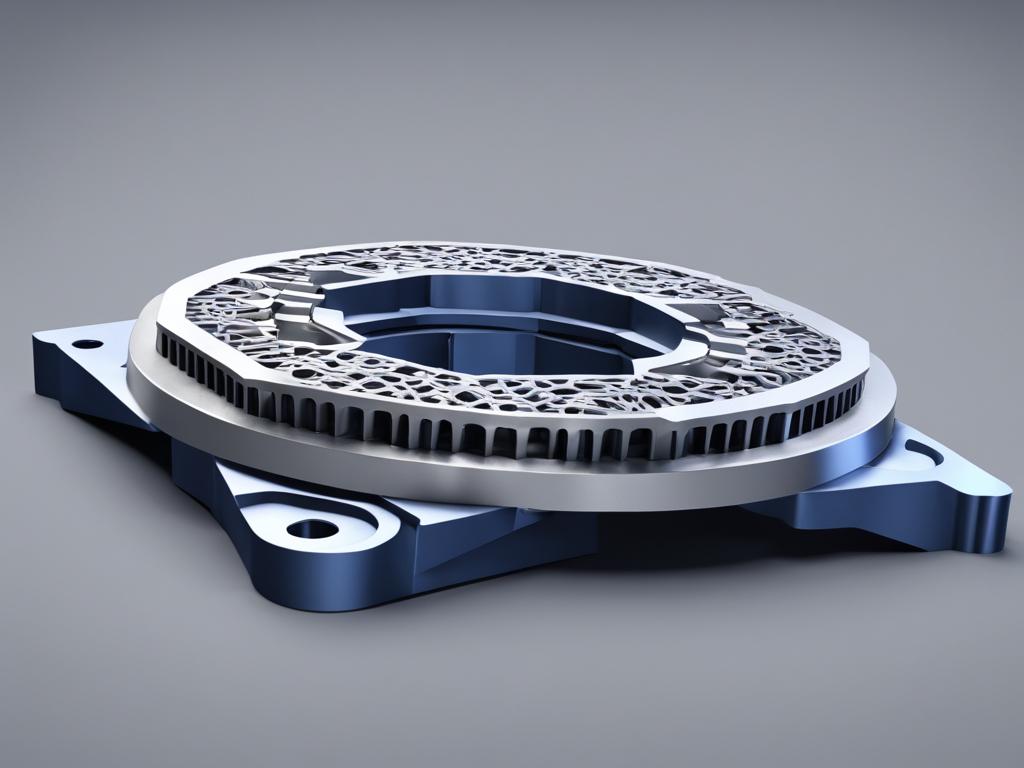

Low-Volume Production Batches and Manufacturing Jigs & Fixtures

Precision Machining Pro specializes in catering to low-volume production batches, offering efficient and cost-effective solutions for small to medium-scale manufacturing. Whether you require a small batch of custom parts or a limited production run, our capabilities and expertise enable us to meet your unique requirements.

When it comes to low-volume production, our team understands the importance of precision and consistency. We utilize advanced manufacturing jigs and fixtures to ensure accurate and repeatable results in every production cycle. These custom-made tools provide the necessary support and guidance during the manufacturing process, minimizing errors and optimizing efficiency.

With our state-of-the-art manufacturing equipment and skilled technicians, we are able to produce high-quality components with tight tolerances, even in low-volume production runs. Our streamlined processes and quality control measures guarantee that each part meets your exact specifications, delivering the performance and reliability you expect.

Whether you are launching a new product, conducting market testing, or catering to a niche market, Precision Machining Pro is your trusted partner for low-volume production. Our commitment to excellence and customer satisfaction ensures that your manufacturing needs are met with precision, efficiency, and cost-effectiveness.

Quality Assurance: Inspected Before Shipment

Precision Machining Pro understands that ensuring the highest quality of products is essential for customer satisfaction. That’s why we have established stringent quality assurance protocols to meticulously inspect every component before shipment. Our dedicated team of quality control experts meticulously examines each part to guarantee that they meet the exacting standards of excellence that our customers expect.

Adherence to ISO Standards in Precision Machining

At Precision Machining Pro, we are committed to upholding the highest industry standards in precision machining. Our operations strictly adhere to ISO standards, ensuring that our manufacturing processes are carried out with precision and accuracy. By maintaining compliance with these internationally recognized benchmarks, we demonstrate our dedication to delivering exceptional quality and reliability in every product we produce.

Implementing Quality Checks Throughout Manufacturing

We believe that quality checks are crucial at every stage of the manufacturing process. To achieve this, we have incorporated a comprehensive system of quality checks throughout our production line. From initial material inspection to final assembly, our experienced technicians perform meticulous quality checks to ensure that each component meets our exacting standards. These checks include dimensional accuracy verification, functionality testing, and visual inspections, among others, to guarantee the excellence of our products.

Conclusion

At Precision Machining Pro, we are committed to helping you reach the pinnacle of machining efficiency throughout every stage of your product development process. From the initial prototype to the final finished product, our advanced online machining services and streamlined processes ensure that your design specifications are realized with precision and accuracy.

With our state-of-the-art CNC machines and experienced team, we prioritize speed, efficiency, and quality to meet your project deadlines. Our in-house digital factories equipped with advanced capabilities allow us to offer a wide range of material options and perform both simple and complex machining tasks.

Whether you are a startup, inventor, small business, or designer, our optimized online machining services cater to your unique needs. We understand the challenges you face and are here to support your innovative ideas and bring them to life. Trust Precision Machining Pro as your reliable partner for all your precision CNC machining needs.

FAQ

What services does Precision Machining Pro offer?

Precision Machining Pro offers a comprehensive range of online machining services, including CNC turning, CNC milling, rapid prototyping, and custom machining. We also provide low-volume production batches and manufacturing jigs & fixtures.

How do I request a quote for machining services?

To request a quote, simply upload your CAD files on our website using formats such as STEP, IGES, or X_T. Our system will generate an instant quote based on your design, material choice, and order quantity.

What CAD software formats does Precision Machining Pro accept?

Precision Machining Pro accepts CAD file formats such as Fusion 360, SolidWorks, and Autodesk Inventor. You can easily upload your CAD files in these formats for our machining services.

Does Precision Machining Pro support rapid prototyping?

Yes, Precision Machining Pro specializes in rapid prototyping services. Leveraging our CNC machining technology, we can produce functional and accurate prototypes with fast turnaround times.

What industries does Precision Machining Pro cater to?

Precision Machining Pro caters to a wide range of industries, including startups, small businesses, designers, inventors, and manufacturers who require precision machining solutions.

Does Precision Machining Pro ensure the quality of manufactured parts?

Yes, Precision Machining Pro ensures the dimensional accuracy and precision of all prototypes and spare parts manufactured. Our advanced CNC machines undergo quality checks and are inspected before shipment.

What are the benefits of using Precision Machining Pro’s online machining services?

By using Precision Machining Pro’s online machining services, you can benefit from streamlined processes, fast turnaround times, and access to advanced CNC capabilities. Our services are optimized for startups, small businesses, designers, and inventors to bring their ideas to life efficiently.

Can Precision Machining Pro handle low-volume production batches?

Yes, Precision Machining Pro can cater to low-volume production batches, providing efficient and cost-effective solutions for small to medium-scale manufacturing.

Does Precision Machining Pro adhere to quality standards?

Yes, Precision Machining Pro adheres to ISO standards in precision machining. We implement rigorous quality checks throughout the manufacturing process to ensure excellence in our products.

What machining capabilities does Precision Machining Pro offer?

Precision Machining Pro offers a wide range of machining capabilities, including CNC turning, CNC milling, 3-axis, 4-axis, and 5-axis machining. Our capabilities enable us to create simple and complex geometries.