At Precision Machining Pro, we specialize in providing expert precision machining services with quick turnaround times. Our state-of-the-art facility, located in Southbridge, MA, is equipped with the latest 3 and 5 axis CNC machines and cutting-edge CAM software, allowing us to deliver high-quality precision machining solutions.

With our advanced CNC machining capabilities, we can produce prototypes, patterns, and short-run production parts with exceptional precision and tight tolerances. Our team of skilled machinists can work with a variety of materials, including aluminum, steel, plastic, and composites, ensuring that we can meet the unique needs of every project.

At Precision Machining Pro, we understand the importance of quick turn and rapid turnaround times in the manufacturing industry. That’s why our facility is optimized for efficient production and timely delivery of your parts. You can rely on us to deliver your machined components on time, every time.

Key Takeaways:

- Precision Machining Pro offers expert precision machining services with quick turnaround times.

- We utilize state-of-the-art 3 and 5 axis CNC machines and cutting-edge CAM software.

- We can work with a variety of materials, including aluminum, steel, plastic, and composites.

- Our facility in Southbridge, MA is optimized for quick turn and rapid turnaround jobs.

- You can trust us to deliver high-quality precision machined parts on time.

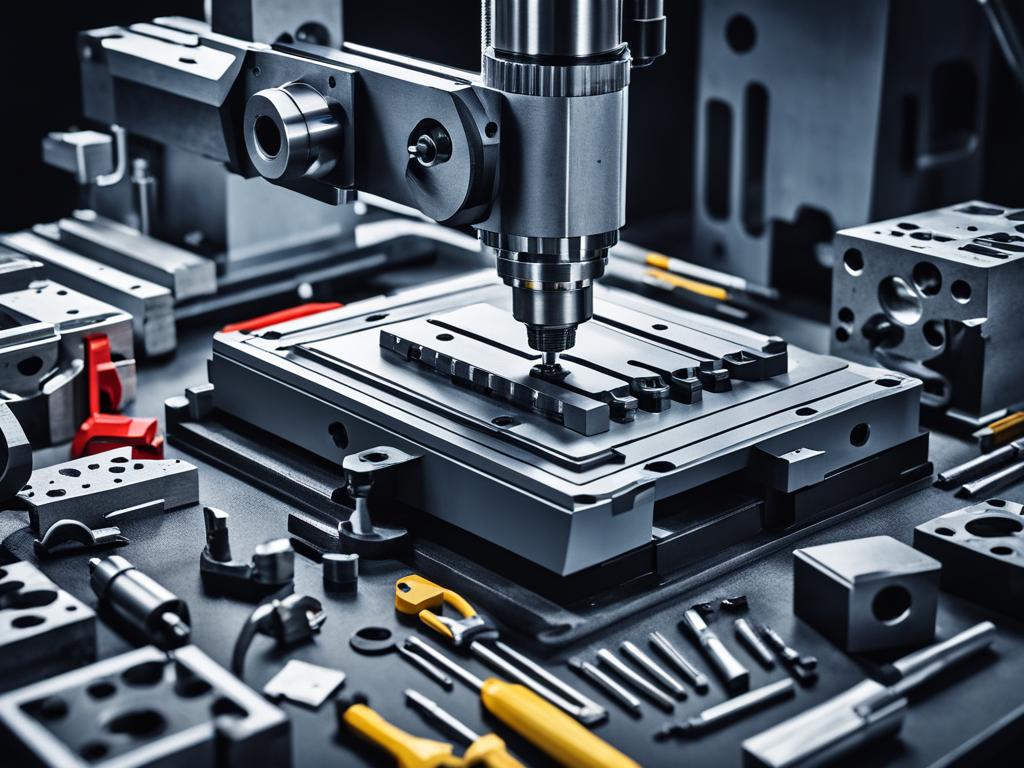

CNC Milling

At Precision Machining Pro, we specialize in CNC milling, offering you precise manufacturing and repeatable results. Our state-of-the-art CNC milling machines are equipped with 10 different models, designed to meet your specific needs. With our advanced technology and expertise, we provide quick turnaround times for rapid prototyping and low-to-high volume production runs.

Our CNC milling machines are perfect for:

- Rapid prototyping: We can quickly produce one-piece prototypes to validate your design concepts and make any necessary iterations.

- Low-to-high volume production: Whether you need a small batch or a large-scale production run, our CNC milling machines can handle your project efficiently.

Our experienced team has the capability to handle customer tooling, ensuring flexibility and reliability throughout the entire machining process. With our precision CNC milling machines, you can expect high-quality parts with tight tolerances and consistent results.

Take a look at our CNC milling capabilities:

| Capability | Description |

|---|---|

| High precision | Our CNC milling machines offer unmatched precision, allowing us to achieve tight tolerances and produce intricate designs. |

| Efficient production | With our advanced technology and skilled operators, we optimize production processes to deliver fast turnaround times without compromising quality. |

| Material versatility | We can work with a wide range of materials, including aluminum, steel, plastics, and composites, ensuring that we can fulfill your specific material requirements. |

| Cost-effective | Our CNC milling services offer cost-effective solutions for both prototyping and production, minimizing material waste and reducing overall manufacturing costs. |

Trust Precision Machining Pro for all your CNC milling needs. Our expertise and cutting-edge technology enable us to deliver high-quality parts for a wide range of industries. Contact us today or visit our website at precisionmachiningpro.com to learn more about our CNC milling services!

CNC Turning

At Precision Machining Pro, we offer advanced CNC turning services to meet your machining requirements. Our state-of-the-art CNC turning machines with milling operation provide optimal efficiency by eliminating costly setup time.

Equipped with multi-axis CNC lathes and live tooling, our machines are capable of performing a wide range of operations, including facing, threading, knurling, drilling, and taper turning. This versatility allows us to produce complex components with precision and accuracy.

Whether you need intricate threading on a custom part or complex contours for your project, our CNC turning capabilities ensure that we can deliver high-quality machined components that meet your specifications.

With our commitment to cutting-edge technology and skilled machinists, Precision Machining Pro is your trusted partner for CNC turning services. Contact us today to discuss your project requirements and experience precision machining at its best.

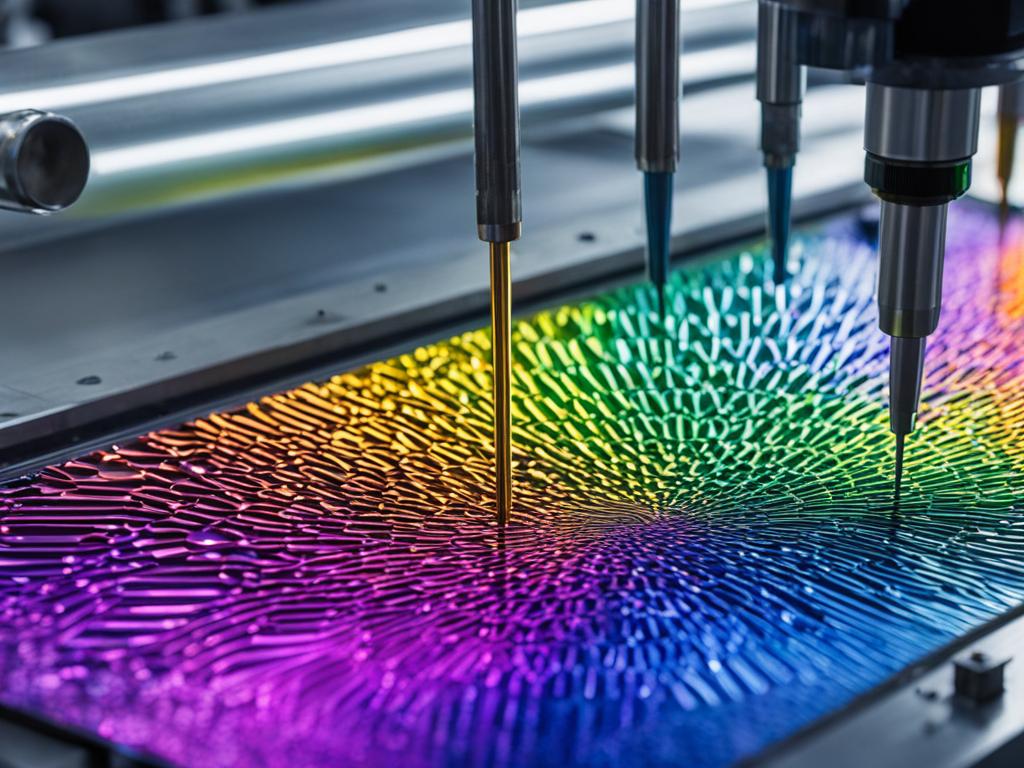

CNC 5-Axis Machining

At Precision Machining Pro, we leverage the power of CNC 5-axis machining to tackle complex geometries and achieve unparalleled precision. Our advanced 5-axis CNC machines minimize machine setups and unlock the potential for intricate contouring and machining processes.

With our cutting-edge dual-axis trunnion table, we can effortlessly position parts at multiple angles, enabling 5-axis machining or full simultaneous 5-axis motion. This capability not only enhances productivity but also ensures the efficient production of parts with intricate designs and complex features.

Whether it’s for aerospace components, automotive parts, or medical devices, our CNC 5-axis machining capabilities allow us to meet the demands of even the most challenging projects. With precision and efficiency at the forefront, we deliver exceptional results that surpass expectations.

Rapid CNC Tooling Service

At Precision Machining Pro, we provide a rapid CNC tooling service that allows us to create hard tooling with exceptional precision and efficiency. Our state-of-the-art facility and skilled team enable us to work with various materials, including hardened or pre-hardened steel and aluminum, to meet your specific tooling needs.

Whether you require tooling for prototypes, custom projects, or low-to-high volume production, we have the capabilities to deliver. We understand the importance of quick turnaround times in today’s fast-paced manufacturing industry, and we pride ourselves on our ability to meet tight deadlines without compromising quality.

When you choose our rapid CNC tooling service, you can expect:

- Hard Tooling: We use high-quality materials to create durable tooling that can handle the demands of your manufacturing processes.

- Quick Turnaround: Our efficient workflow and advanced machining technology allow us to complete tooling projects promptly, ensuring minimal delays.

- Flexible Order Volume: Whether you need a single tool or a large batch, we can accommodate your order volume requirements. No project is too big or too small for us.

Partnering with us means gaining access to a reliable CNC tooling service that prioritizes quality and customer satisfaction. We take pride in our attention to detail and commitment to delivering exceptional results.

Our dedicated team is here to support you throughout the tooling process, from design consultation to final production. Whether you need assistance with material selection, refining tooling specifications, or optimizing efficiency, we’re here to help.

“Precision Machining Pro has been our trusted partner for rapid CNC tooling. Their quick turnaround times and outstanding quality have greatly contributed to our production efficiency. We highly recommend their services.” – John Smith, Manufacturing Manager at XYZ Industries

For reliable and efficient CNC tooling services, turn to Precision Machining Pro. Visit precisionmachiningpro.com to learn more about our capabilities and submit a request for a quote. Experience the benefits of our rapid CNC tooling service for your next project.

Traditional Machining vs. CNC Machining

At Precision Machining Pro, we understand the importance of choosing the right machining method for your manufacturing needs. In this section, we will discuss the differences between traditional machining and CNC machining, highlighting the benefits of CNC machining in terms of precision and automation.

Traditional Machining

Traditional machining involves a skilled machinist manually operating machines to remove or form metal. It relies on the expertise of the machinist to follow specific instructions, interpret drawings, and use various tools to shape the material. While traditional machining methods have been used for many years and are still applicable in certain situations, they often require more time, manual intervention, and may have limitations in achieving precise results.

CNC Machining

CNC machining, on the other hand, utilizes computer numerical control to automate the machining process. It combines computer technology, mathematical coordinates, and computing power to achieve highly accurate results. CNC machines are programmed using code to follow the specifications provided by designers and engineers, eliminating the need for manual intervention and reducing the risk of human error.

“CNC machining offers greater precision and repeatability, making it the preferred method in manufacturing and industrial production. It provides a high level of control and consistency, resulting in reliable and accurate parts.”

With CNC machining, complex shapes and geometries can be achieved with ease, as the machines are capable of precise movements in multiple axes. This makes CNC machining suitable for producing intricate and custom-designed parts that require a high level of accuracy and consistency.

The Advantages of CNC Machining

CNC machining offers several advantages over traditional machining methods:

- Greater Precision: CNC machines can achieve extremely tight tolerances, ensuring consistent quality and precise dimensions.

- Automation and Efficiency: With CNC machining, the process is automated, reducing the need for manual labor and increasing production efficiency.

- Repeatability: CNC machines can produce identical parts consistently, ensuring reliable and repeatable results.

- Faster Turnaround: CNC machines can perform tasks at a faster rate compared to traditional machining, resulting in shorter lead times.

- Flexibility: CNC machines can easily be reprogrammed to produce different parts, making them highly versatile for various manufacturing needs.

By choosing CNC machining, you can benefit from its precision, automation, and the ability to produce high-quality parts with greater efficiency. At Precision Machining Pro, we specialize in CNC machining and have the expertise to deliver superior results for your manufacturing needs.

| Traditional Machining | CNC Machining |

|---|---|

| Manual operation by skilled machinists | Automated process driven by code |

| Human intervention and interpretation of instructions | Consistent and precise execution of specifications |

| May require more time for complex shapes and geometries | Efficient production of complex parts with ease |

| Potential for human error and inconsistencies | High level of control and consistency |

| Limitations in achieving tight tolerances | Capable of achieving extremely tight tolerances |

Quick-Turn Supplier of Machined Components

Precision Machining Pro is your trusted quick-turn supplier of machined plastic and metal components. With our unmatched capacity and extensive fleet of CNC machines, we can ensure that your parts are delivered on time, every time.

At Precision Machining Pro, we understand the importance of rapid prototyping and low-volume production. Our AS9100-certified facilities are specifically designed to cater to these needs, allowing us to deliver end-use components quickly and efficiently. With precise machining processes and rigorous quality control measures, we guarantee the highest standards of craftsmanship and reliability.

But what sets us apart is our digital network of manufacturers at Hubs. Through this network, you gain access to advanced machining capabilities, including tighter tolerances, volume pricing, and anodizing options, providing you with a comprehensive solution for all your machining requirements.

Why Choose Precision Machining Pro?

- Rapid turnaround times: With our quick-turn capabilities, we prioritize your project and ensure timely delivery.

- Unmatched capacity: Our vast fleet of CNC machines enables us to handle projects of any size and scale, meeting your exact specifications.

- AS9100-certified facilities: Our facilities meet stringent quality standards, ensuring that your components are manufactured to the highest levels of precision.

- Advanced machining capabilities: Through our network at Hubs, you gain access to cutting-edge technologies, allowing for tighter tolerances, volume pricing, and anodizing options.

Partnering with Precision Machining Pro means partnering with a company that values quality, precision, and customer satisfaction. Explore our website precisionmachiningpro.com to learn more about our services and how we can assist you with your machining needs.

“Precision Machining Pro delivers high-quality machined components with unmatched speed and precision. Their quick-turn capabilities and advanced machining options through their digital network at Hubs make them the go-to supplier for all our machining needs.” – [Client Name], [Company Name]

| Benefits of Precision Machining Pro | Features |

|---|---|

| Quick turnaround times | Efficiently meet your project deadlines |

| Unmatched capacity | Handle projects of any size and scale |

| AS9100-certified facilities | Ensure the highest quality standards |

| Advanced machining capabilities | Access cutting-edge technologies for tighter tolerances, volume pricing, and anodizing options |

CNC Machining Capabilities

At Precision Machining Pro, we have a wide range of CNC machining capabilities to meet your specific requirements. Whether you need small or large parts, we have the expertise and equipment to deliver excellent results.

Maximum Part Size:

Our factory capabilities allow us to produce parts with dimensions ranging from 0.25 in. x 0.25 in. to 22 in. x 14 in. This gives us the flexibility to handle a variety of project sizes and complexities.

Minimum Part Size:

For smaller parts, we can accommodate dimensions as small as 0.25 in. x 0.25 in. This precision enables us to manufacture intricate components with exceptional accuracy.

Tolerances:

At Precision Machining Pro, we maintain tight tolerances of +/- 0.005 in. This level of precision ensures that your parts meet the required specifications and function flawlessly.

In addition to size and tolerances, our CNC machining capabilities include the ability to produce sharp inside corners or radiused features. This allows for the creation of intricate designs and complex geometries.

Our state-of-the-art equipment, combined with our skilled team of machinists, ensures that we deliver high-quality, precise parts for your projects. Trust Precision Machining Pro for all your CNC machining needs.

| Capability | Range |

|---|---|

| Maximum Part Size | 0.25 in. x 0.25 in. to 22 in. x 14 in. |

| Minimum Part Size | 0.25 in. x 0.25 in. |

| Tolerances | +/- 0.005 in. |

Upload a Part for Quick Turnaround

At Precision Machining Pro, we make it seamless for you to get your parts manufactured with fast turnaround times. Simply upload your 3D CAD file to our website, precisionmachiningpro.com, and our experienced team will analyze it to provide you with a quick quote.

Our automated design analysis tools allow us to identify any difficult-to-machine features in your design and optimize the manufacturing process. This ensures that your parts are efficiently produced without compromising on quality.

When you choose Precision Machining Pro, you can rely on our domestic production and support. Our trusted U.S.-based manufacturing team is dedicated to delivering high-quality parts according to your specifications. With our infinite capacity, you won’t experience any downtime waiting for your parts.

Experience the convenience of uploading your part for fast delivery and exceptional manufacturing analysis. Trust Precision Machining Pro to bring your designs to life with precision and efficiency.

| Benefits of Uploading a Part for Quick Turnaround: |

|---|

| 1. Fast Quote: Get a quick quote by uploading your 3D CAD file. |

| 2. Manufacturing Analysis: Our automated design analysis will optimize the manufacturing process for efficient production. |

| 3. Domestic Production: Rely on our trusted U.S.-based manufacturing team for high-quality parts. |

| 4. Infinite Capacity: Experience fast delivery without any downtime waiting for your parts. |

Material Selection and Advanced Capabilities

We at Precision Machining Pro understand the importance of material selection in achieving optimal results for your machining projects. That’s why we offer a wide range of engineering-grade plastic and metal materials, carefully selected to suit various applications and industries.

Our material selection includes an array of plastics, such as ABS, polycarbonate, and nylon, known for their durability, versatility, and excellent impact resistance. For metal components, we provide options like aluminum and stainless steel, renowned for their strength, corrosion resistance, and thermal conductivity.

Through our extensive network of trusted manufacturers at Hubs, we can offer advanced capabilities, such as anodizing and tighter tolerances. Anodizing provides a protective surface finish, enhancing the corrosion resistance and aesthetic appeal of your parts. Tighter tolerances ensure precise and accurate dimensions, allowing for seamless integration into your assemblies and systems.

Whether you require specific properties, finishes, or tolerances, our varied material selection and advanced capabilities enable us to meet your unique machining requirements with precision and excellence.

Key Highlights:

- Wide range of engineering-grade plastic and metal materials

- Options include ABS, polycarbonate, nylon, aluminum, and stainless steel

- Anodizing for enhanced corrosion resistance and aesthetics

- Tighter tolerances for precise dimensions

Trust Precision Machining Pro for your material selection needs and benefit from our commitment to delivering high-quality machined parts perfectly tailored to your specifications.

Advantages of CNC Machining

CNC machining offers several advantages for both prototyping and production parts. At Precision Machining Pro, we utilize state-of-the-art equipment and cutting-edge technology to provide our customers with exceptional results. Here are the key advantages of CNC machining:

Precision and Repeatability

Our CNC machines are programmed to execute precise movements with utmost accuracy. This allows us to achieve precise dimensions and consistent quality across multiple parts. With CNC machining, you can expect high precision and repeatability, ensuring the reliability and performance of your machined parts.

Tight Tolerances for High-Quality Finishes

CNC machining enables us to work with tight tolerances, ensuring that your parts meet the required specifications. Our skilled machinists meticulously control the machining process to achieve high-quality finishes and accurate dimensions. Whether you need intricate details or fine surface finishes, our CNC machining capabilities can exceed your expectations.

Utilization of Production-Grade Materials

At Precision Machining Pro, we understand the importance of using production-grade materials to ensure the durability and functionality of your machined parts. Our CNC machines can handle a wide range of materials, including aluminum, steel, plastics, and composites. No matter the material requirements of your project, we have the expertise and capabilities to produce exceptional results.

With our precision machining services, you can trust us to deliver superior quality parts that meet your specific needs and requirements. From rapid prototyping to production runs, Precision Machining Pro is your trusted partner in achieving precision, tight tolerances, and high-quality results.

| Advantages of CNC Machining | Description |

|---|---|

| Precision and Repeatability | Ensures precise dimensions and consistent quality across multiple parts. |

| Tight Tolerances for High-Quality Finishes | Enables the achievement of fine surface finishes and accurate dimensions. |

| Utilization of Production-Grade Materials | Allows for the use of durable and functional materials for machined parts. |

Conclusion

Precision Machining Pro is the trusted partner for all your precision machining needs. Our commitment to excellence is reflected in our quick turnaround times, expert team, and advanced machining capabilities. No matter the complexity of your project, we have the expertise and resources to deliver high-quality custom parts that meet your exact specifications.

With our state-of-the-art CNC machining technology and our skilled technicians, we ensure precision and accuracy in every machined component. Whether you require rapid prototyping or low-volume production, our efficient and accurate machining services will meet your needs. Our dedication to customer satisfaction is unmatched, and we strive to deliver the highest quality parts on time, every time.

Contact us today at Precision Machining Pro to discuss your project requirements. Our team of professionals is ready to provide tailored solutions for your precision machining needs. Visit our website at precisionmachiningpro.com to learn more about our services and capabilities. Experience the difference of working with a reliable partner who prioritizes precision machining, CNC machining, and rapid turnaround.

FAQ

What is precision machining?

Precision machining is a manufacturing process that involves using advanced machinery, such as CNC machines, to create custom parts with high accuracy and tight tolerances.

What is CNC machining?

CNC machining, or computer numerical control machining, is a method of manufacturing that utilizes automated machines controlled by computer programs to produce precise and repeatable parts.

What services does Precision Machining Pro offer?

Precision Machining Pro offers expert precision machining services, including CNC milling, CNC turning, rapid prototyping, and custom machining for a variety of materials and industries.

What are the advantages of CNC milling?

CNC milling offers rapid prototyping capabilities and the ability to produce low-to-high volume production runs. It provides precise manufacturing and repeatability, making it suitable for a wide range of applications.

What are the benefits of CNC turning?

CNC turning allows for various operations like facing, threading, drilling, and taper turning. It saves time by eliminating costly setup and provides versatility to meet specific machining requirements.

What is CNC 5-axis machining?

CNC 5-axis machining is a method that uses advanced machines capable of producing parts with complex geometries. It minimizes machine setups and offers precise contouring and complex machining.

What is a rapid CNC tooling service?

A rapid CNC tooling service allows for the creation of hard tooling from different materials. It provides flexibility in terms of budgets, order volumes, and timeframes for production.

What is the difference between traditional machining and CNC machining?

Traditional machining involves manual operation by machinists, while CNC machining is automated and driven by computer programs. CNC machining offers greater precision, repeatability, and efficiency in the manufacturing process.

What makes Precision Machining Pro a quick-turn supplier?

Precision Machining Pro is a reliable quick-turn supplier of machined plastic and metal components. With our unmatched capacity and hundreds of CNC machines, we can ensure your parts are shipped on time, every time.

What are the CNC machining capabilities of Precision Machining Pro?

Precision Machining Pro can handle a wide range of part sizes and maintain tight tolerances. We can produce sharp inside corners or radiused features, suitable for both small and large machined parts.

How can I upload a part for quick turnaround?

You can upload your 3D CAD file to request a quote and receive a quick turnaround on your parts. Our automated design analysis will help optimize the manufacturing process.

What materials are available for machining at Precision Machining Pro?

Precision Machining Pro stocks over 30 engineering-grade plastic and metal materials suitable for various applications. Through our network of manufacturers, we can provide advanced capabilities such as anodizing and tighter tolerances.

What are the advantages of CNC machining?

CNC machining offers precision, tight tolerances, and the use of production-grade materials. It ensures consistent quality, high-quality finishes, and accurate dimensions in both prototyping and production parts.

Why should I choose Precision Machining Pro for my precision machining needs?

Precision Machining Pro is your reliable partner with quick turnaround times, expert teams, and advanced capabilities. Whether you need rapid prototyping or low-volume production, we can provide efficient and accurate machining services.