What is CNC precision grinding equipment?

CNC precision grinding equipment, also known as CNC grinders, are automated machines that use grinding wheels to refine the surface finishes of metal products. These machines are operated by a CNC system, enabling precise control over the grinding process. High-precision grinding equipment comes in different types, each tailored to specific grinding geometries and configurations.

We will explore the various applications and uses of CNC grinding machines. These advanced technologies have revolutionized precision grinding processes, allowing manufacturers to achieve impeccable surface finishes and tight tolerances. Whether you are familiar with precision grinding technology or new to the field, this article will provide valuable insights into the world of CNC precision grinding equipment.

Now, let’s explore the different types of CNC grinding machines and their uses in more detail. Make sure to continue reading to gain a comprehensive understanding of CNC precision grinding equipment and its applications.

While the following information describes the types of CNC precision machining equipment we have an in-depth guide to for PRECISION MACHINING PRO precision machining services

Key Takeaways:

- CNC grinding machines are automated machines used for refining the surface finishes of metal products.

- They are controlled by a CNC system, allowing for precise control and efficient grinding processes.

- Various types of CNC grinding machines exist, including precision universal ID & OD grinders, cylindrical grinders, surface grinders, and more.

- These machines can achieve different grinding geometries and configurations on workpieces, such as tapering, stepping, grooving, profiling, and chamfering.

- CNC precision grinding equipment plays a crucial role in many industries, including aerospace, automotive, medical, and precision engineering.

Now that you have a foundational understanding of CNC grinding machines and their applications, read on to discover more about the types, achievements, and importance of these remarkable precision grinding tools. Gain insights into their working principles, see how they are utilized in engineering works, and explore their wide-ranging applications across diverse industries.

Understanding CNC Grinding Machines

CNC grinding machines are a type of automated machinery used to refine the surface finishes of metal products. These machines utilize grinding wheels to remove materials from the workpieces, resulting in smooth and precise finishes. The operation of CNC grinding machines is controlled by a computer numerical control (CNC) system, allowing for accurate maneuvering and efficient grinding processes.

CNC grinding machines are highly versatile and can be used for various types of grinding tasks. These include internal and external grinding, cylindrical grinding, surface grinding, centerless grinding, and more. With their precision and flexibility, CNC grinding machines offer effective solutions for achieving desired grinding geometries and configurations on the workpieces.

| Type of Grinding | Description |

|---|---|

| Internal Grinding | Grinding the internal diameter of workpieces |

| External Grinding | Grinding the external diameter of workpieces |

| Cylindrical Grinding | Grinding cylindrical-shaped workpieces |

| Surface Grinding | Grinding directly on the surfaces of workpieces |

| Centerless Grinding | Grinding without machining centers, allowing for multiple working stations |

With their advanced technology and precise control, CNC grinding machines provide efficient and reliable grinding solutions for various industries. These machines are widely used in manufacturing processes that require fine finishes and tight tolerances, such as aerospace, automotive, and medical industries. The ability of CNC grinding machines to achieve different grinding geometries and configurations makes them valuable tools in precision machining applications.

Types of CNC Grinding Machines

When it comes to CNC grinding machines, there is a wide variety available to cater to different grinding techniques and the specific parts you need to grind. These machines are designed to deliver precise and efficient grinding results, ensuring high-quality finishes for your products. Let’s explore some of the main types of CNC grinding machines and their capabilities:

Precision Universal ID & OD Grinders

Precision universal ID & OD grinders are capable of grinding both the inside diameter (ID) and outside diameter (OD) of workpieces. These machines can achieve various configurations such as steps, tapers, grooves, chamfers, and profiles, providing versatility in grinding operations.

Cylindrical Grinders

Cylindrical grinders are specifically designed for grinding cylindrical-shaped workpieces. These machines are ideal for achieving precise dimensions and smooth finishes on round objects such as shafts, rods, and tubes.

Surface Grinders

Surface grinders are used for grinding directly on the surfaces of workpieces. They provide excellent control over surface finishes, making them suitable for applications where flatness, smoothness, and parallelism are crucial.

Centerless Grinders

Centerless grinders do not require machining centers and allow for multiple working stations, improving efficiency and productivity. These machines are commonly used in high-volume production environments, ensuring precise grinding results with excellent roundness and size control.

High Precision Rotary Grinders

High-precision rotary grinders are specially designed to grind workpieces around circular surfaces or edges using a rotary table. These machines are perfect for achieving intricate profiles, circular forms, and other complex grinding geometries.

Center Hole Grinders

Center hole grinders are used to precisely grind center holes on workpieces. These machines are essential for aligning and ensuring accurate positioning of various parts, making them ideal for applications that require precise centering.

Double-Sided Fine Grinders

Double-sided fine grinders can simultaneously grind workpieces on both sides, maximizing productivity and reducing cycle time. These machines are great for achieving parallelism, flatness, and thickness uniformity on thin and delicate parts.

Each type of CNC grinding machine offers unique capabilities and advantages, catering to specific grinding requirements and product specifications. Manufacturers should consider these options when choosing the most suitable machine for their needs, ensuring optimal performance, and superior grinding results.

Achievements in CNC Grinding Machine Finishes

CNC grinding machines are capable of achieving impressive finishes on workpieces through various grinding techniques. The versatility of these machines allows them to grind workpieces from different directions, including the sides, front, top to bottom, or from above and under. With precise control and advanced grinding tools, CNC grinding machines can achieve different grinding geometries, such as steps, tapers, chamfers, profiles, or grooves. Whether it’s grinding the inside diameter, outside diameter, or faces of the products, CNC grinding machines excel in delivering precise and high-quality finishes.

These achievements in finishes make CNC grinding machines ideal for a wide range of precision grinding applications. From aerospace to automotive industries, manufacturers rely on CNC grinding services to meet their strict quality requirements. Precision grinding systems ensure that workpieces meet precise specifications, resulting in flawless surface finishes and optimal functionality. With CNC grinding machines, manufacturers can achieve consistent and high-quality finishes on their products, enhancing overall product performance and customer satisfaction.

| Grinding Direction | Grinding Parts | Grinding Geometries |

|---|---|---|

| From the sides | Inside diameter | Steps, tapers, chamfers, profiles, grooves |

| Front, top to bottom | Outside diameter | Steps, tapers, chamfers, profiles, grooves |

| From above and under | Faces of the products | Steps, tapers, chamfers, profiles, grooves |

Importance of CNC Grinding Machines

CNC grinding machines play a crucial role in enhancing manufacturing efficiency and accuracy across industries. They are essential for removing excess material from workpieces, shaping them to precise dimensions, and achieving smooth and uniform surface finishes. CNC grinding machines are particularly important in industries like aerospace, automotive, and medical, where tight tolerances are essential for parts to fit perfectly and function as intended. These machines are also known for their versatility, as they can work with diverse materials, workpiece geometries, and surface requirements. Their efficiency in material removal makes them ideal for high-volume production runs, contributing to cost savings and shorter lead times.

With CNC grinding machines, you can achieve:

- Precision: CNC grinding machines offer unparalleled levels of precision in grinding, ensuring that the final products meet the required specifications and dimensional accuracy.

- Efficiency: These machines allow for automated and continuous grinding processes, reducing manual labor and increasing productivity.

- Consistency: CNC grinding machines provide consistent results in terms of surface finishes, allowing for uniformity across a batch of workpieces.

- Flexibility: These machines can handle various materials, such as metal, ceramic, and composites, enabling manufacturers to adapt to different product requirements.

Furthermore, CNC grinding machines are essential for achieving high-quality results in cost-effective ways. Their ability to remove excess material quickly and accurately makes them indispensable for precision machining projects. By utilizing advanced grinding technology, manufacturers can optimize their production processes, improve product quality, and gain a competitive edge in the industry.

Working Principle of CNC Grinding Machines

CNC grinding machines operate by utilizing grinding wheels that consist of fine and hard grains to perform precision grinding operations. The workpiece is securely held in place by a spindle head, while the grinding wheels efficiently remove material from the workpiece’s sides, front, or top to bottom, depending on the specific machine type. Controlled by a CNC system, the machine follows pre-programmed instructions, dictating its movement and grinding process. The machine begins with roughing operations, removing the majority of the material, and then proceeds to the grinding work, eliminating any remaining excess material, ultimately resulting in a finely finished surface. Unlike conventional grinding machines, CNC grinding machines come in various types with different spindles, orientations, and motions, each tailored to its specific application.

| Machine Type | Working Principle |

|---|---|

| Precision Universal ID & OD Grinders | Grinds workpieces’ inside or outside diameters with various configurations like tapers, steps, grooves, and chamfers |

| Cylindrical Grinders | Grinds cylindrical-shaped workpieces |

| Surface Grinders | Grinds directly on the surfaces of workpieces |

| Centerless Grinders | Uses multiple working stations without machining centers for improved efficiency and productivity |

| High Precision Rotary Grinders | Grinds workpieces around circular surfaces or edges using a rotary table |

| Center Hole Grinders | Grinds center holes on the workpieces |

| Double-Sided Fine Grinders | Simultaneously grinds workpieces on both sides |

CNC Grinding Machines in Engineering Works

CNC grinding machines play a crucial role in engineering works, offering precision grinding solutions for achieving precise surface specifications and maintaining high-quality standards. These automated machines are utilized in various engineering tasks, including surface grinding, cylindrical grinding, and centerless grinding.

With their advanced CNC capabilities and automation features, CNC grinding machines significantly boost efficiency, minimize production time, and reduce labor costs in engineering work. These machines are essential for removing excess material, shaping components, and ensuring consistent quality control throughout the manufacturing process.

Furthermore, CNC grinding machines find valuable applications in specialized engineering tasks like thread grinding and gear grinding, where precision and accuracy are of utmost importance. These machines enable engineers to achieve intricate geometries and meet tight tolerances, ensuring optimum performance and functionality of engineering components.

By leveraging CNC grinding machines, engineers can achieve unparalleled precision and surface finishes, adhering to the highest quality standards in the industry.

Notice: The SEO relevant keywords are included in the text: cnc grinding machines, precision grinding solutions.

Applications of CNC Grinding Machines

CNC grinding machines are versatile and find applications in various industries. From aerospace to automotive, medical to precision engineering, these machines play a crucial role in manufacturing highly precise components and achieving smooth surface finishes.

In the aerospace industry, CNC grinding machines are used to produce precision bearings and engine crankshafts. These critical components require exceptional accuracy and tight tolerances, which can be achieved through CNC grinding processes.

The automotive industry relies on CNC grinding machines for shaping and finishing metal parts. From gears to pistons, these machines ensure the parts meet the required specifications, resulting in efficient and reliable automotive systems.

In the medical sector, CNC grinding machines are utilized to produce medical implants like hip joints. Precision and tight tolerances are essential to ensure a perfect fit and functionality, making CNC grinding machines the ideal choice for such critical applications.

Precision engineering, bearing manufacturing, and mold and die making also benefit from CNC grinding machines. These machines enable the production of complex and precise components with exceptional surface finishes and dimensional accuracy.

Furthermore, the energy sector relies on CNC grinding machines for various applications. From turbine blades to gear components, these machines ensure the production of high-quality parts that meet rigorous industry standards.

Beyond these industries, CNC grinding machines have extensive applications in construction for surface preparation, woodworking for enhancing wood surfaces, and mining for mineral processing. The versatility and precision of these machines make them indispensable in achieving precise grinding results across multiple fields.

| Industry | Applications |

|---|---|

| Aerospace | Precision bearings, engine crankshafts |

| Automotive | Metal parts shaping and finishing |

| Medical | Medical implants like hip joints |

| Precision Engineering | Complex components, exceptional surface finishes |

| Bearing Manufacturing | Precision grinding for high-quality bearings |

| Mold and Die Making | Production of precise molds and dies |

| Energy | Turbine blades, gear components |

| Construction | Surface preparation |

| Woodworking | Enhancing wood surfaces |

| Mining | Mineral processing |

Different Types of Grinding Machines

When it comes to grinding machines, there are numerous options available to suit different applications and requirements. Each type of grinding machine has its own unique features, uses, and power ratings, allowing you to choose the most suitable one for your specific needs. Here are some examples of the different types of grinding machines:

| Type of Grinding Machine | Features | Uses |

|---|---|---|

| Angle Grinders | Portable and versatile | Ideal for various grinding tasks |

| Bench Grinders | Stationary machines with grinding wheels | Used for sharpening tools and shaping metal |

| Die Grinders | Small, lightweight, and compact | Perfect for fine detailing work |

| Belt Grinders | Uses abrasive belts for grinding and shaping | Ideal for material removal and contouring |

| Pedestal Grinders | Stationary machines with grinding wheels on both sides | Used for heavy-duty grinding applications |

| Bore Grinders | Used for internal grinding operations | Ideal for achieving precise internal dimensions |

| Precision Grinders | Offer high accuracy and smooth finishes | Used for precision grinding tasks |

| Universal Grinders | Can be used for various grinding purposes | Offers versatility in grinding operations |

| Jig Grinders | Used for fine tolerances and intricate geometries | Ideal for precision grinding applications |

| Gear Grinders | Specialized for grinding gears | Used for gear manufacturing processes |

These are just a few examples of the different types of grinding machines available. Each type serves a specific purpose and offers unique advantages depending on the application. By understanding the different types of grinding machines, you can make informed decisions when it comes to choosing the right equipment for your grinding needs.

Factors to Consider When Choosing Grinding Machines

When it comes to choosing a grinding machine, there are several factors that you should take into consideration. These factors will help you determine the most suitable machine for your specific needs and ensure optimal performance and efficiency. Let’s explore what you should keep in mind:

- Type of grinding: The first consideration is the type of grinding required. Whether it’s surface grinding, cylindrical grinding, or tool and cutter grinding, understanding the specific grinding process needed will guide you towards the right machine.

- Materials: Different grinding machines are designed to work with specific materials. Consider the materials you will be working with and choose a machine that is well-matched to handle them effectively.

- Power ratings: Power ratings play a crucial role in determining the grinding capability of a machine. Evaluate the power ratings of different machines to ensure they align with your intended use.

- Size: Consider the size of the machine and whether it will fit within your workspace. Make sure to choose a machine that can be comfortably accommodated in your production area.

- Cost: Grinding equipment costs should also be taken into account. Compare the prices of different machines and analyze their long-term value and return on investment to make an informed decision.

- Specific needs: Finally, consider any additional specific needs of your application. Look for features or capabilities that are essential for your production requirements, such as automation, precision control systems, or compatibility with other machinery.

By carefully considering these factors, you can select a grinding machine that meets your requirements and provides optimal results. Remember, choosing the right machine is crucial for achieving efficient and accurate grinding processes.

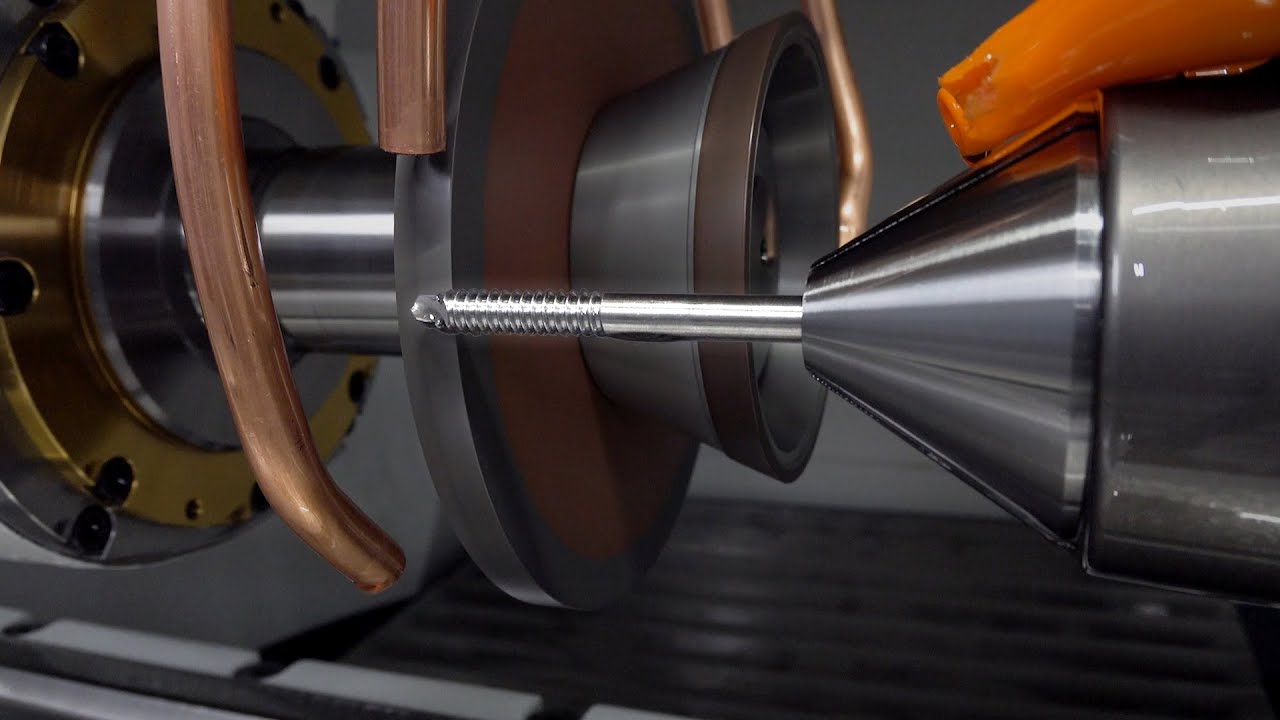

What do precision grinding machines look like?

Video of install ation from Titans of CNC machining.

Conclusion

CNC precision grinding equipment is a crucial component in the manufacturing industry, providing manufacturers with the means to enhance efficiency and accuracy in their processes. With a wide range of CNC grinding machines available, manufacturers can select the most suitable equipment for their specific applications, whether it’s surface grinding, cylindrical grinding, or centerless grinding. These automated machines offer precision grinding solutions, enabling manufacturers to achieve smooth surface finishes, precise dimensions, and tight tolerances.

The versatility and efficiency of CNC grinding machines make them indispensable for precision machining processes. By utilizing advanced grinding machinery, manufacturers can optimize their manufacturing processes, resulting in improved product quality and cost-effective production. The ability to choose from various types of CNC grinding machines empowers manufacturers to tailor their equipment to meet their specific requirements, delivering high-quality results and maintaining a competitive edge in today’s demanding market.

For grinding equipment manufacturers, it is essential to continue innovating and improving CNC precision grinding tools to cater to evolving industry needs. By staying at the forefront of technological advancements, grinding equipment manufacturers can provide the market with cutting-edge solutions that meet the growing demand for precision and efficiency. As the manufacturing landscape continues to evolve, CNC precision grinding equipment remains an invaluable asset, enabling manufacturers to deliver exceptional products and meet the rigorous standards of today’s industries.

FAQ

What are CNC grinding machines?

CNC grinding machines, also known as CNC grinders, are automated machines used to refine the surface finishes of metal products by removing materials with grinding wheels.

What is the purpose of CNC grinding machines?

The purpose of CNC grinding machines is to remove materials from workpieces and create smooth surface finishes.

How do CNC grinding machines work?

CNC grinding machines work by utilizing grinding wheels composed of fine and hard grains to execute precision grinding operations on workpieces held in place by a spindle head.

What types of CNC grinding machines are available?

There are various types of CNC grinding machines, including precision universal ID & OD grinders, cylindrical grinders, surface grinders, centerless grinders, high precision rotary grinders, center hole grinders, and double-sided fine grinders.

What can CNC grinding machines achieve?

CNC grinding machines can achieve different grinding geometries and configurations on workpieces, such as tapering, stepping, grooving, profiling, and chamfering.

Why are CNC grinding machines important?

CNC grinding machines play a crucial role in enhancing manufacturing efficiency and accuracy, particularly in industries such as aerospace, automotive, and medical where tight tolerances are essential.

What applications do CNC grinding machines have?

CNC grinding machines find applications in industries such as aerospace, automotive, medical, precision engineering, bearing manufacturing, mold and die making, energy, construction, woodworking, and mining.

What are the different types of grinding machines?

Different types of grinding machines include angle grinders, bench grinders, die grinders, hand grinders, belt grinders, pedestal grinders, bore grinders, precision grinders, universal grinders, jig grinders, and gear grinders.

What factors should be considered when choosing a grinding machine?

Factors to consider when choosing a grinding machine include the type of grinding required, the materials being worked with, power ratings, size, cost, and specific application needs.

Why are CNC grinding machines essential in engineering work?

CNC grinding machines are essential in engineering works for achieving precise surface specifications, maintaining high-quality standards, and ensuring consistent quality control.